×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Flywheels found

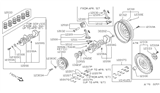

Nissan Maxima Flywheel Assembly

Part Number: 12310-8J100$409.74 MSRP: $578.73You Save: $168.99 (30%)Ships in 1-3 Business Days

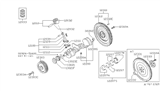

Nissan Maxima Drive & Gear Plate Assembly

Part Number: 12331-JA10C$181.51 MSRP: $256.37You Save: $74.86 (30%)Ships in 1-2 Business DaysNissan Maxima Flywheel Assembly

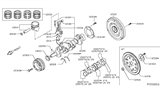

Part Number: 12310-40U21$406.89 MSRP: $547.33Limited AvailabilityYou Save: $140.44 (26%)Nissan Maxima Flywheel Assembly

Part Number: 12310-40U10$406.89 MSRP: $547.33Limited AvailabilityYou Save: $140.44 (26%)Nissan Maxima Flywheel Assembly

Part Number: 12310-40U00$406.89 MSRP: $547.33Limited AvailabilityYou Save: $140.44 (26%)

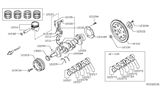

Nissan Maxima Flywheel Assembly

Part Number: 12310-40U20$406.89 MSRP: $547.33You Save: $140.44 (26%)

Nissan Maxima Flywheel Assembly

Part Number: 12310-2Y910$406.89 MSRP: $547.33You Save: $140.44 (26%)

Nissan Maxima Flywheel

If you need any OEM Nissan Maxima Flywheel, feel free to choose them out of our huge selection of genuine Nissan Maxima Flywheel. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Flywheel Parts Questions & Experts Answers

- Q: How do you properly remove and reinstall a flywheel or driveplate on Nissan Maxima with DOHC engine?A:Raise the vehicle and support it securely on jackstands. If equipped with a manual transaxle, remove the pressure plate and clutch disc, taking the opportunity to check or replace the clutch components and pilot bearing if necessary. For vehicles with an automatic transaxle, check and replace the front pump seal or O-ring. Use paint or a center-punch to make alignment marks on the flywheel or driveplate and crankshaft to ensure correct alignment during reinstallation. Remove the bolts securing the flywheel or driveplate to the crankshaft, and if the crankshaft turns, hold the flywheel or driveplate with a pry bar or jam a screwdriver into the ring gear teeth. Carefully remove the flywheel or driveplate from the crankshaft, supporting it while removing the last bolt due to its weight. Clean the flywheel to remove grease and oil, inspecting the surface for cracks, rivet grooves, burned areas, and score marks, with light scoring removable using emery cloth. Check for cracked or broken ring gear teeth or a loose ring gear, laying the flywheel on a flat surface to check for warpage with a straightedge. Clean and inspect the mating surfaces of the flywheel or driveplate and crankshaft, replacing the crankshaft rear seal if leaking before reinstalling. Position the flywheel or driveplate against the crankshaft, aligning the marks made during removal, and noting any alignment dowels or staggered bolt holes for correct installation. Apply thread locking compound to the bolt threads before tightening, using a screwdriver wedged into the ring gear teeth to prevent turning. Complete the installation by reversing the removal process.

Related Nissan Maxima Parts

Browse by Year

2023 Flywheel 2022 Flywheel 2021 Flywheel 2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2007 Flywheel 2006 Flywheel 2005 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1996 Flywheel 1995 Flywheel 1994 Flywheel 1993 Flywheel 1992 Flywheel 1991 Flywheel 1990 Flywheel 1989 Flywheel 1988 Flywheel 1987 Flywheel 1986 Flywheel 1985 Flywheel