×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Timing Belts found

Nissan Maxima Belt-Timing

Part Number: 13028-16E10$63.68 MSRP: $92.23You Save: $28.55 (31%)Ships in 1-3 Business Days

Nissan Maxima Belt-Timing

Part Number: 13028-12G00$63.68 MSRP: $92.23You Save: $28.55 (31%)Ships in 1-3 Business Days

Nissan Maxima Timing Belt

If you need any OEM Nissan Maxima Timing Belt, feel free to choose them out of our huge selection of genuine Nissan Maxima Timing Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Timing Belt Parts Questions & Experts Answers

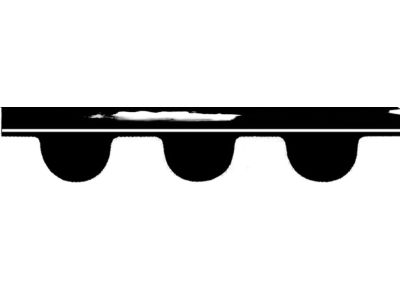

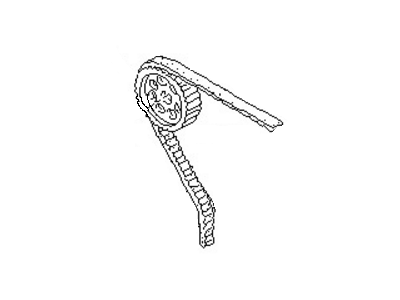

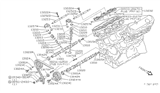

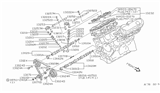

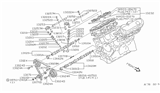

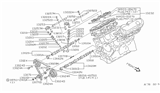

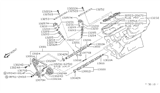

- Q: How do you remove and install the Timing Belt and Sprocket on Nissan Maxima with SOHC engine?A:To the above components, you should begin by disconnecting the cable from the negative terminal of battery and expel all the fluid in the cooling system. Release the lugs nuts of the right front wheel then jack up the front part of the car placing jack stands and engage the parking brake. Cinch the splash shield of the right front wheel and separate the inner fenderwell of the wheel. Then, all the drivebelts have to be detached along with the dipstick pan, and the cooling system should be drained, as well. Pull out the spark plugs and bring Number one piston at the top dead centre on the compression stroke. Remove the radiator hose and bypass hose from the thermostat housing also remove the water pump pulley. Removed the AC compressor idler pulley and bracket by loosening the three bolts and then removed the crankshaft pulley making sure the crankshaft is not turning. Check on the availability of the belts, in this case, a new factory belt should have three white markings of the alignment of the camshaft and crankshaft timing marks, while the aftermarket belts may differ. If the tensioner was removed, replace it into position and check and confirm that the spring was correctly positioned. Timing belt installation in advance is preparing by tightening the tensioner clockwise and partially tightening the lock nut. Replace the timing belt with the tightened marks of the belt facing the sprockets' corresponding marks while following a counterclockwise rotation without any looseness. Release air from the dead side of the belt, loosen the tensioner lock nut, and make the tensioner to take all the free play before tightening lock nut. Ensure all time marks are set properly, rotate the crankshaft clockwise and take the engine through two complete revolutions to bring no. 1 piston to TDC. Check the belt deflection approximately half way between the front and rear camshaft sprockets and that it is between 11-16mm. If the deflection is different from that specified, then one will just have to tweak with the tensioner. Check using a feeler gauge the tensioner pulley and tighten the tensioner locking nut with the tensioner in this position. After withdrawing the feeler gauge let the crankshaft rotate two times and bring the number one piston back to TDC and check the belt tension and align it again if required. Last but not the least; replace all parts that were disassembled and could not be cleaned.