×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Versa Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Oil Pans found

Nissan Versa Oil Pan Assembly

Part Number: 31390-31X0A$50.76 MSRP: $71.70You Save: $20.94 (30%)Ships in 1-2 Business Days

Nissan Versa Oil Pan Assembly

Part Number: 31390-1XB01$69.97 MSRP: $98.83You Save: $28.86 (30%)Ships in 1-2 Business Days

Nissan Versa Oil Pan Assembly

Part Number: 31390-3JX1A$73.29 MSRP: $103.52You Save: $30.23 (30%)Ships in 1-3 Business Days

Nissan Versa Oil Pan Assembly

Part Number: 31390-X420B$38.64 MSRP: $53.27You Save: $14.63 (28%)Ships in 1-3 Business Days

Nissan Versa Oil Pan Assembly

Part Number: 31390-X425A$43.45 MSRP: $59.90You Save: $16.45 (28%)Ships in 1-3 Business Days

Nissan Versa Oil Pan Assembly

Part Number: 11110-ET010$98.40 MSRP: $138.98You Save: $40.58 (30%)Ships in 1 Business Day

Nissan Versa Oil Pan Assembly

Part Number: 31390-31X00$41.31 MSRP: $56.95You Save: $15.64 (28%)Ships in 1-3 Business Days

Nissan Versa Oil Pan Assembly

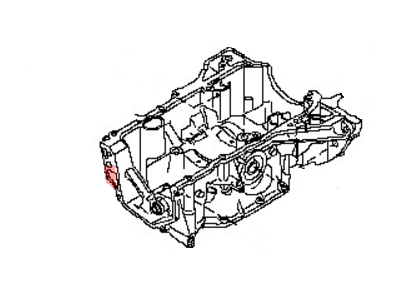

Part Number: 31390-3JX0A$73.29 MSRP: $103.52You Save: $30.23 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-5RB1A$125.50 MSRP: $177.27You Save: $51.77 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-3HC1A$142.96 MSRP: $201.92You Save: $58.96 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 31390-3MX0A$72.78 MSRP: $102.80You Save: $30.02 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-3HC0A$413.77 MSRP: $584.42You Save: $170.65 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-5RB0A$219.89 MSRP: $310.58You Save: $90.69 (30%)Ships in 1-3 Business DaysNissan Versa Pan Assembly Oil

Part Number: 11110-ED010$123.98 MSRP: $175.12You Save: $51.14 (30%)Ships in 1-3 Business DaysNissan Versa Pan Assembly Oil

Part Number: 11110-EM30B$283.72 MSRP: $400.73You Save: $117.01 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-5RB0B$406.06 MSRP: $573.53You Save: $167.47 (30%)Ships in 1-3 Business DaysNissan Versa Oil Pan Assembly

Part Number: 11110-EM30A$283.72 MSRP: $400.73You Save: $117.01 (30%)Ships in 1-3 Business Days

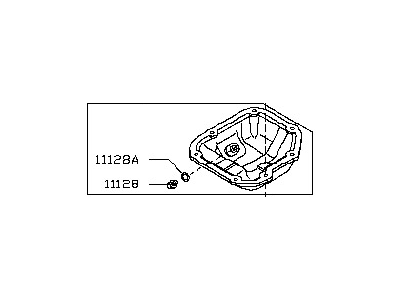

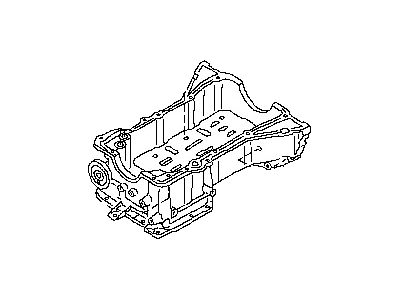

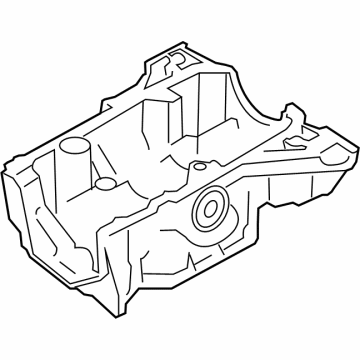

Nissan Versa Oil Pan

If you need any OEM Nissan Versa Oil Pan, feel free to choose them out of our huge selection of genuine Nissan Versa Oil Pan. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

