×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Versa ABS Sensor

ABS Wheel Speed Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 ABS Sensors found

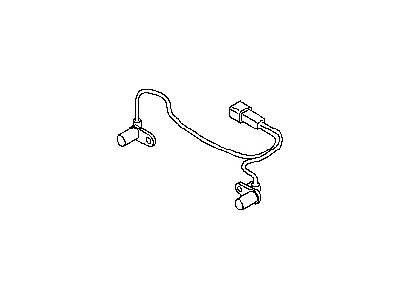

Nissan Versa Sensor Assembly-Anti SKID, Front

Part Number: 47910-1HA0A$189.14 MSRP: $280.07You Save: $90.93 (33%)Ships in 1-3 Business Days

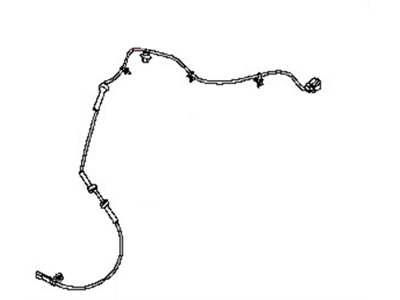

Nissan Versa Anti Skid Sensor Assembly Rear

Part Number: 47900-EL00A$65.58 MSRP: $94.98You Save: $29.40 (31%)Ships in 1-3 Business DaysNissan Versa Sensor Assembly-Anti SKID, Front

Part Number: 47910-5RA0A$161.00 MSRP: $238.40You Save: $77.40 (33%)Ships in 1-3 Business DaysNissan Versa Sensor Assembly Anti Ski, Rear

Part Number: 47900-1HA0A$142.44 MSRP: $210.92You Save: $68.48 (33%)Ships in 1-3 Business DaysNissan Versa Sensor Assy-Antiskid,Rear

Part Number: 47900-5FA0C$25.69 MSRP: $37.22You Save: $11.53 (31%)Ships in 1-3 Business DaysNissan Versa Sensor Assembly Anti Ski, Rear

Part Number: 47901-1HA0A$153.39 MSRP: $227.13You Save: $73.74 (33%)Ships in 1-3 Business DaysNissan Versa Sensor Assembly-Anti SKID, Front

Part Number: 47910-ZR70A$174.20 MSRP: $257.93You Save: $83.73 (33%)Ships in 1-3 Business DaysNissan Versa Sensor Assembly-Anti SKID,Front

Part Number: 47910-EL00A$174.20 MSRP: $257.93You Save: $83.73 (33%)Ships in 1-3 Business Days

Nissan Versa ABS Sensor

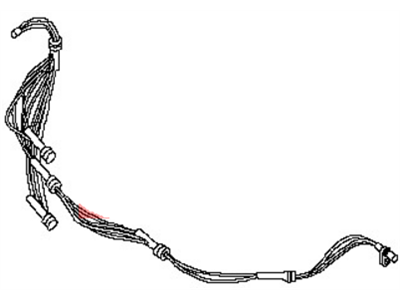

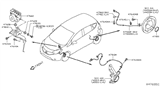

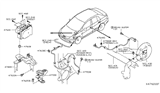

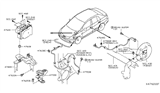

A Nissan Versa vehicle needs its ABS Sensor to function due to its essential role in braking anti-lock safety by tracking wheel rotation to stop wheel lock-up. Under conditions with lost traction the sensor gives necessary data to the vehicle's computer which allows the system to activate. During operation the ABS Sensor creates electrical signals through two methods: either a hall effect sensor linked to a magnet or an electromagnetic coil paired with a toothed wheel. This signal transmission lets the ABS controller determine wheel velocity. Along with other changes Nissan Versa models have implemented various ABS Sensor designs which perform primarily by monitoring wheel speeds. Each ABS Sensor functions to maintain braking safety although their accuracy decreases at reduced speeds because of small magnetic field changes. The Nissan Versa ABS Sensor functions as an essential braking component which delivers functional braking features for different driving situations regardless of its speed detection constraint.

If you need any OEM Nissan Versa ABS Sensor, feel free to choose them out of our huge selection of genuine Nissan Versa ABS Sensor. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa ABS Sensor Parts Questions & Experts Answers

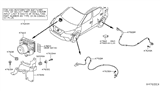

- Q: What is the purpose and functionality of the ABS Sensor,ABS Control Module and Anti-lock Brake System (ABS) on Nissan Versa?A:The described Anti-lock Brake System (ABS) is used to prevent vehicle's wheels from locking by actively modulating the Brake Line pressure for every wheel, which allows for the maintainance of steerability, directional stability, and the optimal amount of deceleration during hard braking on most road surfaces. At the right rear corner of the engine compartment, total of five items such as electric hydraulic pump and two solenoid valves for each wheel are still included in the actuator assembly which is used to control hydraulic pressure during the ABS. At the wheels, speed sensors create a sine wave current as the sensor rotors spin and the ABS control module then amplifies, samples and digitizes this analog voltage signal to obtain the wheel speed. The control unit is one of the main parts of the system and controls the hydraulic line pressure through being the brain of the system that receives information from the wheel speed sensors to avoid wheel lock while at the same time, it checks for a malfunction, even during normal road use. ABS light comes on for a second after starting the engine and should go out if the engine is running properly, the ABS performs a self-test whenever the vehicle speed surpasses four mph; often, this sounds like a normal metallic noise. When a problem is identified, the ABS light will not go off, and a specific code of the problem will be written to the control unit.

Related Nissan Versa Parts

Browse by Year

2025 ABS Sensor 2024 ABS Sensor 2023 ABS Sensor 2022 ABS Sensor 2021 ABS Sensor 2020 ABS Sensor 2019 ABS Sensor 2018 ABS Sensor 2017 ABS Sensor 2016 ABS Sensor 2015 ABS Sensor 2014 ABS Sensor 2013 ABS Sensor 2012 ABS Sensor 2011 ABS Sensor 2010 ABS Sensor 2009 ABS Sensor 2008 ABS Sensor 2007 ABS Sensor