×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Distributor Cap

Ignition Distributor Cap- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Distributor Caps found

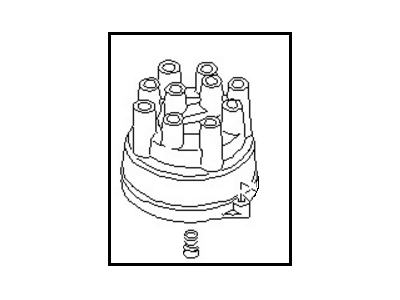

Nissan Maxima Cap Distributor

Part Number: 22162-16E04$42.45 MSRP: $58.52You Save: $16.07 (28%)Ships in 1-3 Business DaysNissan Maxima Cap Distributor

Part Number: B2162-16E00$42.45 MSRP: $58.52Limited AvailabilityYou Save: $16.07 (28%)Nissan Maxima Cap Distributor

Part Number: 22162-16E05$42.45 MSRP: $58.52Limited AvailabilityYou Save: $16.07 (28%)Nissan Maxima Cap Distributor

Part Number: 22162-16E03$42.45 MSRP: $58.52Limited AvailabilityYou Save: $16.07 (28%)

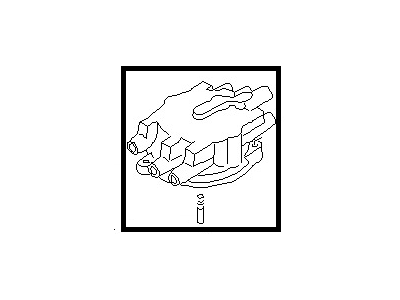

Nissan Maxima Distributor Cap

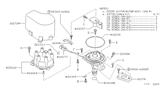

The Distributor Cap is a Nissan Maxima spark plug part that in one way or the other affects different Nissan Maxima models, ignition systems. This cap must distribute the energy from the ignition coils to the engine guaranteeing that high voltage electricity is conducting to the spark plug with the correct firing sequence that is important in firing fuel. Originally, the Distributor Cap has the function of shielding the inner elements of the distributor with a goal of improving the safety and performance of the automobile. Different styles of distributor caps have been implemented throughout Nissan Maxima autos due to changes that have occurred in the regarding ignition mechanisms and the caps themselves. It is highly recommended that the Distributor Cap be checked and changed frequently because of circumstances like exposure to water, heat, accumulation of carbon, and other unwanted elements can cause failure of the vehicle's engine. By doing so, the reliability of Nissan Maxima is further strengthened by this component meaning that the driver of the car is assured of the prime of the engine. More to the point, the posts of Distributor Cap are designed to be complementary to each cylinder of the engine and all sorts of ignition systems can be integrated rather effectively. It would therefore be highly recommended for the automotive market because it improves the drive whilst maintaining the stringent company quality of Nissan. The Distributor Cap is among the many valued components that ensure the Nissan Maxima lineup to be long-lasting and high-performing.

If you need any OEM Nissan Maxima Distributor Cap, feel free to choose them out of our huge selection of genuine Nissan Maxima Distributor Cap. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Distributor Cap Parts Questions & Experts Answers

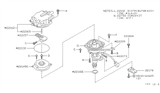

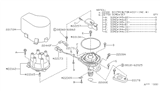

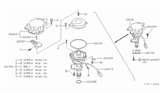

- Q: How do you inspect and replace spark plug wires,Distributor Cap and Distributor Rotor on Nissan Maxima?A:The Spark Plug wires should be checked whenever new spark plugs are installed, starting with a visual inspection while the engine runs in a darkened, ventilated area to observe for arcing or sparks at any damaged areas. Each wire must be inspected individually to maintain the correct order for proper engine operation, and original wires should be numbered for identification; if numbers are illegible, tape can be used to mark them. To disconnect a wire, use a removal tool or twist and pull the rubber boot without tugging on the wire itself, then check for corrosion inside the boot. After ensuring a tight fit on the spark plug, clean the wire with a rag, inspecting for burns or cracks without bending it sharply. Disconnect the wire from the distributor by pulling on the boot, checking for corrosion and fit before replacing it. Inspect all spark plug wires to ensure they are securely fastened at both ends. If new wires are needed, purchase a set specific to the engine model, replacing them one at a time to avoid mix-ups. Detach the distributor cap by loosening the screws, checking for cracks and worn contacts inside, and examine the rotor for damage, replacing both if necessary. It is advisable to install a new cap and rotor with new wires, but if the old cap is retained, check the resistance between the wires and the cap. When installing a new cap, transfer the wires from the old cap one at a time to maintain the correct firing order.