×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Rogue ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 ABS Sensors found

Nissan Rogue Sensor Assembly-Anti SKID, Front

Part Number: 47910-4BA0A$182.13 MSRP: $269.68You Save: $87.55 (33%)Ships in 1-3 Business Days

Nissan Rogue Sensor Assembly Anti Ski, Rear

Part Number: 47900-4BA0A$231.04 MSRP: $342.10You Save: $111.06 (33%)Ships in 1-3 Business Days

Nissan Rogue Sensor Assembly Anti Ski, Rear

Part Number: 47900-4BF0A$242.75 MSRP: $359.43You Save: $116.68 (33%)Ships in 1-3 Business Days

Nissan Rogue Sensor Assy-Antiskid,Front

Part Number: 47910-4CE0A$182.56 MSRP: $270.32You Save: $87.76 (33%)Ships in 1-3 Business Days

Nissan Rogue Sensor Assembly Anti Ski, Rear

Part Number: 47900-1DC1A$200.64 MSRP: $297.08You Save: $96.44 (33%)Ships in 1-2 Business Days

Nissan Rogue Sensor Assembly-Anti SKID,Front

Part Number: 47910-JG000$181.01 MSRP: $268.02You Save: $87.01 (33%)Ships in 1-2 Business DaysNissan Rogue Sensor Assy-Antiskid,Front

Part Number: 47910-4CB0A$199.09 MSRP: $294.80You Save: $95.71 (33%)Ships in 1-3 Business DaysNissan Rogue Sensor Assy-Antiskid,Rear

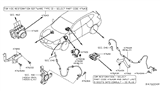

Part Number: 47900-4CB4A$324.73 MSRP: $495.63You Save: $170.90 (35%)Ships in 1-3 Business DaysNissan Rogue Harness Assembly-ANTISKID & Parking Brake, RH

Part Number: 479A6-6RA0A$155.68 MSRP: $219.88You Save: $64.20 (30%)Ships in 1-3 Business DaysNissan Rogue Sensor Assy-Antiskid,Rear

Part Number: 47900-4CB2A$355.72 MSRP: $542.92You Save: $187.20 (35%)Ships in 1-3 Business DaysNissan Rogue Sensor Assy-Antiskid,Front

Part Number: 47910-6RR0A$215.46 MSRP: $319.03You Save: $103.57 (33%)Ships in 1-3 Business DaysNissan Rogue Harness Assembly-ANTISKID & Parking Brake, LH

Part Number: 479A7-6RA0A$150.93 MSRP: $213.18You Save: $62.25 (30%)Ships in 1-3 Business DaysNissan Rogue Sensor Assembly-Anti SKID, Front

Part Number: 47910-1DA1A$181.01 MSRP: $268.02You Save: $87.01 (33%)Ships in 1-2 Business DaysNissan Rogue Sensor Assy-Antiskid,Rear

Part Number: 47900-4CE4A$243.59 MSRP: $360.68You Save: $117.09 (33%)Ships in 1-3 Business DaysNissan Rogue Sensor Assembly Anti Ski, Rear

Part Number: 47900-1DA1A$202.83 MSRP: $300.33You Save: $97.50 (33%)Ships in 1-3 Business DaysNissan Rogue Sensor Assy-Antiskid,Front

Part Number: 47910-6RA0A$212.87 MSRP: $315.20You Save: $102.33 (33%)Ships in 1-3 Business DaysNissan Rogue Sensor Assy-Antiskid,Rear

Part Number: 47900-4CE2A$224.94 MSRP: $333.07You Save: $108.13 (33%)Ships in 1-3 Business DaysNissan Rogue Anti Skid Sensor Assembly Rear

Part Number: 47900-JG200$200.64 MSRP: $297.08You Save: $96.44 (33%)Nissan Rogue Anti Skid Sensor Assembly Rear

Part Number: 47900-JG000$202.83 MSRP: $300.33You Save: $97.50 (33%)

Nissan Rogue ABS Sensor

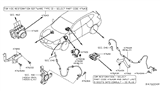

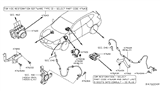

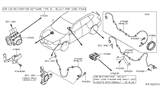

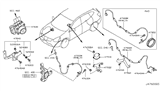

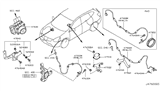

The ABS Sensor in the Nissan Rogue's is key in the anti-lock braking system especially in watching the wheel rotation to avoid locking up of the wheels in the process of braking. It feeds important information to the vehicle's computer, which tells it under what conditions it should put the ABS to work with loss of traction. The sensor can operate on a magnet and hall effect sensor or toothed wheel with an electromagnetic coil, and it produces voltage signals from the magnetic field changes as it rotates the wheel. In years gone by, several styles of Nissan ABS Sensor may have been applied but all have the same basic purpose. One of the limitations of these Rogue ABS Sensor is that the accuracy decreases at low speeds which may compromise the propriety of the data sent to the ABS controller. However, the Nissan Rogue ABS Sensor is still of great importance for increasing the vehicle safety as it facilitates an effective braking on different conditions.

If you need any OEM Nissan Rogue ABS Sensor, feel free to choose them out of our huge selection of genuine Nissan Rogue ABS Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Rogue ABS Sensor Parts Questions & Experts Answers

- Q: What is the purpose and functionality of the ABS Control Module, ABS Sensor and Anti-lock Brake System on Nissan Rogue?A:ABS or Anti-lock Brake System is a mechanism tool that is responsible for the maintainability of vehicle steerability, directional stability, and optimum slowing down on severe braking and on various road surfaces without allowing each wheel fully lock; this is attained by monitoring the rotational speed of each wheel and controlling the brake pressure line. The actuator assembly is found at the right rear corner of the engine compartment While the electric hydraulic pump acts as the main supplier of hydraulic pressure to the brake system during the ABS operation, the solenoids valves for each wheel are used in cases were specific wheel pressure needs to be addressed. Sine wave current is produced from the wheel sensors when the rotors of the sensor turn and the ABS control units convert the analog signal into a digital form to assess the wheel's velocity. The major components of the ABS control unit-which is housed in the actuator-use signals from the wheel speed sensors to modulate hydraulic pressure for the wheel brakes to avoid further lock up while at the same time checking for system failure. At engine start up the ABS light comes on as a normal procedure but should turn off in about one second the self check is done when the vehicle reaches a speed of more than 4mph and at this time a sort of mechanical noise may be heard. If there is an error, the warning light on the dashboard stays on and a code that corresponds to the problem is saved in the control unit.