×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

78 Coil Springs found

Nissan Maxima Front Spring

Part Number: 54010-4RA1A$227.83 MSRP: $321.80You Save: $93.97 (30%)Ships in 1-3 Business Days

Nissan Maxima Front Spring

Part Number: 54010-ZX70A$130.13 MSRP: $183.80You Save: $53.67 (30%)Ships in 1-3 Business Days

Nissan Maxima Rear Suspension Spring

Part Number: 55020-9N10B$119.36 MSRP: $168.58You Save: $49.22 (30%)Ships in 1-3 Business Days

Nissan Maxima Rear Suspension Spring

Part Number: 55020-7Y001$169.44 MSRP: $239.32You Save: $69.88 (30%)Ships in 1-3 Business Days

Nissan Maxima Front Spring

Part Number: 54010-ZY80A$212.00 MSRP: $299.43You Save: $87.43 (30%)Ships in 1-3 Business Days

Nissan Maxima Front Spring

Part Number: 54010-9J410$125.47 MSRP: $172.82You Save: $47.35 (28%)Ships in 1-2 Business Days

Nissan Maxima Rear Suspension Spring

Part Number: 55020-4RA3A$92.17 MSRP: $130.18You Save: $38.01 (30%)Ships in 1-3 Business DaysNissan Maxima Rear Suspension Spring

Part Number: 55020-9N60B$70.04 MSRP: $98.93You Save: $28.89 (30%)Ships in 1-3 Business DaysNissan Maxima Rear Suspension Spring

Part Number: 55020-4RA3B$92.17 MSRP: $130.18You Save: $38.01 (30%)Ships in 1-3 Business DaysNissan Maxima Rear Suspension Spring

Part Number: 55020-4RA2A$110.00 MSRP: $155.37You Save: $45.37 (30%)Ships in 1-3 Business DaysNissan Maxima Front Spring

Part Number: 54010-4RA0B$230.65 MSRP: $325.78You Save: $95.13 (30%)Ships in 1-3 Business DaysNissan Maxima Rear Suspension Spring

Part Number: 55020-4RC2A$125.98 MSRP: $177.93You Save: $51.95 (30%)Ships in 1-3 Business DaysNissan Maxima Spring Front RH

Part Number: 54010-7Y011$103.62 MSRP: $159.65You Save: $56.03 (36%)Ships in 1-2 Business DaysNissan Maxima Front Spring

Part Number: 54010-7Y310$144.95 MSRP: $204.73You Save: $59.78 (30%)Ships in 1-3 Business DaysNissan Maxima Spring Rear Suspension

Part Number: 55020-2Y423$144.02 MSRP: $221.91Limited AvailabilityYou Save: $77.89 (36%)Nissan Maxima Rear Suspension Spring

Part Number: 55020-4RC2B$125.98 MSRP: $177.93You Save: $51.95 (30%)Ships in 1-3 Business DaysNissan Maxima Front Spring

Part Number: 54010-4RA0A$230.65 MSRP: $325.78You Save: $95.13 (30%)Ships in 1-3 Business DaysNissan Maxima Spring Rear Suspension

Part Number: 55020-2Y421$144.02 MSRP: $221.91Limited AvailabilityYou Save: $77.89 (36%)Nissan Maxima Rear Suspension Spring

Part Number: 55020-3Y000$158.79 MSRP: $224.28Limited AvailabilityYou Save: $65.49 (30%)Nissan Maxima Front Spring

Part Number: 54010-2Y108$103.70 MSRP: $159.78Limited AvailabilityYou Save: $56.08 (36%)

