×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 240SX Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Oxygen Sensors found

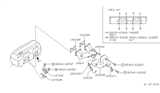

Nissan 240SX Oxygen Sensor

If you need any OEM Nissan 240SX Oxygen Sensor, feel free to choose them out of our huge selection of genuine Nissan 240SX Oxygen Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Oxygen Sensor Parts Questions & Experts Answers

- Q: How to replace the oxygen sensor in Nissan 240sx?A:The vehicle's exhaust gas sensor warning light on the instrument panel tells a driver that the oxygen sensor must be replaced once the car has driven 30,000 miles. You should change your oxygen sensor every 30,000 miles to achieve a good mixture of air and fuel in an engine. The following service procedure is recommended by Nissan Motor Company for all models up to 1987 year after which complete Engine Self-Diagnosis will be required. To inspect the oxygen sensor, start the engine and let it reach normal operating temperature. Run the engine at about 2,000 rpm with no load, blocking the front wheels and setting the parking brake. There is an inspection lamp at the bottom of control unit located in passenger compartment; when oxygen sensor is functioning properly, this inspection lamp will cycle on and off more than nine times in ten seconds. It may be helpful to view this light using a mirror. If there is any deviation from these instructions by not lighting or going off as stipulated by specifications of a faulty system, then further checking ought to be conducted such as battery test, ignition system check up, oil level and coolant level in engine block, correct fuses in place, fuel injection wiring harness connectors must be intact without any damage visible on them, all vacuum hoses attached securely if not they have been lost yet others that are coolants must also fitted tightly on their respective places otherwise even a drop of oil will not get through to lubricate engines parts apart from dipstick that needs to be checked for enough oil inside it also valve clearance is measured whereby if it's too tight due to neglecting its maintenance one will find difficultly starting his cars until he adjusts it again finally he will check engine compression which depends largely on how well you drive your vehicle because if you looking after properly then there should'nt have any problems so long as all bolts are tightened equally nothing would align again unless some kind of mechanical failure occurs sometimes caused by either human error or manufacturing flaws especially during installation process when these devices incorrectly fitted which means that something could go wrong without anyone knowing what exactly happened next time they turn on their engines because one would have forgotten about this incident until it resurfaced causing irreparable damage to some parts such as piston rings meanwhile others like bearings also get affected eventually leading complete breakdown of engine itself; and finally misuse oils used as well as choice wrong type lubricants also will play crucial role determining lifespan particular machine called 'oxygen' its cognitive ability is questionable hence it has not been recommended that people should avoid using anything else except what is specified by manufacturer in order prolonging life span whilst protecting your investment against future problems related aging components resulted from abuse oil. In case the lamp fails to cycle correctly even after checking all these things, then most likely the problem is with the oxygen sensor. However, you must consider the fuel injection control unit's failure; thus, if there is any doubt, one should take it to professional mechanics who have experience with "Mixture Ratio Feedback System" for examination purposes. To replace the oxygen sensor, disconnect the negative battery cable and remove the electrical lead from the sensor afterwards unscrew it from the exhaust manifold. Apply a nickel-based anti-seize compound on threads of a replacement (avoid those other compounds which may insulate instead). Connect cable again but take care while doing so not cause harm on it before attaching battery's ground wiring back into place. Take care and don't drop or handle this part roughly also never let any stuff touch its surface.