×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Murano CV Boot

Axle Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 CV Boots found

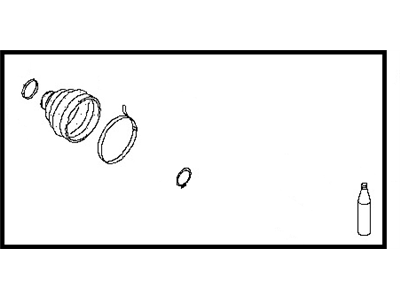

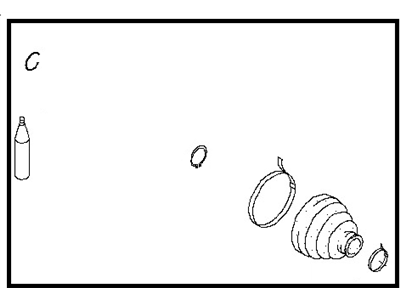

Nissan Murano Dust Boot Repair Kit Inner

Part Number: C9741-3JA0A$45.97 MSRP: $63.37You Save: $17.40 (28%)Ships in 1-3 Business Days

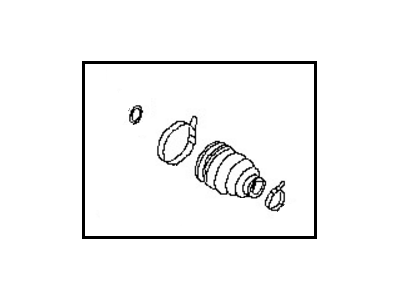

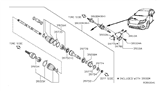

Nissan Murano Boot Kit

Part Number: C9241-EA00J$84.55 MSRP: $119.42You Save: $34.87 (30%)Ships in 1-3 Business Days

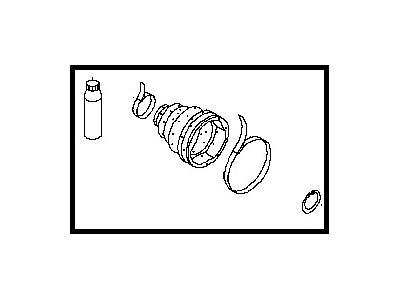

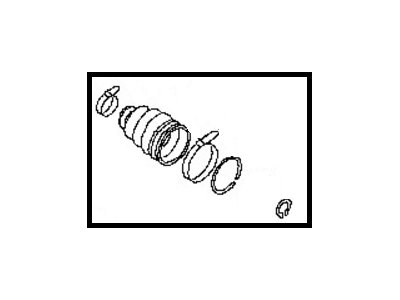

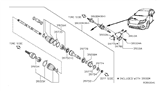

Nissan Murano Repair Kit-Dust Boot,Outer

Part Number: 39241-2U625$76.35 MSRP: $107.83You Save: $31.48 (30%)Ships in 1-2 Business Days

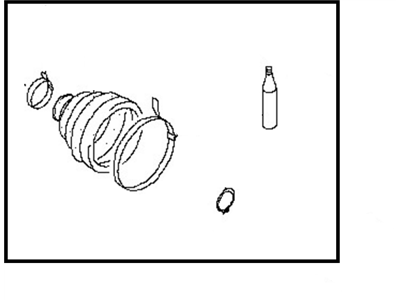

Nissan Murano Repair Kit-Dust Boot,Outer

Part Number: 39241-CA025$64.61 MSRP: $91.25You Save: $26.64 (30%)Ships in 1-2 Business Days

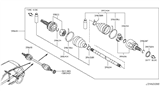

Nissan Murano Repair Kit-Dust B00T,Inner

Part Number: C9741-1AA0A$77.43 MSRP: $109.37You Save: $31.94 (30%)Ships in 1-3 Business Days

Nissan Murano Repair Kit-Dust Boot,Outer

Part Number: C924A-1AA0A$86.92 MSRP: $122.77You Save: $35.85 (30%)Ships in 1-3 Business Days

Nissan Murano Repair Kit-Dust Boot,Rear Drive Shaft

Part Number: C9741-2U60A$68.57 MSRP: $96.85You Save: $28.28 (30%)Ships in 1-3 Business Days

Nissan Murano Repair Kit-Dust Boot,Rear Drive Shaft

Part Number: C9741-JD60J$68.57 MSRP: $96.85You Save: $28.28 (30%)Ships in 1-3 Business Days

Nissan Murano Dust Boot Repair Kit Inner

Part Number: C9741-1JA0A$77.43 MSRP: $109.37You Save: $31.94 (30%)Ships in 1-3 Business Days

Nissan Murano Repair Kit-Dust B00T,Inner

Part Number: C9G41-1AA0A$77.43 MSRP: $109.37You Save: $31.94 (30%)Ships in 1-3 Business Days

Nissan Murano Repair Kit-Dust B00T,Inner

Part Number: C9741-CC20A$44.47 MSRP: $61.30You Save: $16.83 (28%)Ships in 1-2 Business DaysNissan Murano Dust Boot Repair Kit Inner

Part Number: C9GDA-2U60H$68.57 MSRP: $96.85You Save: $28.28 (30%)Ships in 1-3 Business DaysNissan Murano Repair Kit Dust Boot Outer

Part Number: C9BDA-2U62H$76.35 MSRP: $107.83You Save: $31.48 (30%)Ships in 1-3 Business DaysNissan Murano Dust Boot Kit-Repair,Inner

Part Number: C9741-JG04B$56.90 MSRP: $78.43You Save: $21.53 (28%)Ships in 1-3 Business DaysNissan Murano Dust Boot Repair Kit Inner

