×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Juke Clutch Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Clutch Master Cylinder found

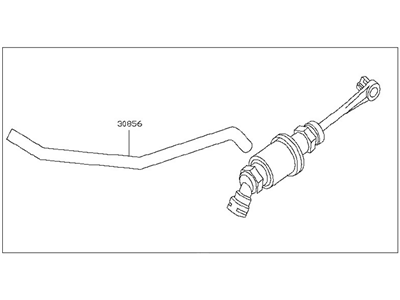

Nissan Juke Clutch Master Cylinder Assembly

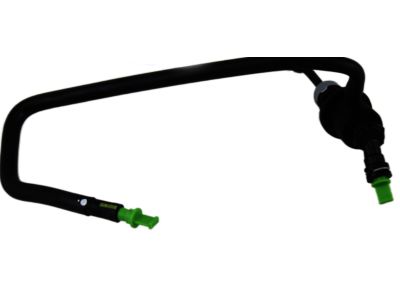

Part Number: 30610-1KM0A$94.77 MSRP: $137.25You Save: $42.48 (31%)Ships in 1-3 Business Days

Nissan Juke Clutch Master Cylinder

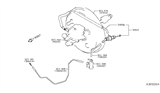

The master cylinder commonly referred to as Clutch Master Cylinder in Nissan Juke automobiles is an essential component that develops the hydraulic pressure necessary to take the clutch when the clutch pedal is squeezed. This hydraulic pressure is then transferred to the slave cylinder and this helps the clutch to release and shift the gears. Some of the symptoms that might indicate that the Clutch Master Cylinder is faulty include; a soft pedal, clutch fluid leakage and hard gear shifting. Casting cylinder can create a gap which may be as a result of worn seals or cylinder bores may also lead to rust and moisture picked up by hydraulic fluid. The Clutch Master Cylinder has the vital responsibility of regulating the existence and functionality of the transmission mechanism in the automobiles, brake as well as the clutch.

If you need any OEM Nissan Juke Clutch Master Cylinder, feel free to choose them out of our huge selection of genuine Nissan Juke Clutch Master Cylinder. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Juke Clutch Master Cylinder Parts Questions & Experts Answers

- Q: How to disconnect and reconnect the clutch master cylinder on Nissan Juke?A:Disconnect the battery negative terminal. Using a flat bladed screwdriver, prise the clutch master cylinder pushrod end from the clutch pedal pin. To minimise hydraulic fluid loss, remove the brake master cylinder reservoir filler cap then tighten it down onto a piece of polythene to obtain an airtight seal. Remove the windscreen cowl panel and cowl panel extension. On diesel engine models, move the fuel supply and return hoses to one side to provide greater access. Place absorbent rags under the clutch master cylinder pipe connections in the engine compartment and be prepared for some hydraulic fluid loss. Clamp the upper hydraulic fluid supply hose leading from the brake fluid reservoir to the clutch master cylinder using a brake hose clamp. Release the clutch master cylinder hydraulic pressure pipe from the retaining clip on the engine compartment bulkhead, then prise out the retaining wire clip and disconnect the pipe from the clutch master cylinder. Be prepared for some hydraulic fluid loss and disconnect the fluid supply hose from the top of the clutch master cylinder. Rotate the clutch master cylinder 45 degrees clockwise, and remove it from the bulkhead. Refitting the clutch master cylinder is the reverse sequence to removal, ensuring that the pedal-to-master cylinder pushrod is correctly fitted, all retaining clips are correctly refitted, the windscreen cowl panel and cowl panel extension are refitted, the piece of polythene from the top of the reservoir is removed, and on completion, the clutch hydraulic system is bled.