×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Versa Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Headlights found

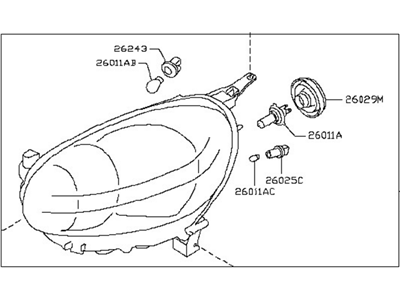

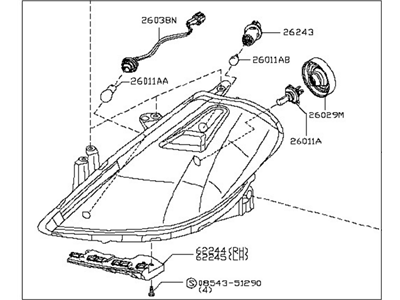

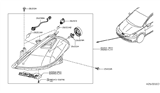

Nissan Versa Passenger Side Headlight Assembly

Part Number: 26010-9KK0A$164.81 MSRP: $253.95You Save: $89.14 (36%)Ships in 1-2 Business Days

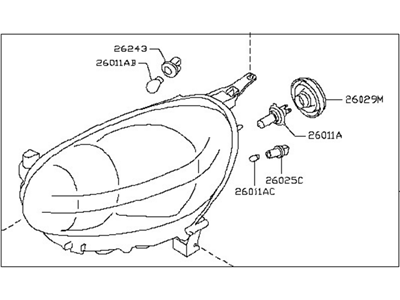

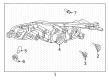

Nissan Versa Headlamp Assembly-Driver Side

Part Number: 26060-9KK0A$164.81 MSRP: $253.95You Save: $89.14 (36%)Ships in 1-3 Business Days

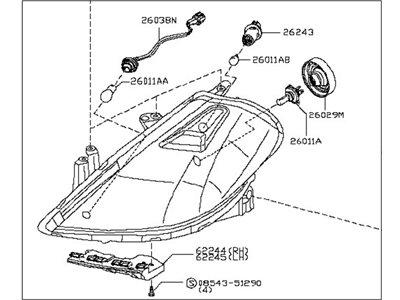

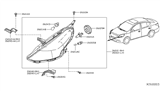

Nissan Versa Driver Side Headlight Assembly

Part Number: 26060-EM30A$236.76 MSRP: $364.80You Save: $128.04 (36%)Ships in 1-3 Business Days

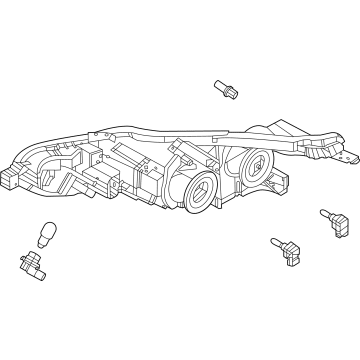

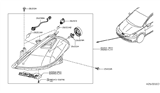

Nissan Versa Headlamp Assy-Lh

Part Number: 26060-5EE2A$728.04 MSRP: $1121.78You Save: $393.74 (36%)Ships in 1-3 Business Days

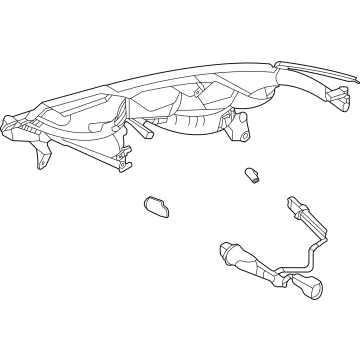

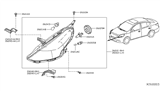

Nissan Versa Passenger Side Headlamp Assembly

Part Number: 26010-3AN0B$311.69 MSRP: $480.25You Save: $168.56 (36%)Ships in 1-3 Business Days

Nissan Versa Passenger Side Headlight Assembly

Part Number: 26010-EM30A$236.76 MSRP: $364.80You Save: $128.04 (36%)Ships in 1-3 Business Days

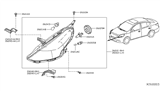

Nissan Versa Driver Side Headlight Assembly

Part Number: 26060-3AN0B$311.69 MSRP: $480.25You Save: $168.56 (36%)Ships in 1-3 Business DaysNissan Versa Headlamp Assy-Lh

Part Number: 26060-5EE3A$360.09 MSRP: $554.84You Save: $194.75 (36%)Ships in 1-3 Business DaysNissan Versa Right Hand Headlamp Assembly

Part Number: 26010-5EE0A$397.41 MSRP: $612.35You Save: $214.94 (36%)Ships in 1-3 Business DaysNissan Versa Headlamp Assy-Lh

Part Number: 26060-5EE0A$397.41 MSRP: $612.35You Save: $214.94 (36%)Ships in 1-3 Business DaysNissan Versa Right Hand Headlamp Assembly

Part Number: 26010-5EE3A$360.09 MSRP: $554.84You Save: $194.75 (36%)Ships in 1-3 Business DaysNissan Versa Right Hand Headlamp Assembly

Part Number: 26010-5EE2A$728.04 MSRP: $1121.78You Save: $393.74 (36%)Ships in 1-3 Business Days

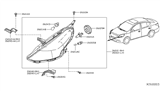

Nissan Versa Headlight

If you need any OEM Nissan Versa Headlight, feel free to choose them out of our huge selection of genuine Nissan Versa Headlight. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Versa Headlight Parts Questions & Experts Answers

- Q: How can you ensure that your headlights are aimed correctly to avoid blinding oncoming drivers and maintain optimal visibility on the road on Nissan Versa?A:This is because faulty alignment of tile headlights is a hazard since other drivers on the road are likely to be blinded and at the same time ensure that everyone on the road is clearly visible. Headlights should be checked regarding their position every 1 year and if new headlight has been installed or front end body works have been done. The following procedure is a little fix until the actual alignment can be done by an expert. Both headlights on the driver's side of the vehicle contain one adjustment screw that can be accessed using a Phillips head screw driver. This method also needs wall, masking tape and the floor should be level. Tape the masking tape standing vertically to the wall in a position that corresponds to the vehicle and the centerline of the pair of headlights, it is also helpful to lay down a horizontal line on the wall next to it. The car should be 25 feet from the wall it should be leveled and the fuel gauge should be slightly above a quarter full and the car should not be carrying any heavy load. Regarding low beam adjustment, align the high-intensity area two inches below the top of the light beam. Switch on the high beam and make sure that high-intensity zone is aligned vertically half an inch below the horizontal line meridian. In case of compromise, aim at protecting the low beams that are frequently used in a car more than the high beams. These should be adjusted by a dealer service department or service center as soon as possible.