×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

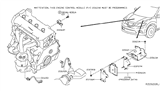

Genuine Nissan Rogue Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Oxygen Sensors found

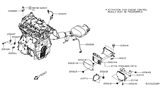

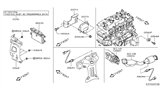

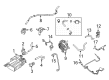

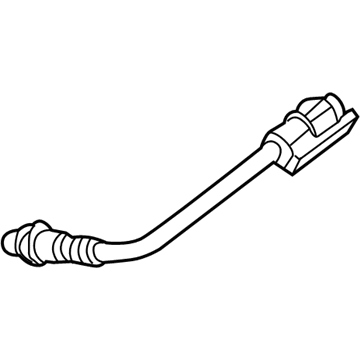

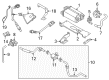

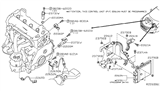

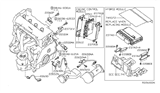

Nissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-9HP0A$244.69 MSRP: $362.32You Save: $117.63 (33%)Ships in 1-2 Business Days

Nissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-1AA0A$219.46 MSRP: $324.97You Save: $105.51 (33%)Ships in 1-2 Business Days

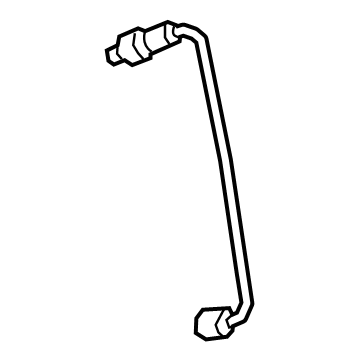

Nissan Rogue Rear Heated Oxygen Sensor

Part Number: 226A0-EN21A$200.53 MSRP: $296.92You Save: $96.39 (33%)Ships in 1-3 Business Days

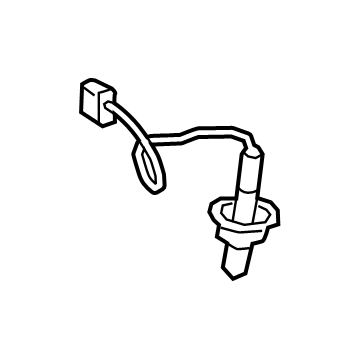

Nissan Rogue Heated Oxygen Sensor

Part Number: 226A0-JA10C$217.41 MSRP: $321.92You Save: $104.51 (33%)Ships in 1-3 Business Days

Nissan Rogue Rear Heated Oxygen Sensor

Part Number: 226A0-9BF0B$219.49 MSRP: $325.00You Save: $105.51 (33%)Ships in 1-2 Business Days

Nissan Rogue Air Fuel Ratio Sensor Assembly

Part Number: 22693-ZX70A$232.90 MSRP: $344.85You Save: $111.95 (33%)Ships in 1-2 Business Days

Nissan Rogue Air Fuel Ratio Sensor Oxygen Sensor

Part Number: 22693-1NA0A$264.83 MSRP: $404.20You Save: $139.37 (35%)Ships in 1-2 Business Days

Nissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-4CL0A$260.60 MSRP: $385.87You Save: $125.27 (33%)Ships in 1-3 Business Days

Nissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-JA00B$219.46 MSRP: $324.97You Save: $105.51 (33%)Ships in 1-3 Business Days

Nissan Rogue Heated Oxygen Sensor

Part Number: 226A4-JA00A$196.05 MSRP: $290.28You Save: $94.23 (33%)Ships in 1-2 Business Days

Nissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-JA00A$219.46 MSRP: $324.97You Save: $105.51 (33%)Ships in 1-2 Business DaysNissan Rogue Sensor Assy Air Fuel Ratio

Part Number: 22693-6CA0C$175.04 MSRP: $259.18You Save: $84.14 (33%)Ships in 1-3 Business DaysNissan Rogue Rear Heated Oxygen Sensor

Part Number: 226A0-6CC0B$90.00 MSRP: $130.35You Save: $40.35 (31%)Ships in 1-3 Business DaysNissan Rogue Sensor Assembly Air Fuel Ratio

Part Number: 22693-5RB0A$263.15 MSRP: $389.65You Save: $126.50 (33%)Ships in 1-3 Business DaysNissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-4BA0A$244.65 MSRP: $362.25You Save: $117.60 (33%)Ships in 1-3 Business DaysNissan Rogue Heated Oxygen Sensor

Part Number: 226A0-6RC1B$168.29 MSRP: $249.18You Save: $80.89 (33%)Ships in 1-3 Business DaysNissan Rogue AIR FUEL RATIO SENSOR

Part Number: 22693-6RC1B$276.44 MSRP: $421.92You Save: $145.48 (35%)Ships in 1-3 Business DaysNissan Rogue Rear Heated Oxygen Sensor

Part Number: 226A0-5CA0A$214.04 MSRP: $316.93You Save: $102.89 (33%)Ships in 1-3 Business DaysNissan Rogue Air Fuel Ratio Sensor

Part Number: 22693-6RC0A$276.73 MSRP: $422.37You Save: $145.64 (35%)Ships in 1-3 Business DaysNissan Rogue Heated Oxygen Sensor

Part Number: 226A0-6RC1A$270.41 MSRP: $412.72You Save: $142.31 (35%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

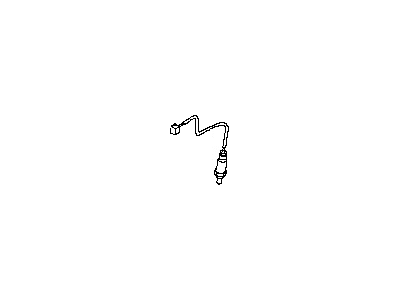

Nissan Rogue Oxygen Sensor

If you need any OEM Nissan Rogue Oxygen Sensor, feel free to choose them out of our huge selection of genuine Nissan Rogue Oxygen Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Rogue Oxygen Sensor Parts Questions & Experts Answers

- Q: What are the precautions to take when servicing an oxygen sensor on Nissan Rogue?A:Be cautious when servicing an oxygen sensor since it has a permanently attached pigtail and electrical connector that should not be removed. Removing the pigtail or electrical connector can make the sensor to stop functioning properly. Stay away from dirt and grease on the louvered end of the sensor and electrical connector. Avoid using any cleaning solvents on the oxygen sensor. It is not recommended that you drop or mishandle it roughly. The silicone boot needs to be placed rightly so as to prevent melting and also allow for proper operation of the sensor. Locate the electrical connector and disconnect it in order to replace an upstream oxygen sensor. Separate the clips from which the sensor wiring harness is hung. In case you have an oxygen socket, unscrew it using one. You will possibly have to lift up the vehicle securely with jackstands so as reach it properly. If reinstalling old sensors, put anti-seize compounds on threads for easier removal at a future date. Anti-seize is already present on new sensors' threads before installation though. The installation process is just undoing everything that was done when removing something. Tighten down firmly by hand again for safety reasons. To install a downstream oxygen sensor: raise your car, secure it using jack stands; disconnect wiring harness from pigtail of this sensor; unscrew with an oxygen socket if available; For installing old sensors only, apply anti-seize compound to threads for easy removal later; New ones always come with anti-seize on their threads, so don't add more of this; Installation part reverses everything that had been done during un-installation hence tighten hand tight again for security purposes.

Related Nissan Rogue Parts

Browse by Year

2025 Oxygen Sensor 2024 Oxygen Sensor 2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor