×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

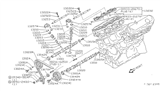

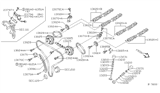

Genuine Nissan Maxima Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Intake Valves found

Nissan Maxima Valve Intake

Part Number: 13201-4W001$31.06 MSRP: $42.82You Save: $11.76 (28%)Ships in 1-3 Business DaysNissan Maxima Valve Intake

Part Number: 13201-9HP0A$10.77 MSRP: $14.85You Save: $4.08 (28%)Ships in 1-3 Business DaysNissan Maxima Intake Valve

Part Number: 13201-2Y900$11.09 MSRP: $15.28You Save: $4.19 (28%)Ships in 1-3 Business DaysNissan Maxima Intake Valve

Part Number: 13201-4W000$31.06 MSRP: $42.82You Save: $11.76 (28%)Ships in 1-3 Business Days

Nissan Maxima Intake Valve

If you need any OEM Nissan Maxima Intake Valve, feel free to choose them out of our huge selection of genuine Nissan Maxima Intake Valve. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Intake Valve Parts Questions & Experts Answers

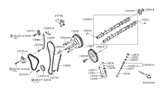

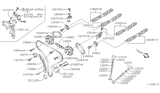

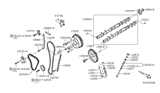

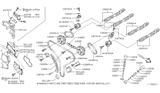

- Q: How to adjust valve clearances using special valve lifter tools on Nissan Maxima?A:Specific to the procedure is that the valve lifter tools need to be employed and the advanced type of these valves cannot be adjusted without these, which are available from specialty tool manufacturers and at auto parts stores. Start with the removal of the cable from the negative terminal of the battery in addition to the removal of the valve cover. On the models of cars that are equipped with a manual transaxle, engage the parking brake and shift the transaxle into neutral. The cylinder head must be open again to have the spark plugs relocated; the No 1 piston should be at TDC and on the compression stroke with the marketer of the PK initialization. Check the thickness of the indicated valves with a feeler gauge and record down each of the measurements ;then mark all those that are out of the manufacturers' specifications so that during the course of the exercise of determining the appropriate replacement shims, they may be used. Rotate the crankshaft 240 degrees clockwise to the Top Dead Centre on the compression stroke to get the number 3 cylinder, it's time to check and note the clearances of the following indicated valves. Do this again by rotating the crankshaft 240 degrees clockwise so that the number 5 cylinder is again at TDC and take the clearances. Following adjustment of all the values of clearance , rotate the crank shaft pulley so that the lobe of the cam-shaft above the first valve required for adjustment stands up from the lifter. Turn the hole in the valve shim in such a manner that it is in the center of the cylinder head casting, insert the special tool for lifting the valves and by pressing down the valve lifter, rotate the tool counterclockwise, away from the camshaft. Push with a small tool located between the lifter and the camshaft, lift the lifter and extract the adjusting shim with help of a small screwdriver and a magnet or a tweezers, use the compressed air if necessary, to remove the shim. Take the thickness of the shim with a micrometer, and then to determine the proper thickness of the new shim, apply the mathematical equations to intake and exhaust sides. Choose a shim with the thickness as close to the calculated valve clearance as possible, where shims are produced in 64 types and increments of 0.0004-inch. Perhaps a shim that has to be removed can be transferred to another valve lifter where it's required hence minimizing the number of new shims that one has to order. Insert special valve lifter tools in place, and put down the valve lifter, and place the new adjusting shim in its place: but make a clearance check with feeler gauge. This should be done until all valves that are out of specification are fixed, after which, reverse the above process.

Related Nissan Maxima Parts

Browse by Year

2023 Intake Valve 2022 Intake Valve 2021 Intake Valve 2020 Intake Valve 2019 Intake Valve 2018 Intake Valve 2017 Intake Valve 2016 Intake Valve 2014 Intake Valve 2013 Intake Valve 2012 Intake Valve 2011 Intake Valve 2010 Intake Valve 2009 Intake Valve 2008 Intake Valve 2007 Intake Valve 2006 Intake Valve 2005 Intake Valve 2004 Intake Valve 2003 Intake Valve 2002 Intake Valve 2001 Intake Valve 2000 Intake Valve 1999 Intake Valve 1998 Intake Valve 1997 Intake Valve 1996 Intake Valve 1995 Intake Valve 1994 Intake Valve 1993 Intake Valve 1992 Intake Valve 1991 Intake Valve 1990 Intake Valve 1989 Intake Valve 1988 Intake Valve 1987 Intake Valve 1986 Intake Valve 1985 Intake Valve