×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

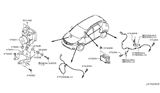

Genuine Nissan Murano ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 ABS Sensors found

Nissan Murano Sensor Assy-Antiskid,Front

Part Number: 47910-5AA0A$191.43 MSRP: $283.45You Save: $92.02 (33%)Ships in 1-3 Business Days

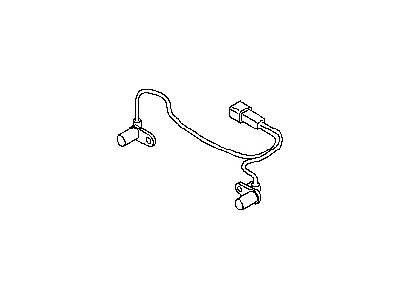

Nissan Murano Sensor Assembly-Anti SKID,Front LH

Part Number: 47911-CA000$141.04 MSRP: $250.60You Save: $109.56 (44%)Ships in 1 Business DayNissan Murano Sensor Assembly-Anti SKID,Front RH

Part Number: 47910-1AA0B$204.71 MSRP: $303.12You Save: $98.41 (33%)Ships in 1-3 Business DaysNissan Murano Sensor Assy-Antiskid,Rear

Part Number: 47901-5AA0A$357.98 MSRP: $546.38You Save: $188.40 (35%)Ships in 1-3 Business DaysNissan Murano Sensor Assy-Antiskid,Rear

Part Number: 47901-1AA0C$352.03 MSRP: $537.28You Save: $185.25 (35%)Ships in 1-3 Business DaysNissan Murano Sensor Assy-Antiskid,Front

Part Number: 47910-6SA1A$24.94 MSRP: $36.13You Save: $11.19 (31%)Ships in 1-3 Business DaysNissan Murano Sensor Assembly-Anti SKID,Front RH

Part Number: 47910-CA000$169.25 MSRP: $250.60You Save: $81.35 (33%)Ships in 1-3 Business DaysNissan Murano Sensor Assembly Anti Ski, Rear

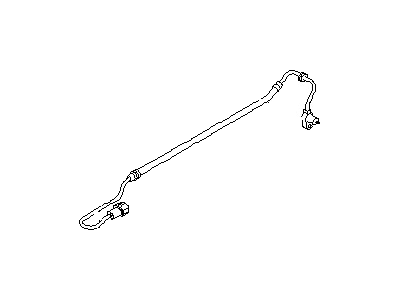

Part Number: 47900-1AD0B$333.62 MSRP: $509.18You Save: $175.56 (35%)Ships in 1-3 Business DaysNissan Murano Sensor Assy-Antiskid,Rear

Part Number: 47900-5AA0A$366.86 MSRP: $559.92You Save: $193.06 (35%)Ships in 1-3 Business DaysNissan Murano Sensor Assy-Antiskid,Rear

Part Number: 47900-1AA0C$355.47 MSRP: $542.55You Save: $187.08 (35%)Ships in 1-3 Business DaysNissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47900-CA00A$317.33 MSRP: $392.48You Save: $75.15 (20%)Ships in 1-3 Business DaysNissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47900-1AA0B$268.99 MSRP: $410.55You Save: $141.56 (35%)Ships in 1-3 Business DaysNissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47901-1AA0B$219.62 MSRP: $325.18You Save: $105.56 (33%)Ships in 1-3 Business DaysNissan Murano Harness Assembly-ANTISKID & Parking Brake, LH

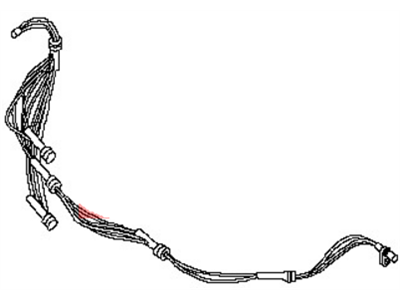

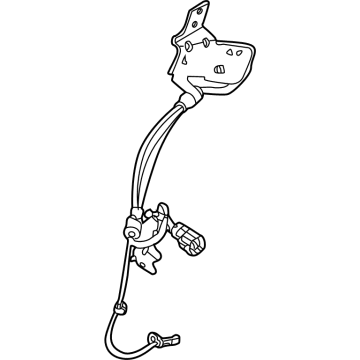

Part Number: 479A7-6TA1A$98.26 MSRP: $138.78You Save: $40.52 (30%)Ships in 1-3 Business DaysNissan Murano Sensor Assembly-Anti SKID,Front RH

Part Number: 47910-1AA0A$204.71 MSRP: $303.12You Save: $98.41 (33%)Ships in 1-3 Business DaysNissan Murano Harness Assembly-ANTISKID & Parking Brake, RH