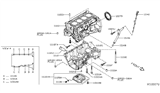

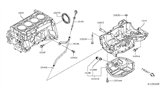

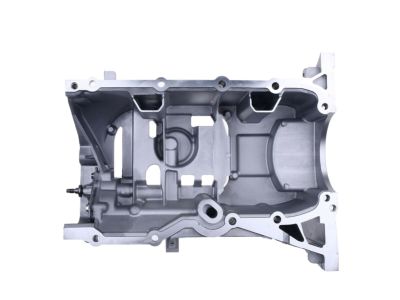

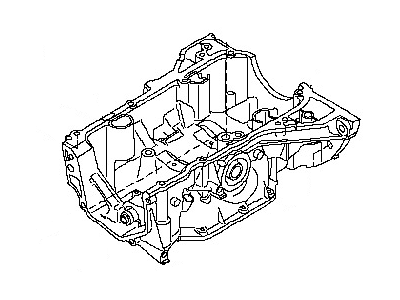

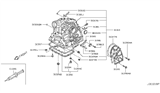

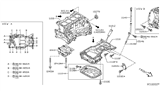

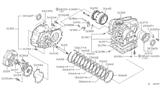

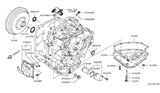

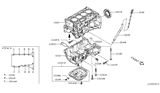

Nissan Versa Oil Pan Parts Questions & Experts Answers

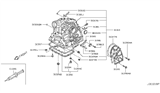

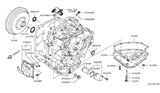

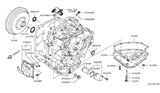

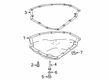

- Q: How to remove and install the oil pans on Nissan Versa?A:The procedure entails the total detachment of two pans- the lower steel oil pan and the upper aluminum oil pan but if only the lower pan is to be removed, many steps cannot be followed because of its assessable nature. As for the upper oil pan, it is recommended to remove the engine on 1.8L power units, thereby steps that are chosen based on this information can be considered as irrelevant. First you should remove the negative battery cable, then loosen the lug nuts of the right front wheel, after that jack up the car and secure it on jack stands and finally take off the wheel. Suck out the engine oil, unfasten the front part of the exhaust pipe and detach the drive belts. Next, the timing chain cover and timing chain need to be dismantled and further the oil pump drive chain and sprocket also have to be removed. The oil pan comes as two main sections, with the main steel pan fixed to an aluminum extension that is fastened to the engine block; it is recommended that removal of the bolts holding the oil pan be done gradually in a crisscross fashion and then the steel pan can be pulled apart by using a thin putty knife. One has to be very careful not to mar the sealing surface in any way. Stake each bolt for identification stating that the oil pump screen is fixed to the oil pan for 1.8L engines or the oil pump for 1.6L engines. Unfasten the bolts securing the aluminum section to the engine block by the same sequence as you applied when tightening them and also, it is advisable to cut through the sealant around the aluminum section with a flat blade between it and the transaxle. For installation, clean up the block and the oil pan by removing any gasket and sealant material adhering to the two or with screw drivers do not scratch the gasket surfaces. When using a steel pan flange, one usually measures the flange for distortions and correct them if there are any. Dependent on vehicle, it is recommended that a 3/16-inch wide bead of RTV sealant is applied to the surrounding of the aluminium section and installation should be done within 15 mins. If new O-rings are required then fit them, and place the aluminium section in the position on the engine block and secure the bolts in the specified torque sequence. Squash RTV sealant around the periphery of the steel pan and fit it before the bolts grow tight; do it diagonally. Perform this in reverse of the removal steps, and also replace a new oil filter on this engine before tightening it and let the RTV set for approximately 30 minutes before pouring the oil. Last, reconnect the battery and do the re learn if needed.