Part Number: 39741-17V28$60.68 MSRP: $85.70You Save: $25.02 (30%)Ships in 1-3 Business DaysNissan Murano Repair Kit - Dust Boot, Rear Drive Shaft

Part Number: C9741-6SA1A$65.41 MSRP: $92.38You Save: $26.97 (30%)Ships in 1-3 Business DaysNissan Murano Dust Boot Repair Kit Inner

Part Number: C974A-1JA0A$77.43 MSRP: $109.37You Save: $31.94 (30%)Ships in 1-3 Business DaysNissan Murano Repair Kit - Dust Boot, Rear Drive Shaft

Part Number: 39741-2U626$50.38 MSRP: $69.45You Save: $19.07 (28%)Ships in 1-3 Business DaysNissan Murano Repair Kit-Dust Boot,Outer

Part Number: 39241-2U627$76.35 MSRP: $107.83You Save: $31.48 (30%)Ships in 1-3 Business DaysNissan Murano Repair Kit-Dust Boot,Outer

Part Number: C9241-1AA0A$77.20 MSRP: $109.03You Save: $31.83 (30%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

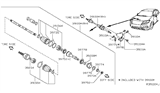

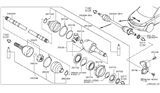

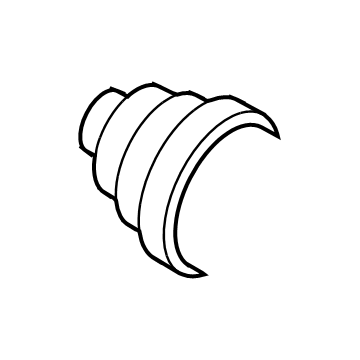

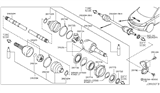

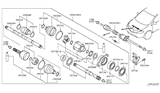

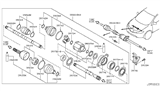

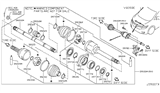

Nissan Murano CV Boot

CV Boot is one of the vital parts that help a lot in providing better durability and other features to Nissan Murano. This flexible rubber or plastic component shields the sleeves, or constant velocity (CV) joints that are important in transmitting the power from the transaxle to wheels. Due to the ability to retain the required lubricant and to avoid jamming of details, the CV Boot provides the correct function of the CV joints, which are aimed at traversing diverse roads. Different types of CV joints applied in Nissan Murano differ with the models, the outer ends of Nissan Murano uses the rzeppa joint while the internal ends employ tripod or double offset joints to properly maintain the efficiency and security of the vehicle. Periodic checking is important for the CV Boot because even minor damage like cracks and tears has a dangerous effect to the CV joints and therefore affects the life span of the car. The CV Boot fits different models of Murano hence can be applied by Murano owners who want to maintain their cars. Other noticeable qualities of the vehicle include its durability and capacity to as well as optimize it in extreme harsh climates so that the Nissan Murano maintains and further guarantees a seamless and comfortable drive for the owners. Being an important maintenance area owing to endurance and reliability the CV Boot reflects the quality that Nissan Murano holds in the automobile industry.

If you need any OEM Nissan Murano CV Boot, feel free to choose them out of our huge selection of genuine Nissan Murano CV Boot. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

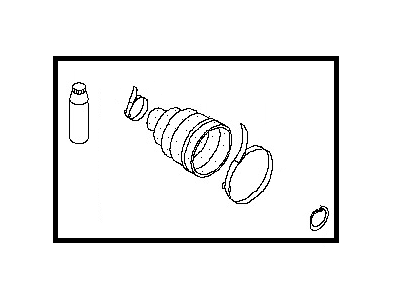

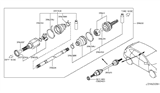

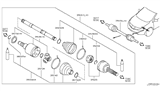

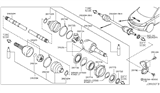

Nissan Murano CV Boot Parts Questions & Experts Answers

- Q: How to replace the CV Boot on Nissan Murano?A:In case of overhauling of CV joints, normally needed because of the torn boots, all alternatives should be considered as rebuilt drive axles can be purchased on an exchange basis which would certainly prove more convenient. While some of these vehicles may be easy to disassemble others may prove difficult thus the need to check on the cost of the spare parts and their availability. When pulling apart the inner CV joint, one needs to take out the driveaxle, and the boot clamps, where the boot has to be pulled back, the retaining ring must be removed, and finally the joint housing slides off. Stake the tripod and axleshaft for reassembly, then cautiously remove the snap-ring from the axleshaft and knock out the tripod joint from the driveaxle using a hammer and a brass punch, in a way as not to mar the wearing surfaces. If a rubber dynamic balancer is mounted then put a mark on the location where it is to be removed. Shake all of the components with solvent for inspection of wear and tear. To reassemble the clamps and the boot to the axleshaft use a tape to cover the splines to avoid damaging the boot then insert the tripod and snap-ring and finally apply grease that should cover both the housing and the retaining ring. Change the length of the joint, balance the pressure within the boot, and fasten the boot clamps before using another new snap-ring, and the driveaxle. In the front outer CV joint, unscrew and unbolt the driveaxle and the boot clamps before pulling the outer CV joint with a slide hammer with bearings checked and stuffing the joint with grease. Finally, fit in the boot and snap ring, and locate the CV joint on the driveaxle before sliding it on gently to to engage well. For the rear outer CV joint, first the driveaxle should be un bolted and then put into a vise then remove the boot clamp and then using a slide hammer the CV joint can be pulled off. Remove the old grease, put some tapes on the splines and slip a new boot on, then install a new ring and shrink sleeved CV joint over the axel. Put fresh grease, slam the boot, modify its length, make the pressure on both sides same and then bolt the boot finally fixing the driveaxle assembly.