×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Versa CV Boot

Axle Boot- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 CV Boots found

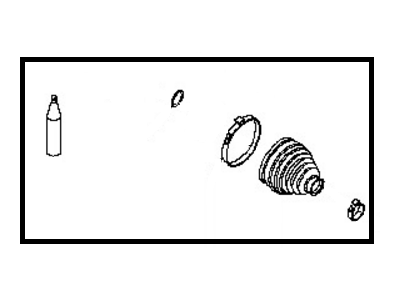

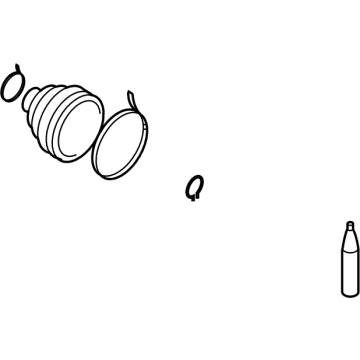

Nissan Versa Repair Kit-Dust Boot,Outer

Part Number: C9241-EL10D$49.34 MSRP: $68.02You Save: $18.68 (28%)Ships in 1-3 Business Days

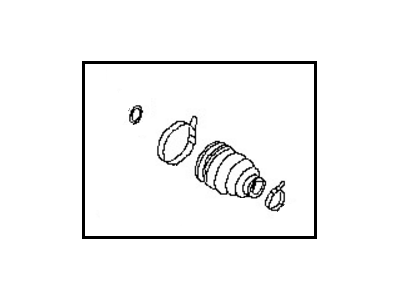

Nissan Versa Repair Kt Outer RH

Part Number: C9241-EL10A$37.83 MSRP: $52.15You Save: $14.32 (28%)Ships in 1-3 Business Days

Nissan Versa Repair Kit-Dust Boot,Outer

Part Number: C9241-EL00B$39.95 MSRP: $55.07You Save: $15.12 (28%)Ships in 1-3 Business Days

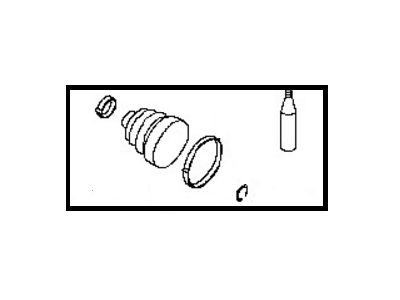

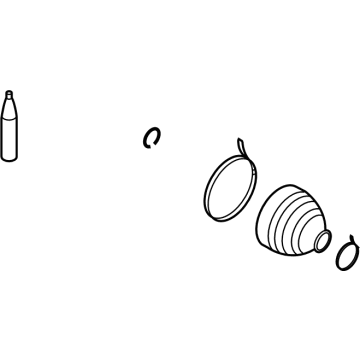

Nissan Versa Repair Kit-Dust B00T,Inner

Part Number: C9741-EL00A$43.31 MSRP: $59.70You Save: $16.39 (28%)Ships in 1-3 Business Days

Nissan Versa Repair Kit-Dust B00T,Inner

Part Number: C9741-ED00A$79.08 MSRP: $111.70You Save: $32.62 (30%)Ships in 1-3 Business DaysNissan Versa Dust Boot Kit-Repair,Inner

Part Number: C9741-ED50A$32.85 MSRP: $45.28You Save: $12.43 (28%)Ships in 1-3 Business DaysNissan Versa Dust Boot Repair Kit Inner

Part Number: C9741-EL10A$34.66 MSRP: $47.78You Save: $13.12 (28%)Ships in 1-3 Business DaysNissan Versa Dust Boot Kit-Repair,Outer

Part Number: C9241-3TC2A$38.37 MSRP: $52.90You Save: $14.53 (28%)Ships in 1-3 Business DaysNissan Versa Dust Boot Kit-Repair,Inner

Part Number: C9741-3TC2A$124.83 MSRP: $176.32You Save: $51.49 (30%)Ships in 1-3 Business DaysNissan Versa Dust Boot Kit-Repair,Inner

Part Number: C9G41-ED00A$71.27 MSRP: $100.67You Save: $29.40 (30%)Ships in 1-3 Business DaysNissan Versa Dust Boot Kit-Repair,Outer

Part Number: C9B41-EL10A$56.44 MSRP: $77.80You Save: $21.36 (28%)Ships in 1-3 Business Days

Nissan Versa CV Boot

If you need any OEM Nissan Versa CV Boot, feel free to choose them out of our huge selection of genuine Nissan Versa CV Boot. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

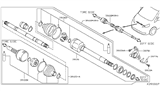

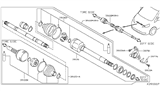

Nissan Versa CV Boot Parts Questions & Experts Answers

- Q: How to replace the CV Boot on Nissan Versa?A:If you have to overhaul the CV joints normally because of destroyed boots, think twice before beginning the work, as completely rebuilt driveaxles can be purchased on an exchange basis, which will ultimately help you to avoid a lot of work. However, the locations of specific components within the structure may require structural disassembly whereupon the cost and availability of spare parts should be checked. For number 2 inner CV joint: To access, first have to remove the driveaxle and the boot clamps and then pull back the boot and unscrew the retaining ring to take out the joint housing. File the tripod and axleshaft to ensure that when assembling the machine again, one will know where to fix it. Using snap-ring pliers, removed the snap-ring from the axleshaft. Hammer and brass punch the tripod joint from the driveaxle cautiously, so that do not mar any of the bearings or splines. Rinse all components with the solvent to feel or check elasticity. The little tips and procedures that should be followed at the reassembly of the part are: When sliding the clamps and boot onto the axleshaft, be careful not to damage the boot and; it is advisable to wrap the splines with some tapes.A step during the reassembly of the part is putting the tripod on the shaft and then snap-ring. Lubricate the tripod assembly, the joint and housing, and the boot and put the housing and the ring back, the boot must fit in correctly. Change the position of the joint length, balance pressure in the boot as well as applying the clamps then place a new circlip at the inner CV joint stub axle as well as the drive axel. For the outer CV joint, first dismantle the drive axle and boot clamps and then refer to the boot replacement process, a slide hammer may be used if required to pull out the outer CV joint. The surfaces which come into contact should be observed for signs of wear and damage, then grease is applied to the joint, and boot and clamps have to be fitted on to the splined portion. Last, locate the CV joint assembly on the drive axel, lineup the splines and slide the joint onto the drive axel, adjust boot and equalizing pressure and then use clamps to tight.