×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Titan Transfer Case

Speed Transfer Case- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Transfer Cases found

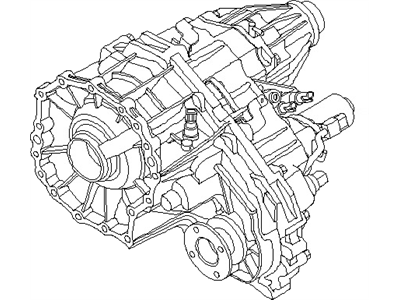

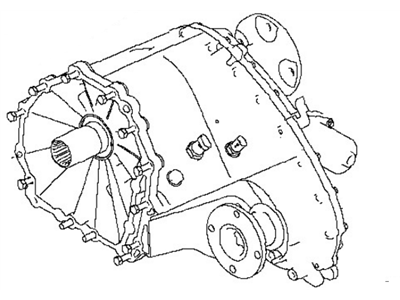

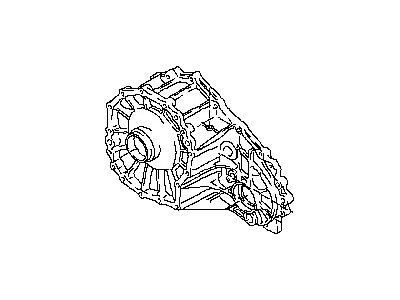

Nissan Titan Transfer Assembly

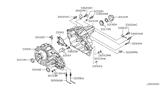

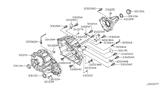

Part Number: 33100-EA33A$2865.36 MSRP: $3468.96You Save: $603.60 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EZ20A$2783.84 MSRP: $3370.27You Save: $586.43 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EZ50B$1080.48 MSRP: $1526.10You Save: $445.62 (30%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EZ00A$2534.39 MSRP: $3068.27You Save: $533.88 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EA310$2865.36 MSRP: $3468.96You Save: $603.60 (18%)Ships in 1-3 Business DaysNissan Titan Case Transfer Front

Part Number: 33107-8S01C$573.69 MSRP: $810.30You Save: $236.61 (30%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EZ30A$2819.24 MSRP: $3413.13You Save: $593.89 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EA31B$2865.36 MSRP: $3468.96You Save: $603.60 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-8S010$3033.65 MSRP: $3672.70You Save: $639.05 (18%)Ships in 1-3 Business DaysNissan Titan Transfer Assembly

Part Number: 33100-EZ60A$3709.28 MSRP: $4490.66You Save: $781.38 (18%)Ships in 1-3 Business Days

Nissan Titan Transfer Case

If you need any OEM Nissan Titan Transfer Case, feel free to choose them out of our huge selection of genuine Nissan Titan Transfer Case. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Titan Transfer Case Parts Questions & Experts Answers

- Q: Is overhauling a transfer case a challenging task for a do-it-yourselfer on Nissan Titan?A:Rebuilding a transfer case is not an easy task for a do-it-yourselfer; for it involves dismantling of many small parts and rebuilding them again and the measurements of clearance are exact and need adjustment through the help of select-fit spacers and snap-rings. While it is possible to change the transfer case or install a new one, the overhaul is better left to a transaxle repair shop for reasons of time and cost; a rebuilt transfer case may be obtainable via a manufacturer's dealer parts department as well as from auto part stores. It should be noted that even though the above teardown was carried out by an experienced mechanic and highlighted nuances that an inexperienced mechanic might miss, an inexperienced mechanic can also successfully rebuild a transfer case if he has the needed special tools and approach the procedure methodically. Required tools that may be needed include internal and external snap-ring pliers, bearing puller, a slide hammer, set of pin punches, dial indicator, possibly a hydraulic press and a large heavy duty workbench. It is equally important during disassembly and dismantling process, one should record and document the connection and the manner that the components are fitted. It can be easier to understand and diagnose the properties of the faulty zone in the transfer case and to trace the potential troubles by checking the codes twisted to the transfer case system.

Related Nissan Titan Parts

Browse by Year

2024 Transfer Case 2023 Transfer Case 2022 Transfer Case 2021 Transfer Case 2020 Transfer Case 2019 Transfer Case 2018 Transfer Case 2017 Transfer Case 2016 Transfer Case 2015 Transfer Case 2014 Transfer Case 2013 Transfer Case 2012 Transfer Case 2011 Transfer Case 2010 Transfer Case 2009 Transfer Case 2008 Transfer Case 2007 Transfer Case 2006 Transfer Case 2005 Transfer Case 2004 Transfer Case