×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

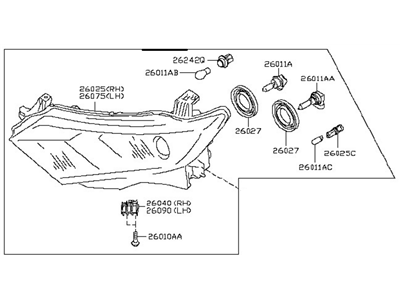

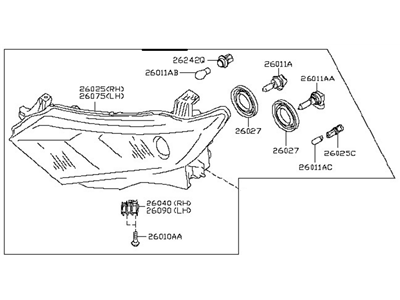

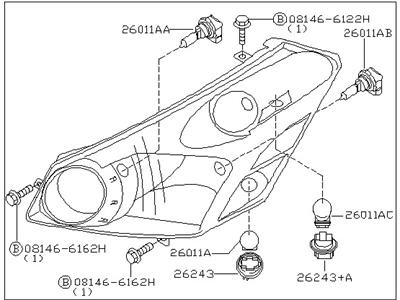

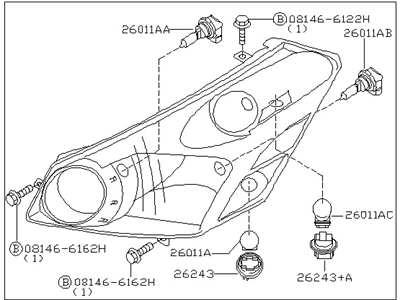

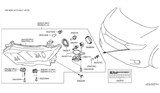

Genuine Nissan Quest Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

48 Headlights found

Nissan Quest Driver Side Headlight Assembly

Part Number: 26060-1JA3A$798.26 MSRP: $1205.87You Save: $407.61 (34%)Ships in 1-3 Business Days

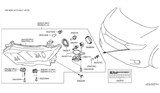

Nissan Quest Passenger Side Headlight Assembly

Part Number: 26010-1JR1A$932.45 MSRP: $1436.75You Save: $504.30 (36%)Ships in 1-3 Business Days

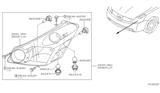

Nissan Quest Driver Side Headlight Assembly

Part Number: 26060-5Z026$248.92 MSRP: $383.55You Save: $134.63 (36%)Ships in 1-3 Business Days

Nissan Quest Passenger Side Headlight Assembly

Part Number: 26010-5Z026$248.92 MSRP: $383.55You Save: $134.63 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlight Assembly

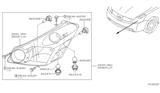

Part Number: 26060-1JR0A$307.53 MSRP: $473.85You Save: $166.32 (36%)Ships in 1-3 Business DaysNissan Quest Headlamp Assembly-Passenger Side

Part Number: 26010-1JR0A$307.53 MSRP: $473.85You Save: $166.32 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlamp Housing Assembly

Part Number: 26075-1JA0C$513.35 MSRP: $790.98You Save: $277.63 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlight Assembly

Part Number: 26060-1JA0A$304.46 MSRP: $469.13You Save: $164.67 (36%)Ships in 1-3 Business DaysNissan Quest Passenger Side Headlamp Housing Assembly

Part Number: 26025-1JA0C$503.55 MSRP: $775.89You Save: $272.34 (36%)Ships in 1-3 Business DaysNissan Quest Passenger Side Headlight Assembly

Part Number: 26010-1JA1A$932.45 MSRP: $1436.75You Save: $504.30 (36%)Ships in 1-2 Business DaysNissan Quest Passenger Side Headlight Assembly

Part Number: 26010-1JA0A$304.46 MSRP: $469.13You Save: $164.67 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlamp Housing Assembly

Part Number: 26075-1JA0A$306.04 MSRP: $471.56You Save: $165.52 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlamp Housing Assembly

Part Number: 26076-1JA1A$758.54 MSRP: $1168.78You Save: $410.24 (36%)Ships in 1-3 Business DaysNissan Quest Passenger Side Headlamp Housing Assembly

Part Number: 26025-1JA3A$1345.33 MSRP: $2072.93You Save: $727.60 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlamp Housing Assembly

Part Number: 26075-1JA3A$1426.64 MSRP: $2198.22You Save: $771.58 (36%)Ships in 1-3 Business DaysNissan Quest Passenger Side Headlamp Housing Assembly

Part Number: 26025-1JA0A$342.71 MSRP: $514.96You Save: $172.25 (34%)Ships in 1-2 Business DaysNissan Quest Driver Side Headlight Assembly

Part Number: 26060-1JA1A$798.26 MSRP: $1205.87You Save: $407.61 (34%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlight Assembly

Part Number: 26060-1JA0C$307.53 MSRP: $473.85You Save: $166.32 (36%)Ships in 1-2 Business DaysNissan Quest Driver Side Headlight Assembly

Part Number: 26060-5Z001$248.92 MSRP: $383.55You Save: $134.63 (36%)Ships in 1-3 Business DaysNissan Quest Driver Side Headlight Assembly

Part Number: 26060-1JR1A$798.26 MSRP: $1205.87You Save: $407.61 (34%)Ships in 1-3 Business Days

| Page 1 of 3 |Next >

1-20 of 48 Results

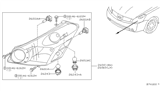

Nissan Quest Headlight

If you need any OEM Nissan Quest Headlight, feel free to choose them out of our huge selection of genuine Nissan Quest Headlight. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to avoid blinding oncoming drivers and ensure optimal visibility on the road on Nissan Quest?A:Often, the aim of the headlights is improper; this can cause blind spots for drivers approaching a car from the front or behind, or hinder visibility on the road. The aim should be checked at least once a year or anytime that a new headlight has been installed or anytime the front-end body work has been done. The adjustment screw is located at the top of each assembly for each headlight; there are nuts for adjusting the vertical axis and another for the horizontal axis. First of all, place the vertical piece of masking tape on the wall parallel to the car centerline and parallel to the centerlines of the two headlights, and, in addition, place one horizontal line of tape for further convenience. The position of the vehicle should be 25 feet away from the fire wall, having a stable position, with a half tank of gasoline, and free from heavy load. For low beam adjustment-move the high-intensity zone 2 inches below the horizontal line-2 inches right from the vertical line using the top screw to raise the beam and the side screw for the left/right adjustment. Thus, the high intensity zone should be adjusted to be below the straight horizontal when high beams are on, still noting that low beams are far more significant in considerations of safety. This means that service providers should align the headlights as soon as possible preferably by a professional.

Related Nissan Quest Parts

Browse by Year

2017 Headlight 2016 Headlight 2015 Headlight 2014 Headlight 2013 Headlight 2012 Headlight 2011 Headlight 2010 Headlight 2009 Headlight 2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight