×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Altima Spark Plug

Ignition Spark Plug- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Spark Plugs found

Nissan Altima Spark Plug

Part Number: 22401-EW61C$20.25 MSRP: $29.33You Save: $9.08 (31%)Ships in 1-2 Business Days

Nissan Altima Spark Plug

Part Number: 22401-JA01B$20.82 MSRP: $30.15You Save: $9.33 (31%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-5M014$14.93 MSRP: $21.62You Save: $6.69 (31%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-5M015$14.60 MSRP: $21.15You Save: $6.55 (31%)Ships in 1-2 Business Days

Nissan Altima Spark Plug

Part Number: 22401-5M016$12.98 MSRP: $18.80You Save: $5.82 (31%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-6CA1C$21.14 MSRP: $30.62You Save: $9.48 (31%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-5NA1C$28.85 MSRP: $46.80You Save: $17.95 (39%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-50Y06$3.48 MSRP: $5.65You Save: $2.17 (39%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

Part Number: 22401-7B005$14.87 MSRP: $21.53You Save: $6.66 (31%)Ships in 1-3 Business Days

Nissan Altima PLUG-SPARK

Part Number: 22401-6LD1C$21.14 MSRP: $30.62You Save: $9.48 (31%)Ships in 1-3 Business DaysNissan Altima Spark Plug

Part Number: 22401-50Y05$4.44 MSRP: $6.43You Save: $1.99 (31%)Ships in 1-3 Business DaysNissan Altima Spark Plug

Part Number: 22401-1P117$19.11 MSRP: $27.68You Save: $8.57 (31%)Ships in 1-3 Business DaysNissan Altima Spark Plugs

Part Number: 22401-EW61B$20.40 MSRP: $29.55You Save: $9.15 (31%)Ships in 1-3 Business Days

Nissan Altima Spark Plug

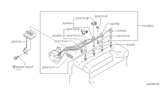

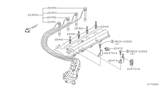

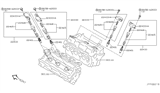

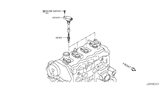

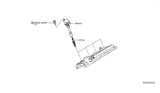

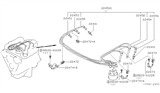

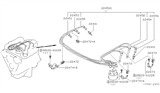

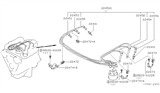

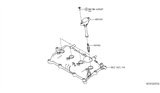

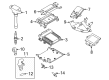

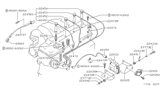

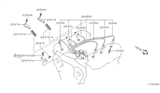

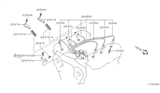

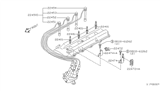

This item known as Nissan Altima Spark Plug plays an important role of boosting up the performances of the Nissan of automobiles. As a device with a threaded end that is screwed into the engine's combustion chamber, Spark Plug has been designed to enable the ignition of air-fuel mixture in the engine's combustion chamber through the provision of high voltage electric current required for sparking. Year after year, several forms of Spark Plug have been incorporated into different models, through copper/nickel, platinum, double platinum, and iridium Spark Plug that have different qualities in terms of longevity and efficiency. The Spark Plug should be selected according to the engine type, as they affect the combustion overview and any misfires and poor acceleration. To enhance the efficiency and safety of driving, the Nissan Spark Plug should be replaced often, to keep the car in its highly shape. Specifically, the Nissan Spark Plug serves various types of the Altima, hence is convenient for car owners who want to improve their Altima's productivity. It is durable, efficient, and of high quality due to such characteristics as the use of platinum and iridium materials among others, which set it apart from other Spark Plug found in automobiles. Finally, it can be summarized that the importance of Nissan Spark Plug in providing the reliability and performance that are expected from drivers makes it one of the highly dependable choices for the mid-sized car market, particularly for the Altima.

If you need any OEM Nissan Altima Spark Plug, feel free to choose them out of our huge selection of genuine Nissan Altima Spark Plug. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Altima Spark Plug Parts Questions & Experts Answers

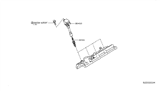

- Q: What does the manufacturer advise regarding checking the spark plug gap on Nissan Altima with platinum- or iridium-tipped plugs?A:According, the manufacturer does not recommend checking the spark plug gap on the vehicles equipped with the platinum- or iridium-tipped spark plugs since the said type of finish is quite fragile and can be easily damaged during the process, thus drastically reducing the said type of plugs' duration. The tools needed to change spark plugs include a spark plug socket that should be extended with a study ratchet, a wire type feeler gauge that is used to check gap on the new spark plugs and torque wrench that is used to tighten new spark plugs. During the process of replacing plugs, acquire new plugs, set individual plugs to the appropriate gap, and then change plugs singularly. Exam new plugs for imperfections, make certain that there are no cracks on the porcelain insulator of the plug. Using the wire gauge, measure the gaps of the electrodes; if any adjustments are required be sure to bend the side electrode and not harm the porcelain insulator. Make sure that the side electrode is corresponding to the central one, and if the base of the ground electrode rotated to side, rotate only the base of it. Before removing the spark plug, blow all the dirt or debris with compressed air around the spark plug area. For a 4-cylinder engine, the ignition coils have to be removed followed by the spark plugs using the sockets. While for a V6 engine, it is recommended that the upper intake manifold and ignition coils to be first to be removed, accompanied by the spark plugs. In either case, examine the old plugs in relation to a specified guide to determine the general status of the engine. lubricate the plug threads with anti-seize compound prior to installation but do not apply it to the lower threads; if forcing the spark plug through the rubber hose should be tightly over the spark plug to prevent cross-threading. Continue threading the plugs and then transmit the plug with the desired torque and repeat this to the other plugs. Once all plugs are replaced, reinstallation of the ignition coils should be done.

Related Nissan Altima Parts

Browse by Year

2025 Spark Plug 2024 Spark Plug 2023 Spark Plug 2022 Spark Plug 2021 Spark Plug 2020 Spark Plug 2019 Spark Plug 2018 Spark Plug 2017 Spark Plug 2016 Spark Plug 2015 Spark Plug 2014 Spark Plug 2013 Spark Plug 2012 Spark Plug 2011 Spark Plug 2010 Spark Plug 2009 Spark Plug 2008 Spark Plug 2007 Spark Plug 2006 Spark Plug 2005 Spark Plug 2004 Spark Plug 2003 Spark Plug 2002 Spark Plug 2001 Spark Plug 2000 Spark Plug 1999 Spark Plug 1998 Spark Plug 1997 Spark Plug 1996 Spark Plug 1995 Spark Plug 1994 Spark Plug 1993 Spark Plug