×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 240SX Steering Wheel

Navigation Steering Wheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Steering Wheels found

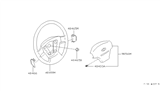

Nissan 240SX Steering Wheel Assembly W/O Pad

Part Number: 48430-51F00$527.86 MSRP: $813.35Limited AvailabilityYou Save: $285.49 (36%)

Nissan 240SX Steering Wheel

If you need any OEM Nissan 240SX Steering Wheel, feel free to choose them out of our huge selection of genuine Nissan 240SX Steering Wheel. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Steering Wheel Parts Questions & Experts Answers

- Q: How do you remove and install the steering wheel on Nissan 240sx?A:When the steering wheel has to be adjusted the wrench has to be placed in a way that stears are straight ahead with the steering wheel upright and level. Loosen the connection at the nut junction between the battery terminals and the battery buss bar. Look at the back of the wheel; if there are countersunk screws in the spokes, then use the screw driver to undo them and pull out the horn pad causing any horn wire to be detached if present. Note that horn buttons of particular vehicles may be disconnected in different ways through pulling off, pulling off and pushing up or pushing in and rotating anticlockwise. For newer models in case the horn pad is hard to take out, one can slightly unscrew the fixing screw adjacent to the steering wheel. Then, also, only if the horn switching mechanism hinders the wheel removal process, remove it along with other parts and keep a record of their placement. With reference to the position where the Column shaft and the steering wheel flange aligns with each other, mark it. Lose the attaching nut and fit an appropriate puller to make the steering wheel off; it is advisable not to hit the shaft hard since the column may fold. During reinstallation reverse the sequence through which they were removed while ensuring that the marks created previously as reference are used to aid reinstallation, it is also recommended to apply multipurpose grease on the turn signal canceling pin and horn contact slip ring as well. Do not drive or force the wheel to set in place hard, for this will harm the collapsible steering column. Last, tighten the fastener that secured the steering wheel to the specified torque and replace the horn button, pad, or ring, and test the system for functionality. The torque specifications for the steering wheel retaining nut may differ depending on the year and the model to be worked on, and specific torque ranges should be used as described below.