×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

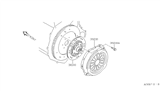

Genuine Nissan 240SX Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Clutch Discs found

Nissan 240SX Clutch Disc

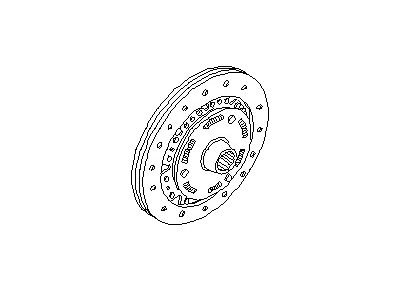

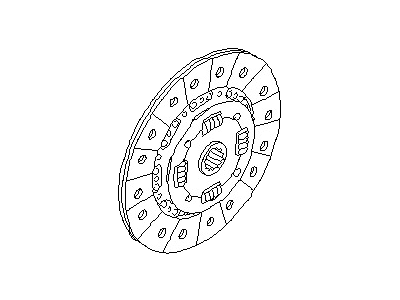

Through its function as a connecting element Nissan 240SX vehicles use the Clutch Disc to link the engine power with the transmission for controlled gear shifts. The two friction sides of the clutch connect both the flywheel and pressure plate to transmit engine power. Gear changes become possible when pressing the clutch pedal because the pressure plate separates from the Clutch Disc. Release of the clutch pedal lets the Clutch Disc automatically engage to establish power flow. Different types of Nissan Clutch Disc found in the 240SX lineup consist of organic materials and ceramic options as well as kevlar-based and sintered iron high-performance replacement s. People choose organic Clutch Disc as their go-to choice for daily driving although performance enthusiasts rely on ceramic Nissan Clutch Disc. The street performance hub design includes sprungs to reduce impacts but race applications need rigid hub 240SX replacement parts. Performance duration as well as long-term operational life is determined by the type of clutch materials applied so their tolerance to heat and their expected service lifespan will differ.

If you need any OEM Nissan 240SX Clutch Disc, feel free to choose them out of our huge selection of genuine Nissan 240SX Clutch Disc. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Clutch Disc Parts Questions & Experts Answers

- Q: How do you determine if you should replace the clutch cover, clutch disc, and pressure plate at the same time on Nissan 240sx?A:Clutch cover and pressure plate are stated to be in balance when considered as assembly thus when either of the part is worn out or damaged both the parts and the release bearing must be replaced. Cracks in the flywheel should also be looked for, and then it should be turned or replaced depending on its condition and the torque applied on the flywheel retaining bolts. Starting from the fact that, with the engine having been installed, the next step is pulling the transmission/transaxle out of the engine fully. Depress the clutch disc hub and place a barring such as clutch aligning bar or similar tool underneath to support it while it is removed. Most of the clutch manufacturers put a match mark on the assembly to ensure that the assembly and flywheel get a correct fit when replaced. Remove the bolts in order starting with the first bolt until all the bolts have been removed then you can remove the pressure plate and clutch disc. The release mechanism of the transmission housing when pulling the shift lever using a set screw, grease the identified contact points with lithium based molybdenum disulfide grease. Remove the release bearing and if worn replace it, and after applying a little grease to the splines of the transmission, place the clutch disc back in the contact and move forward and backward to spread the grease. Scrape off any extra grease, replace the clutch disc on the flywheel through using an alignment tool and put the pressure plate and fasten the bolts in a mix up diagonal order to 16-22ft-lbs. Last, take out the dummy shaft and install the new/reconstructed/repaired/troubleshooted transmission/transaxle, and test the system for its functionality.