Part Number: 479A6-6TA1A$98.26 MSRP: $138.78You Save: $40.52 (30%)Ships in 1-3 Business DaysNissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47900-CA000$317.33 MSRP: $392.48You Save: $75.15 (20%)Nissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47900-1AD0A$333.62 MSRP: $509.18You Save: $175.56 (35%)Ships in 1-3 Business DaysNissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47901-1AA0A$219.62 MSRP: $325.18You Save: $105.56 (33%)Nissan Murano Anti Skid Sensor Assembly Rear

Part Number: 47900-1AA0A$268.99 MSRP: $410.55You Save: $141.56 (35%)

| Page 1 of 2 |Next >

1-20 of 22 Results

Nissan Murano ABS Sensor

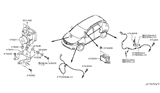

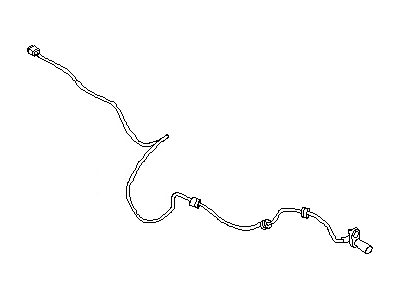

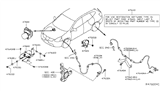

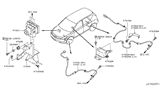

The Nissan Murano ABS Sensor is one of the critical elements applied in the car's anti-lock braking system (ABS) relating to its efficiency and safety across the Murano car models. Known for its high quality, the ABS Sensor is very important as it helps in maintaining the rotation of the wheels during braking and hence improve on the traction of the vehicle. Through the detection of the number of wheel rotations making voltage signals to the ABS control module in Nissan Murano, the vehicle stability in various road conditions is maintained through changes in hydraulic pressure. This sensor is suitable for a variety of generations of Nissan Murano, which, starting from the third generation, receive top-quality engineering and design. The ABS Sensor uses either a Hall type of effect or a gear with a magnetic coil resulting to the generation of wonderful signals depending on the fluctuating magnetic field. It could be slightly less accurate when the vehicle speed is low, however, its contribution to braking is invaluable. The Nissan Murano ABS Sensor has emerged as one of the highly popular ABS Sensor for car use owing to the fact that it is part of the car's security features to help the driver maneuver the car safely. As the present market revealed the Nissan Murano as a variant of mid-size crossover SUV with efficiency and safety features, the ABS Sensor enables a better satisfaction while driving it.

If you need any OEM Nissan Murano ABS Sensor, feel free to choose them out of our huge selection of genuine Nissan Murano ABS Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Murano ABS Sensor Parts Questions & Experts Answers

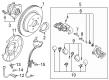

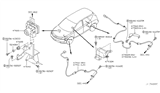

- Q: How to diagnose, remove, and install wheel speed sensors and ABS Control Module in the Anti-lock Brake System (ABS) on Nissan Murano?A:The Anti-lock Brake System (ABS) is designed to maintain vehicle steerability, directional stability, and optimum deceleration under severe braking conditions and on most road surfaces by monitoring the rotational speed of each wheel and controlling the Brake Line pressure to prevent wheel lock-up. The actuator assembly includes an electric hydraulic pump and solenoid valves for each wheel, providing hydraulic pressure to the braking system during ABS operation. Speed sensors at each wheel generate a sine wave current that is converted to a digital signal by the ABS Control Module, which processes information to control hydraulic line pressure and monitor for malfunctions. Upon starting the engine, the ABS warning light activates briefly, and a self-test occurs when the vehicle exceeds four mph; any detected issues will cause the light to remain on and store a diagnostic code. For wheel speed sensor removal, the wheel must be taken off after loosening the lug nuts, ensuring the ignition is off, and then the wiring is traced and disconnected before removing the sensor. Installation follows the reverse order, ensuring all components are securely fastened.

Related Nissan Murano Parts

Browse by Year

2025 ABS Sensor 2024 ABS Sensor 2023 ABS Sensor 2022 ABS Sensor 2021 ABS Sensor 2020 ABS Sensor 2019 ABS Sensor 2018 ABS Sensor 2017 ABS Sensor 2016 ABS Sensor 2015 ABS Sensor 2014 ABS Sensor 2013 ABS Sensor 2012 ABS Sensor 2011 ABS Sensor 2010 ABS Sensor 2009 ABS Sensor 2008 ABS Sensor 2007 ABS Sensor 2006 ABS Sensor 2005 ABS Sensor 2004 ABS Sensor 2003 ABS Sensor