×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Murano Coil Springs

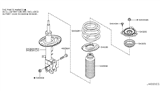

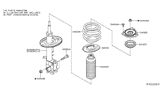

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Coil Springs found

Nissan Murano Front Spring

Part Number: 54010-5AA0C$180.04 MSRP: $254.30You Save: $74.26 (30%)Ships in 1-3 Business Days

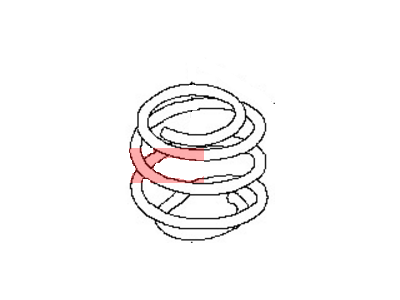

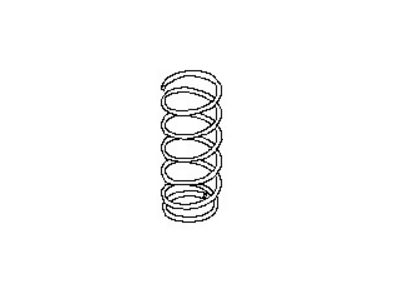

Nissan Murano Spring-Rear SUSPENSIONON

Part Number: 55020-5AA0C$101.15 MSRP: $142.87You Save: $41.72 (30%)Ships in 1-3 Business Days

Nissan Murano Front Spring

Part Number: 54010-1AA3B$232.60 MSRP: $328.40You Save: $95.80 (30%)Ships in 1-2 Business Days

Nissan Murano Rear Suspension Spring

Part Number: 55020-CA000$156.00 MSRP: $240.36You Save: $84.36 (36%)Ships in 1-3 Business Days

Nissan Murano Front Spring

Part Number: 54010-CA102$178.82 MSRP: $252.57You Save: $73.75 (30%)Ships in 1-3 Business Days

Nissan Murano Front Spring

Part Number: 54010-1AA0B$232.51 MSRP: $328.40You Save: $95.89 (30%)Ships in 1-3 Business Days

Nissan Murano Front Spring

Part Number: 54010-CA010$178.82 MSRP: $252.57You Save: $73.75 (30%)Ships in 1-3 Business Days

Nissan Murano Rear Suspension Spring

Part Number: 55020-1AA0A$291.05 MSRP: $411.08You Save: $120.03 (30%)Ships in 1-3 Business DaysNissan Murano Rear Suspension Spring

Part Number: 55020-5AA0D$111.58 MSRP: $157.60You Save: $46.02 (30%)Ships in 1-3 Business DaysNissan Murano Front Spring

Part Number: 54010-1GR0A$229.26 MSRP: $323.82You Save: $94.56 (30%)Ships in 1-3 Business DaysNissan Murano Front Spring

Part Number: 54010-CA004$109.54 MSRP: $164.60You Save: $55.06 (34%)Ships in 1-2 Business DaysNissan Murano Front Spring

Part Number: 54010-5AF0B$189.94 MSRP: $268.28You Save: $78.34 (30%)Ships in 1-3 Business DaysNissan Murano Rear Suspension Spring

Part Number: 55020-1GR0B$363.99 MSRP: $514.12You Save: $150.13 (30%)Ships in 1-3 Business DaysNissan Murano Front Spring

Part Number: 54010-1AA3A$232.51 MSRP: $328.40You Save: $95.89 (30%)Ships in 1-3 Business DaysNissan Murano Front Spring

Part Number: 54010-1AA0A$232.51 MSRP: $328.40You Save: $95.89 (30%)Ships in 1-3 Business DaysNissan Murano Rear Suspension Spring

Part Number: 55020-CA005$252.67 MSRP: $356.88You Save: $104.21 (30%)Ships in 1-3 Business DaysNissan Murano Rear Suspension Spring

Part Number: 55020-1AD0B$291.05 MSRP: $411.08You Save: $120.03 (30%)Ships in 1-3 Business DaysNissan Murano Rear Suspension Spring

Part Number: 55020-1AD0A$291.05 MSRP: $411.08You Save: $120.03 (30%)Nissan Murano Rear Suspension Spring

Part Number: 55020-1AA0B$291.05 MSRP: $411.08You Save: $120.03 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 26 Results

Nissan Murano Coil Springs

If you need any OEM Nissan Murano Coil Springs, feel free to choose them out of our huge selection of genuine Nissan Murano Coil Springs. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

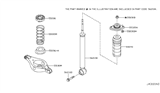

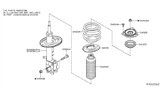

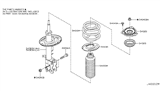

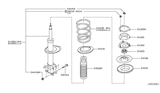

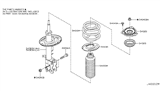

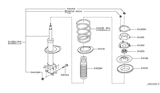

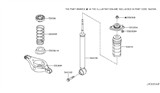

Nissan Murano Coil Springs Parts Questions & Experts Answers

- Q: What should you consider when struts or coil springs show signs of wear on Nissan Murano?A:If the struts or coil springs are leaking perhaps from the damper, show reduced damping potential or physical damage such as chipped or cracked then all options must be kept on the table as work begins. Some strut assemblies are pre-assembled with springs; in such cases these may be obtained on an exchange basis which can be a useful time saving combination. However, it is recommended to check for the prices and the availability of the parts before dismantling the vehicle irrespective of the chosen strategy. First, disconnect the strut and spring assembly, then clamp it in a wooden vise, pulling the assembly very tightly but not too tightly. In compliance with the instructions handed by the tool manufacturer, fit a spring compressor to ease the pressure on the upper spring seat; this is evidenced by some vibrations of the spring. Subsequently, take off the piston rod nut and the upper suspension support; to test the bearing should turn smooth and the rubber should be checked for signs of wear. Raise the spring seat as well as upper insulator off the piston rod, examine the rubber spring seat that was beneath for damages. After that, slowly take the compressed spring out of the assembly and unlock the dust boot on the piston rod, and look for the signs of wear on the lower insulator if necessary, replace it. For reassembly, if replacing the lower insulator, install it to the correct position and contract the damper rod to install the dust boot. Position the coil spring on lower insulator such a way that one end of the spring is in the right place to fit in. Place the upper insulator and spring seat in the same way noting the outward mark or arrows and fix the dust seal and suspension support on the piston rod. Last of all tighten the nut to the correct torque and then replace the strut/shock absorber and coil spring.

Related Nissan Murano Parts

Browse by Year

2025 Coil Springs 2024 Coil Springs 2023 Coil Springs 2022 Coil Springs 2021 Coil Springs 2020 Coil Springs 2019 Coil Springs 2018 Coil Springs 2017 Coil Springs 2016 Coil Springs 2015 Coil Springs 2014 Coil Springs 2013 Coil Springs 2012 Coil Springs 2011 Coil Springs 2010 Coil Springs 2009 Coil Springs 2008 Coil Springs 2007 Coil Springs 2006 Coil Springs 2005 Coil Springs 2004 Coil Springs 2003 Coil Springs