×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest Automatic Transmission Filter

AT Filter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Automatic Transmission Filters found

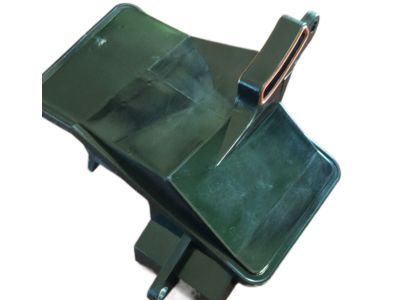

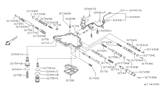

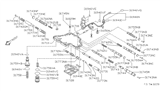

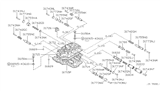

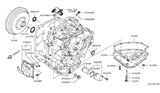

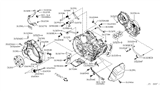

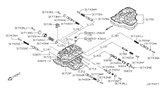

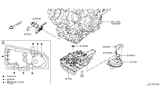

Nissan Quest Filter Assembly-Oil Governor

Part Number: 31726-28X0A$18.08 MSRP: $25.53You Save: $7.45 (30%)Ships in 1-2 Business Days

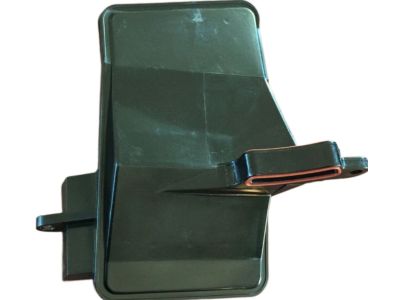

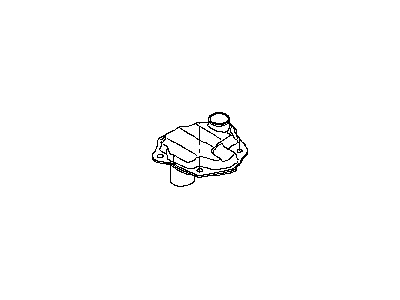

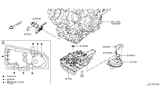

Nissan Quest Oil Strainer Assembly

Part Number: 31728-29X0D$47.48 MSRP: $67.07You Save: $19.59 (30%)Ships in 1-2 Business Days

Nissan Quest Oil Filter Assembly

Part Number: 31726-1XE0A$45.77 MSRP: $66.28You Save: $20.51 (31%)Ships in 1-3 Business Days

Nissan Quest Oil Strainer Assembly

Part Number: 31728-80X04$28.98 MSRP: $39.95You Save: $10.97 (28%)Ships in 1-3 Business Days

Nissan Quest Oil Strainer Assembly

Part Number: 31728-8Y000$41.14 MSRP: $56.72You Save: $15.58 (28%)Ships in 1-3 Business Days

Nissan Quest Oil Filter Assembly

Part Number: 31726-41X00$15.55 MSRP: $22.52You Save: $6.97 (31%)Ships in 1-3 Business Days

Nissan Quest Oil Strainer Assembly

Part Number: 31728-85X0A$77.81 MSRP: $109.90You Save: $32.09 (30%)Ships in 1-3 Business DaysNissan Quest Oil Strainer

Part Number: 31728-8Y010$53.67 MSRP: $73.98You Save: $20.31 (28%)Ships in 1-3 Business DaysNissan Quest Automatic Transmission Filter

Part Number: 31728-85X01$77.81 MSRP: $109.90You Save: $32.09 (30%)Ships in 1-3 Business DaysNissan Quest Oil Strainer Assembly

Part Number: 31728-80L01$28.98 MSRP: $39.95You Save: $10.97 (28%)Ships in 1-3 Business DaysNissan Quest Oil Strainer Assembly

Part Number: 31728-80X03$28.98 MSRP: $39.95You Save: $10.97 (28%)Ships in 1-3 Business Days

Nissan Quest Automatic Transmission Filter

If you need any OEM Nissan Quest Automatic Transmission Filter, feel free to choose them out of our huge selection of genuine Nissan Quest Automatic Transmission Filter. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

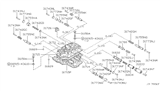

Nissan Quest Automatic Transmission Filter Parts Questions & Experts Answers

- Q: How to drain and replace transaxle fluid and Automatic Transmission Filter on Nissan Quest?A:At the specified time intervals, the transaxle fluid should be drained and replaced. Since the fluid will remain hot long after driving, perform this procedure only after everything has cooled down completely. Before beginning work, purchase the specified transaxle fluid and a new filter. Other tools necessary for this job include jackstands to support the vehicle in a raised position, a drain pan capable of holding several quarts, newspapers and clean rags. Raise the vehicle and support it securely on jackstands. With a drain pan in place, remove the drain plug, allow the fluid to drain fully, then remove the pan bolts. Note: Measure the amount of fluid drained and record it; when refilling the transaxle, start with that amount. Carefully pry the transaxle pan loose with a screwdriver and detach the pan and gasket. Carefully clean the gasket surface of the transaxle to remove all traces of the old gasket and sealant. Drain the remaining fluid from the transaxle pan, clean the pan with solvent and dry it with compressed air or a clean rag. Be careful not to lose the magnets. Remove the bolts and detach the filter. Install the new filter. Make sure the gasket surface on the transaxle pan is clean, then install the magnet and a new gasket. Put the pan in place against the transaxle and install the bolts. Working around the pan tighten each bolt a little at a time until the final torque figure. Don't overtighten the bolts! Lower the vehicle and add the same amount of new automatic transmission fluid that was measured through the filler tube. With the shift lever in Park and the parking brake set, run the engine at a fast idle, but don't race it. Move the shift lever through each gear and back to Park. Check the fluid level and add some, as necessary, to bring it to the appropriate level. Caution: Add fluid a little at a time to avoid overfilling. Check under the vehicle for leaks during the first few trips.

Related Nissan Quest Parts

Browse by Year

2017 Automatic Transmission Filter 2016 Automatic Transmission Filter 2015 Automatic Transmission Filter 2014 Automatic Transmission Filter 2013 Automatic Transmission Filter 2012 Automatic Transmission Filter 2011 Automatic Transmission Filter 2010 Automatic Transmission Filter 2009 Automatic Transmission Filter 2008 Automatic Transmission Filter 2007 Automatic Transmission Filter 2006 Automatic Transmission Filter 2005 Automatic Transmission Filter 2004 Automatic Transmission Filter 2003 Automatic Transmission Filter 2002 Automatic Transmission Filter 2001 Automatic Transmission Filter 2000 Automatic Transmission Filter 1999 Automatic Transmission Filter 1998 Automatic Transmission Filter 1997 Automatic Transmission Filter 1996 Automatic Transmission Filter 1995 Automatic Transmission Filter 1994 Automatic Transmission Filter 1993 Automatic Transmission Filter