×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

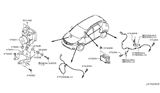

17 ABS Sensors found

Nissan Quest Sensor Assembly-Anti SKID,Front RH

Part Number: 47910-1JA0B$189.95 MSRP: $281.25You Save: $91.30 (33%)Ships in 1-3 Business Days

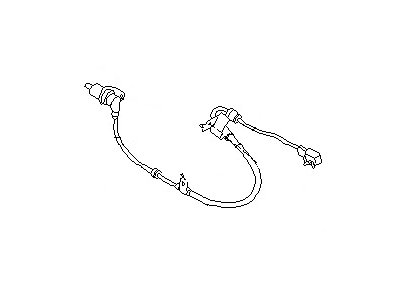

Nissan Quest Sensor Assembly-Anti SKID,Front RH

Part Number: 47910-CK000$130.87 MSRP: $189.53You Save: $58.66 (31%)Ships in 1-3 Business Days

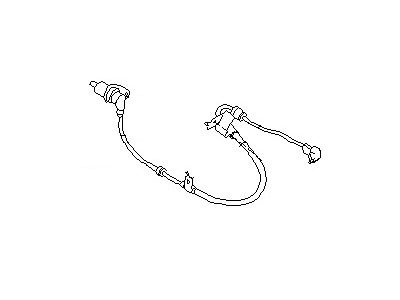

Nissan Quest Sensor Assembly-Anti SKID,Front LH

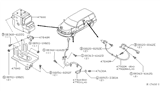

Part Number: 47911-CK000$109.06 MSRP: $189.53You Save: $80.47 (43%)Ships in 1-2 Business DaysNissan Quest Sensor Assembly Anti Ski, Rear

Part Number: 47900-1AD0B$333.62 MSRP: $509.18You Save: $175.56 (35%)Ships in 1-3 Business DaysNissan Quest Anti Skid Sensor Assembly Rear

Part Number: 47901-CK000$328.79 MSRP: $501.82You Save: $173.03 (35%)Ships in 1-3 Business DaysNissan Quest Sensor Assembly-Anti SKID,Front L

Part Number: 47911-ZM00A$140.36 MSRP: $207.83You Save: $67.47 (33%)Ships in 1-3 Business Days

Nissan Quest ABS Sensor

If you need any OEM Nissan Quest ABS Sensor, feel free to choose them out of our huge selection of genuine Nissan Quest ABS Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

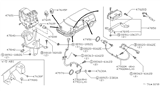

Nissan Quest ABS Sensor Parts Questions & Experts Answers

- Q: What is the purpose and functionality of the ABS Control Module, ABS Sensor and Anti-lock Brake System (ABS) on Nissan Quest?A:The Anti-lock Brake System (ABS) is supposed to help in maintaining vehicle steerability, the direction in which a car is moving, and the slowest rate of speed at which it loses that direction through severe braking and over rough roads through continuous measurement of the speed of each wheel and regulating brake line pressure to avoid lock up. This type includes the hydraulic actuator, the front and rear wheel velocity sensors, the ABS control unit, the motor of relay and the solenoid relay. There is the electric hydraulic pump and three solenoid operated valves in the actuator assembly to supply hydraulic pressure to the brake system and control the boost pressure of brake lines respectively during the operation. Each wheel has a speed sensor in which sine wave current is created when the toothed sensor rotors turn; this signal is converted digitally by the ABS control unit to determine wheel speed. The control unit is situated near the center console behind it and it works by receiving data from the sensors regarding pressure control and checking for anomalous behavior; this unit turns on the ABS light when the engine is switched on and conducts a preliminary diagnostic test when the vehicle's speed exceeds 4mph. This message must therefore be given attention and while identifying what is wrong might be cumbersome, a diagnostic trouble code can be retrieved by shorting a terminal and observing the patterns of the ABS light. These simple tests range from checking the brake fluid levels, electrical connections, fuses, as well as the brake parts. If the above said elements are found satisfactory then efforts can be made to clear the stored trouble codes and if the problem still remains then it is advised to consult a professional.

Related Nissan Quest Parts

Browse by Year

2017 ABS Sensor 2016 ABS Sensor 2015 ABS Sensor 2014 ABS Sensor 2013 ABS Sensor 2012 ABS Sensor 2011 ABS Sensor 2010 ABS Sensor 2009 ABS Sensor 2008 ABS Sensor 2007 ABS Sensor 2006 ABS Sensor 2005 ABS Sensor 2004 ABS Sensor 2003 ABS Sensor 2002 ABS Sensor 2001 ABS Sensor 2000 ABS Sensor 1999 ABS Sensor 1998 ABS Sensor 1997 ABS Sensor 1996 ABS Sensor 1995 ABS Sensor 1994 ABS Sensor 1993 ABS Sensor