×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

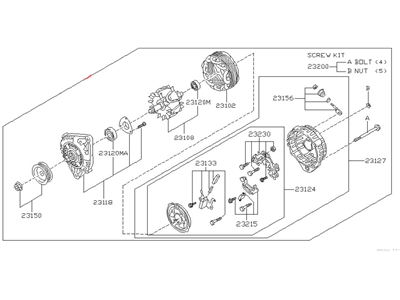

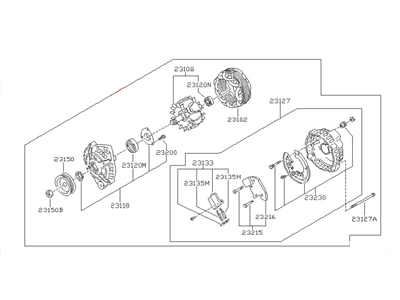

Genuine Nissan 240SX Alternator

Generator- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Alternators found

Nissan 240SX Alternator

If you need any OEM Nissan 240SX Alternator, feel free to choose them out of our huge selection of genuine Nissan 240SX Alternator. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Alternator Parts Questions & Experts Answers

- Q: What are the precautionary measures to prevent damage to the alternator and regulator when working with the electrical system on Nissan 240sx?A:When operating on the electrical system, it is important to handle batteries with care to prevent damage to the alternators and regulators. Examples are such as never connecting battery terminals in reverse, connecting booster batteries properly when starting up, remove battery cables before using fast charger, avoid using fast charger as a booster for starting vehicle, do not disconnect Voltage Regulator while engine is running, do not ground alternator output terminal, do not run alternator open circuited with field energized , do not try to polarize the alternator and take care that the assembly of the alternator is not exposed to excessive heat or moisture when steam cleaning an engine. To get out and put in an alternator it will be important that you disconnected negative battery terminal; disconnected lead wires and connector; loosened drive belt adjusting bolt and removed belt; unscrewed attaching bolts of the alternator; mounted alternator to the engine and partially tightened attaching bolts; returned lead wires and connector; installed drive belt for an alternator; made proper adjustment of an alternator belt and secure mounting bolts fully on it then finally connect cable from battery checking its operation. New brush holder assembly must be installed during overhaul process, front case of the rotor should be aligned then rear case should be installed in order to remove rotor and brush holder assembly. Before conducting an alternator test ensure that your battery is okay and well charged plus use a correct tester along with appropriate testing probes.