×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

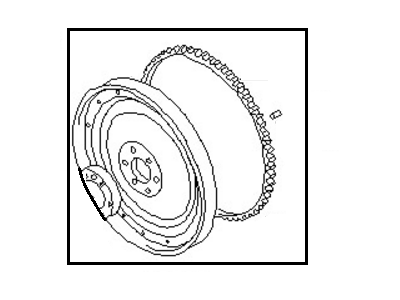

Genuine Nissan Sentra Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Flywheels found

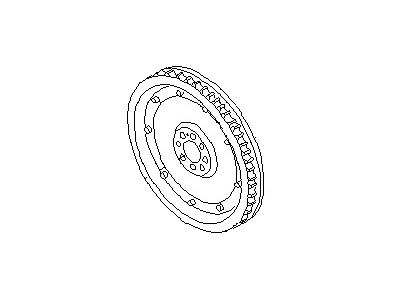

Nissan Sentra Flywheel Assembly

Part Number: 12310-ET02C$720.86 MSRP: $1018.17You Save: $297.31 (30%)Ships in 1-2 Business Days

Nissan Sentra Flywheel Assembly

Part Number: 12310-ET80B$411.10 MSRP: $580.65You Save: $169.55 (30%)Ships in 1-3 Business Days

Nissan Sentra Flywheel Assembly

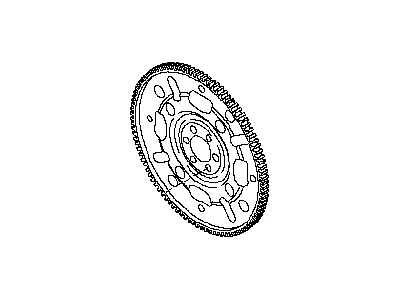

Part Number: 12310-4BB0A$1151.07 MSRP: $1625.80You Save: $474.73 (30%)Ships in 1-3 Business DaysNissan Sentra Drive & Gear Plate Assembly

Part Number: 12331-ED00A$389.36 MSRP: $549.95You Save: $160.59 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-8H301$484.57 MSRP: $684.42You Save: $199.85 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-ET00A$720.86 MSRP: $1018.17You Save: $297.31 (30%)Ships in 1-3 Business DaysNissan Sentra Drive & Gear Plate Assembly

Part Number: 12331-1KC0B$422.27 MSRP: $596.43You Save: $174.16 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-ET01C$720.86 MSRP: $1018.17You Save: $297.31 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-F460A$367.75 MSRP: $494.68You Save: $126.93 (26%)Ships in 1-3 Business DaysNissan Sentra PLATE-DRV&GEAR

Part Number: 12331-6LY0A$133.15 MSRP: $188.07You Save: $54.92 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-ET000$720.86 MSRP: $1018.17You Save: $297.31 (30%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-1M200$357.94 MSRP: $481.49Limited AvailabilityYou Save: $123.55 (26%)Nissan Sentra Flywheel Assembly

Part Number: 12310-4M700$367.75 MSRP: $494.68You Save: $126.93 (26%)Ships in 1-3 Business DaysNissan Sentra Flywheel Assembly

Part Number: 12310-62J02$244.76 MSRP: $340.03Limited AvailabilityYou Save: $95.27 (29%)Nissan Sentra Flywheel Assembly

Part Number: 12310-62J01$244.76 MSRP: $340.03Limited AvailabilityYou Save: $95.27 (29%)Nissan Sentra Flywheel Assembly

Part Number: 12310-62J00$244.76 MSRP: $340.03Limited AvailabilityYou Save: $95.27 (29%)Nissan Sentra Flywheel Assembly

Part Number: 12310-F4300$357.94 MSRP: $481.49Limited AvailabilityYou Save: $123.55 (26%)

| Page 1 of 2 |Next >

1-20 of 29 Results

Nissan Sentra Flywheel

If you need any OEM Nissan Sentra Flywheel, feel free to choose them out of our huge selection of genuine Nissan Sentra Flywheel. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Sentra Flywheel Parts Questions & Experts Answers

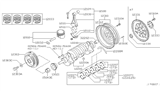

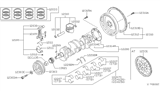

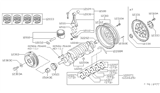

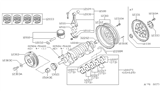

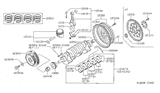

- Q: How to remove and reinstall the engine/transaxle assembly, including handling the flywheel/driveplate and associated components on Nissan Sentra?A:To perform this removal, first you have to unbolt the transaxle from the engine. If you can see a manual transaxle, then remove the pressure plate and the clutch disc. On the assembly procedure to be followed, use a center-punch or a paint to make alignment marks on the flywheel/driveplate and the crankshaft to facilitate correct reassembly. There are bolts holding the flywheel or the driveplate to the crankshaft; therefore, undo these bolts and then pull out the flywheel or the driveplate. For installation, it should be cleaned so as to be free from grease and oil; in this process, cracked or scored condition of the flywheel may be observed and can be repaired by using emery cloth. Examine the flywheel/driveplate mating surfaces and the crankshaft for leaks and if leaking replace the crankshaft rear seal. Align the marked points soon and fixing the flywheel/driveplate with the crankshaft, now fitting the spacer if it was required. To prevent seizing of the bolt threads, smear a thin layer of the thread-locking compound before finally tightening the bolts in a star-wedge motion till the final torque is reached. The remaining steps of the installation revert to a reverse order of the removal procedures and lastly reconnect the battery together with performing the required number of re-learn procedures.

Related Nissan Sentra Parts

Browse by Year

2024 Flywheel 2023 Flywheel 2022 Flywheel 2021 Flywheel 2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2010 Flywheel 2009 Flywheel 2008 Flywheel 2007 Flywheel 2006 Flywheel 2005 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1996 Flywheel 1995 Flywheel 1994 Flywheel 1993 Flywheel 1992 Flywheel 1991 Flywheel 1990 Flywheel 1989 Flywheel 1988 Flywheel 1987 Flywheel 1986 Flywheel 1985 Flywheel 1984 Flywheel 1983 Flywheel 1982 Flywheel