×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

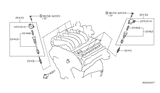

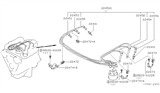

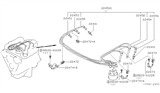

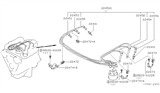

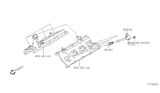

Genuine Nissan Titan Spark Plug

Ignition Spark Plug- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Spark Plugs found

Nissan Titan Spark Plug

Part Number: 22401-ZE01B$20.12 MSRP: $29.15You Save: $9.03 (31%)Ships in 1-3 Business Days

Nissan Titan Spark Plug

Part Number: 22401-5M014$14.93 MSRP: $21.62You Save: $6.69 (31%)Ships in 1-3 Business Days

Nissan Titan Spark Plug

Part Number: 22401-5M015$14.60 MSRP: $21.15You Save: $6.55 (31%)Ships in 1-2 Business Days

Nissan Titan Spark Plug

Part Number: 22401-5M016$12.98 MSRP: $18.80You Save: $5.82 (31%)Ships in 1-3 Business Days

Nissan Titan Spark Plug

Part Number: 22401-ZJ51B$19.92 MSRP: $28.85You Save: $8.93 (31%)Ships in 1-2 Business Days

Nissan Titan Spark Plug

Part Number: 22401-ZH015$12.38 MSRP: $17.93You Save: $5.55 (31%)Ships in 1-3 Business DaysNissan Titan Spark Plug

Part Number: 22401-1LA1C$27.13 MSRP: $39.30You Save: $12.17 (31%)Ships in 1-2 Business DaysNissan Titan Spark Plug

Part Number: 22401-ZH016$12.66 MSRP: $18.33You Save: $5.67 (31%)Ships in 1-3 Business Days

Nissan Titan Spark Plug

If you need any OEM Nissan Titan Spark Plug, feel free to choose them out of our huge selection of genuine Nissan Titan Spark Plug. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Titan Spark Plug Parts Questions & Experts Answers

- Q: How to replace spark plugs in an engine on Nissan Titan?A:The manufacturer discourages inspecting spark plug gap on those that have been used for fear of scratching off the platinum or iridium coating that will lead to rapid wear. Among other tools, a spark plug socket, ratchet and different extensions are necessary when replacing spark plugs. Allow the engine to cool completely before removing any plugs and during this time, check the new ones for defects. At one cylinder, disconnect the electrical connector at the Ignition Coil and remove the bolt, then lift up on the coil/plug boot assembly in order to access the spark plug below. If possible blow dirt or foreign material out of spark plug hole using compressed air to avoid debris dropping into cylinder. Unscrew the spark plugs counterclockwise with a spark plug socket and extension. Compare ispark plug with chart provided to gauge overall running condition of engine. A thin layer of anti-seize compound must be applied to threads before installing new plugs without getting any compound near the lower threads. Turn one of the new plugs into the hole by hand until it can't be turned anymore, then tighten it with a torque wrench or ratchet. To screw in plug use length short rubber hose as tool thus avoiding damaged threads. Change position manually twist boot around tip till properly seated ignition coil, then secure bolt tightly in place Repeat this process for remaining spark plugs.

Related Nissan Titan Parts

Browse by Year

2024 Spark Plug 2023 Spark Plug 2022 Spark Plug 2021 Spark Plug 2020 Spark Plug 2019 Spark Plug 2018 Spark Plug 2017 Spark Plug 2016 Spark Plug 2015 Spark Plug 2014 Spark Plug 2013 Spark Plug 2012 Spark Plug 2011 Spark Plug 2010 Spark Plug 2009 Spark Plug 2008 Spark Plug 2007 Spark Plug 2006 Spark Plug 2005 Spark Plug 2004 Spark Plug