×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 240SX Radius Arm

Front Suspension Radius Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Radius Arms found

Nissan 240SX Rod Tension

Part Number: 54468-35F20$166.56 MSRP: $235.25You Save: $68.69 (30%)Ships in 1-3 Business Days

Nissan 240SX Radius Arm

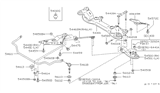

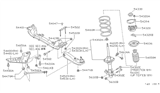

A vital part of Nissan 240SX suspension systems are Radius Arms which professionals call radius rods or torque arms for their function in controlling wheel movement to improve steering control. Named the Radius Arm the component connects the axle to vehicle frame structure to prevent wheel movement beyond limits which produces dependable handling and steering control. The Radius Arm builders utilize stamped steel or aluminum for their construction because these materials provide an optimal combination of weight reduction and operational effectiveness. The 240SX accepts different Radius Arm configurations which include transverse and longitudinal styles that function according to vehicle demands and road situations. Transverse Radius Arms function in trucks as a lateral load absorption mechanism and longitudinal arms control acceleration and braking-related excursions. A wristed Nissan Radius Arm featuring its bent construction delivers improved mobility to the suspension system. The performance together with safety ratings of any vehicle directly result from its Nissan 240SX replacement part's structural design and component materials.

If you need any OEM Nissan 240SX Radius Arm, feel free to choose them out of our huge selection of genuine Nissan 240SX Radius Arm. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 240SX Radius Arm Parts Questions & Experts Answers

- Q: How do you remove and install front Radius Arm and Sway Bar Kit on Nissan 240sx?A:For both the 200SX and 240SX to have access to these particular segments start by lifting up the car by the use of jack and then support it using stands. Take off the lock nuts for tension rod to frame by the way of taking out the two mounting bolts of the transverse link and lower Control Arm, and subsequently taking out the tension rod. For the 240SX, take off the bolt and nut that holds the rod on the tension rod bracket and move the rod in the upward position and take off the bolts, nuts and bushings of the transverse link and check for the condition of the bushing where one may have to be replaced. Loosen at least the nuts at each transverse link or connecting rod; and to do that, you need to hold the sway bar kit connecting rod to stop it from turning with a wrench. Next, unbolt the four sway bar kit bracket bolts and, then, take out the sway bar kit. During installation, torque the sway bar kit-to-transverse link bolts to 12-16 ft.-lbs. and 34-38 ft. lbs. should be torqued to 22-29 ft-lbs for the 240SX, the sway bar kit bracket bolts can be torqued to 40-50 ft. lbs. and 29-36 ft. lbs. for the 240SX. The tension rod to transverse link nuts should be tightened up to a torque of 31-43 ft. lbs., while the plain nuts could be tightened with 65-80 ft. lbs on the 240SX. and the nuts with bushing and washers at 14-22 ft. lbs., thus making sure that the connecting rod cannot move. Tightening of the tension rod-to-frame nut should be to 33-40 ft. lbs., the objective was to reconnect the collet and shank which required the use of a new locknut. Make sure the tension rod bushings are properly in place and the sway bar kit ball joint socket is also positioned right, before applying final torque on any bolt or nut while it is the ground. For lists the following changes to be made, Starting first with lifting up the car safely and releasing the parking brake cable on the Stanza Wagon (2WD). For the Stanza Wagon (4WD) stop removing the mounting nuts for transaxle support rod and control rod, front exhaust pipe at manifold, and transaxle flange before disengaging the shaft from transfer case. Loosen and take out the sway bar kit-to-transverse link mounting bolts using a wrench and being certain to fit the flats of the sway bar kit connecting rod when doing so. Bring the sway bar kit around the link and exhaust pipe; and to complete the operation you need to match the mark made earlier on the mark located in the mounting clamps, unscrew the bolts at the mounting clamps and then pull the bar out. The installation, in turn, is done in reverse order, particularly when mounting bolts are only to be tightened when the vehicle is on the ground and fully weighted on the wheels and proper positioning of the 'ball joint socket' of the sway bar kit.