| Page 1 of 4 |Next >

1-20 of 78 Results

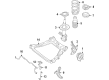

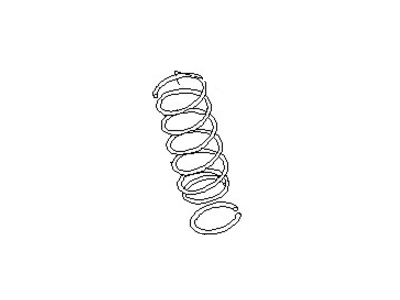

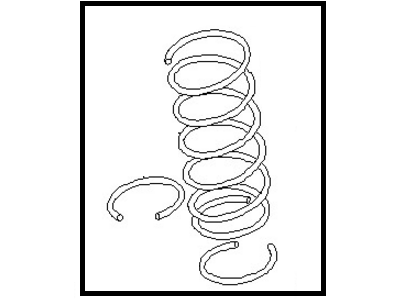

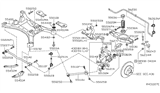

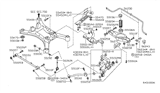

Nissan Maxima Coil Springs

The Nissan Maxima Coil Springs is one of the essential car suspension parts known to offer the prime reliability and performance. These common coil springs are used to help reduce the impact of some ride irregularities; they are made of metals and alloys, and are made using hot-winding or cold-winding. Some of the components of the Maxima suspension system include coil springs that are of variable and constant rate, shot peening, and thermal hardening of the suspension parts make them stronger and perform better due to these treatments. These coil springs are very essential in the provision of vehicle stability, comfort, and safety due to the force exerted while driving. These coil springs are compatible with the different generations of the Nissan Maxima especially the eighth generation where they will provide unique solutions to the different models enhancing on the efficiency of the car. Together with the car's distinctiveness, its three and a half-liter V6 power plant gives capability a boost as do its coil springs which are tuned to their ideal rates of stiffness and travel. This integration does not only improve the aspects of using the car for driving but also adds to the belief of the car as a sports luxury. Newer models offer specific features like lightweight yet strong construction that enhances the vehicle's ability to be controlled and maneuvered; in this context, Nissan Maxima Coil Springs set the bar for superior components in auto parts industry. In summary, these coil springs are crucial to the car's performance and durability that a Nissan Maxima driver would want.

If you need any OEM Nissan Maxima Coil Springs, feel free to choose them out of our huge selection of genuine Nissan Maxima Coil Springs. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Coil Springs Parts Questions & Experts Answers

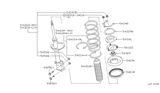

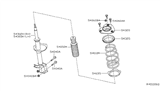

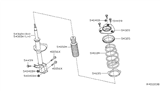

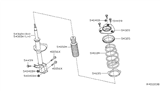

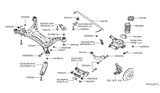

- Q: What are the steps involved in disassembling and reassembling a strut and coil spring assembly on Nissan Maxima?A:If the struts or coil springs show signs of wear such as leaking fluid, loss of damping capability, or physical damage, explore all options before starting any work, as strut/shock absorber assemblies are not serviceable and must be replaced if issues arise. Strut assemblies with springs may be available on an exchange basis, which can save time and effort. Always check the cost and availability of parts prior to disassembling the vehicle. Disassembling a strut can be dangerous, so focus on the task to avoid serious injury, using only a high-quality spring compressor and adhering to the manufacturer's instructions. After removing the coil spring from the strut assembly, place it in a safe area. To disassemble, remove the strut and spring assembly, mount it in a vise lined with wood or rags, and avoid excessive tightening. Install the spring compressor according to the manufacturer's instructions and compress the spring until all pressure is relieved from the upper spring seat, which can be verified by wiggling the spring. Remove the piston rod nut and the upper mount, inspecting the bearing for smooth operation and checking the rubber portion for deterioration. Lift the spring seat and upper insulator from the piston rod, checking the rubber spring seat for damage. Carefully lift the compressed spring from the assembly, ensuring the ends are pointed away from your body, and slide the dust boot off the piston rod. Check the lower insulator for wear and replace it if necessary. For reassembly, if replacing the lower insulator, position it correctly and extend the damper rod to its full length before installing the dust boot. Place the coil spring onto the lower insulator, ensuring the end fits into the recessed portion. Install the upper insulator and spring seat, ensuring the cutout on the spring seat faces outward, then install the dust seal and upper mount to the piston rod. Finally, install the nut and tighten it to the specified torque before reattaching the strut/shock absorber and coil spring assembly.

Related Nissan Maxima Parts

Browse by Year

2023 Coil Springs 2022 Coil Springs 2021 Coil Springs 2020 Coil Springs 2019 Coil Springs 2018 Coil Springs 2017 Coil Springs 2016 Coil Springs 2014 Coil Springs 2013 Coil Springs 2012 Coil Springs 2011 Coil Springs 2010 Coil Springs 2009 Coil Springs 2008 Coil Springs 2007 Coil Springs 2006 Coil Springs 2005 Coil Springs 2004 Coil Springs 2003 Coil Springs 2002 Coil Springs 2001 Coil Springs 2000 Coil Springs 1999 Coil Springs 1998 Coil Springs 1997 Coil Springs 1996 Coil Springs 1995 Coil Springs 1994 Coil Springs 1993 Coil Springs 1992 Coil Springs 1991 Coil Springs 1990 Coil Springs 1989 Coil Springs 1988 Coil Springs 1987 Coil Springs 1986 Coil Springs 1985 Coil Springs