×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Quest Vapor Canister

Fuel Vapor Canister- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Vapor Canisters found

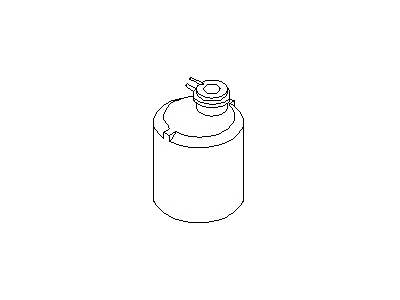

Nissan Quest Evaporative Emission Canister

Part Number: 14950-7Y00A$277.43 MSRP: $391.85You Save: $114.42 (30%)Ships in 1-3 Business DaysNissan Quest Emission Canister Assembly

Part Number: 14950-1JA0A$282.95 MSRP: $399.65You Save: $116.70 (30%)Ships in 1-3 Business DaysNissan Quest CANISTER Assembly-EVAPORATION

Part Number: 14950-7Y000$277.43 MSRP: $391.85You Save: $114.42 (30%)Nissan Quest CANISTER Assembly-EVAPORATION

Part Number: 14950-0B000$87.23 MSRP: $123.20You Save: $35.97 (30%)

Nissan Quest Vapor Canister

If you need any OEM Nissan Quest Vapor Canister, feel free to choose them out of our huge selection of genuine Nissan Quest Vapor Canister. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Quest Vapor Canister Parts Questions & Experts Answers

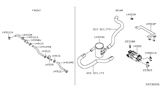

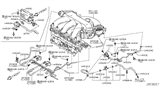

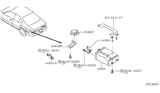

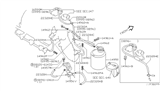

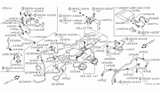

- Q: How to inspect and replace the canister on Nissan Quest?A:Finally, the fuel evaporation control system known as the EVAP system, takes in fuel vapor and injects them into engines where they form part of the air-feed mixture during engine operation. This is a charcoal chamber that is mounted on fuel tank, ported vacuum and intake manifold vacuum coupled with purge control valve that is installed in the canister which is filled with charcoal. Starting from the 1996 models, this valve is controlled either by a EGR/ EVAP canister control solenoid depending on the year and model; California models from 1998 have a separate EVAP control solenoid mounted on the throttle body bracket. The fuel vapors are accumulated in the said canister when the engine is not running and released during execution to help in the burning of fuel. Problems of idle and stalling or poor driveability may be caused by a faulty solenoid valve or a bad canister or defective hose. Loosing fuel or smell like fuel may be as a result of fuel line leakage, defective check valve or vapor line. The hose should be checked for formation of kinks and leakage and the canister for formation of any cracks. If fuel leaks from the canister, then it has to be changed, in addition to examining the hoses as well. The purge control valve must be tested through creation of vacuum to check if it can hold the vacuum for a least 20 seconds if it does not meet this threshold then it will have to be replaced. For canister replacement the vacuum lines have to be identified and disconnected, and the mounting bolts then have to be removed to pull out the canister assembly; to replace it, the process is done the reverse of what is described above.

Related Nissan Quest Parts

Browse by Year

2017 Vapor Canister 2016 Vapor Canister 2015 Vapor Canister 2014 Vapor Canister 2013 Vapor Canister 2012 Vapor Canister 2011 Vapor Canister 2010 Vapor Canister 2009 Vapor Canister 2008 Vapor Canister 2007 Vapor Canister 2006 Vapor Canister 2005 Vapor Canister 2004 Vapor Canister 2003 Vapor Canister 2002 Vapor Canister 2001 Vapor Canister 2000 Vapor Canister 1999 Vapor Canister 1998 Vapor Canister 1997 Vapor Canister 1996 Vapor Canister 1995 Vapor Canister 1994 Vapor Canister 1993 Vapor Canister