×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Titan Differential Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Differential Seals found

Nissan Titan Oil Seal

Part Number: 38189-EZ40A$33.97 MSRP: $46.83You Save: $12.86 (28%)Ships in 1-3 Business Days

Nissan Titan Seal-Oil,Drive Pinion

Part Number: 38189-8S100$26.85 MSRP: $37.02You Save: $10.17 (28%)Ships in 1-2 Business Days

Nissan Titan Oil Seal

Part Number: 38189-EZ20B$30.71 MSRP: $42.33You Save: $11.62 (28%)Ships in 1-3 Business Days

Nissan Titan Oil Seal

Part Number: 38189-EZ40B$29.54 MSRP: $40.72You Save: $11.18 (28%)Ships in 1-3 Business Days

Nissan Titan Oil Seal

Part Number: 38189-EZ20A$25.84 MSRP: $35.62You Save: $9.78 (28%)Ships in 1-3 Business Days

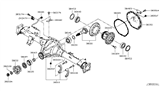

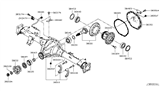

Nissan Titan Differential Seal

If you need any OEM Nissan Titan Differential Seal, feel free to choose them out of our huge selection of genuine Nissan Titan Differential Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Titan Differential Seal Parts Questions & Experts Answers

- Q: How to replace a differential pinion seal on Nissan Titan?A:Firstly, in order to start the process of replacing the differential pinion seal, you have to loosen the lug nuts on the wheels and firmly raise the front or back of your vehicle with jacks while blocking off any other wheels to prevent them from moving . After this, take off your wheels and remove driveshaft from the differential companion flange and set it aside. Next, remove the rear brake discs and rotate manually a pinion shaft several times. Using a beam-type or dial-type inch-pound torque wrench measure torque needed for pinion rotation and note down this value for reference. Also, mark the position between pinion flange and shaft; count exposed threads over nut and note among others things about these details. In order to release a self-locking pinion nut use a flange holding tool, which will prevent movement of the companion flange. The nut is pulled carefully out by using two-jaw pullers if necessary. No attempt should be made at prying or hammering behind the flange or at hammering on the end of pinion shaft. Then pry out, discard old seal. After lubricating lips of new seal, fill wheel bearing grease into space between its lips evenly tapped into place with large socket while ensuring it sits squarely as well as reaches full depth within housing using either a seal installation tool or large socket.. While aligning marks that were previously made install pinion flange into place. If necessary, tighten pinion nut to draw flange into place without any need for hammering on it. Apply RTV sealant to visible ends of splines sticking out in middle of flanges as shown between arrows to seal in oil (Fig. 12). Install new pinion nut followed by new lockwasher (never reuse old ones) and tighten nut (Fig 11). Meanwhile recheck torque necessary for correct rotation rate of pinion and tighten gradually incrementally not exceeding 5ft-lbs until it increases to the value recorded. Finally, tighten the nut slightly more to accommodate new oil seal's drag, until pinion's rotational torque is 5 in-lbs greater than that previously recorded. Warning: if desired preload is not achieved before the maximum nut torque is reached, the differential should be disassembled and a new collapsible spacer installed. Re-install all items previously removed after reversing the steps for removal and tighten fasteners to specified torque values.

Related Nissan Titan Parts

Browse by Year

2024 Differential Seal 2023 Differential Seal 2022 Differential Seal 2021 Differential Seal 2020 Differential Seal 2019 Differential Seal 2018 Differential Seal 2017 Differential Seal 2016 Differential Seal 2015 Differential Seal 2014 Differential Seal 2013 Differential Seal 2012 Differential Seal 2011 Differential Seal 2010 Differential Seal 2009 Differential Seal 2008 Differential Seal 2007 Differential Seal 2006 Differential Seal 2005 Differential Seal 2004 Differential Seal