×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

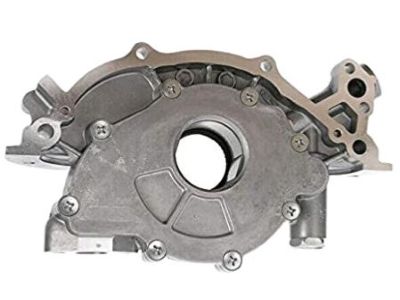

Genuine Nissan 240SX Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Oil Pumps found

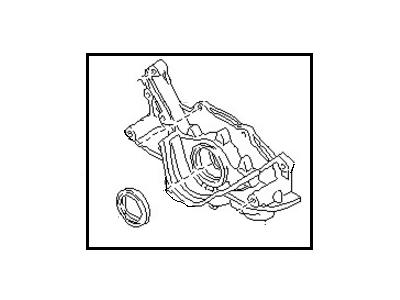

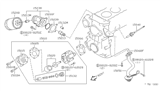

Nissan 240SX Gear Assembly-Drive

Part Number: 15020-53F25$76.85 MSRP: $108.55You Save: $31.70 (30%)Ships in 1-2 Business Days

Nissan 240SX Oil Pump

If you need any OEM Nissan 240SX Oil Pump, feel free to choose them out of our huge selection of genuine Nissan 240SX Oil Pump. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Oil Pump Parts Questions & Experts Answers

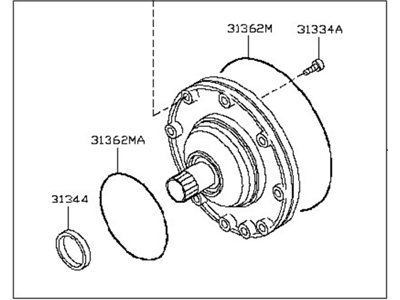

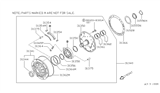

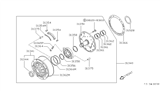

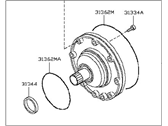

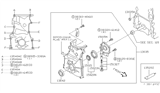

- Q: How to remove and install an oil pump in Nissan 240sx?A:Before removing the oil pump, be sure to drain the oil from the Oil Pan and stick No. 1 piston at TDC on compression stroke marking the distributor rotor position. Removing involves removing the oil pump body with its drive spindle assembly as well as front stabilizer bar (if any) and splash shield. When installing, fill engine oil in the pump housing, align the hole in the pump with punch mark on spindle, and ensure that number one piston is at TDC on compression stroke. Over the drive spindle, use a new gasket apply to install the oil pump and drive spindle assembly carefully aligned to distributor shaft correctly. Be careful during installation not to disturb rotor of distributor which can cause ignition timing problems. Put back these parts into their previous positions, refill engine oil and check if there are any leaks or problems with timing of operation. For CA series engines, this means draining the oil pan; removing accessory drive belts; Alternator; timing belt covers and timing belt; lifting or jacking up engine; taking off oil pan lastly and thereafter remove an entire assembly of an oil pump together with an oil strainer replacing its front seal in this process. In Stanza models equipped with KA24E engines, one must first remove the front cover to access it before disassembling it completely. This consists of dismantling and inspecting regulator valve components for wear and damage; making sure that valve slides smoothly in a valve bore, especially checking if its spring is also functioning well. Other checks include measurement clearances of various parts as well as body-to-gear clearance where every case exceeding limits requires gearbox set or another set of an oil pump assembly. For inspection purposes, including verification of gears/body clearance among other things, one should focus on KA24DE engines found in 240SX models only. To put together this device do not forget about using new O-rings for sealing outlets properly coated gears with lubricant and oil pump cover fixed with the required force. For VG30 and VG30E engines in 200SX models, removal includes a series of steps such as removing the oil pan, timing belt, crankshaft timing sprocket, timing belt plate, oil pump strainer, and oil pump assembly. Application requires cleaning mating surfaces; applying fresh liquid gasket bead; applying lubricant to gear teeth and new O-rings/seals while fitting an oil pump into place. Finally, for Stanza models with KA24E engines manufactured between 1990-92 years disassembly/inspection will be similar to other models after which one should install them with right torque specifications using jelly petroleum to avoid cavitation.