×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 300ZX Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Flywheels found

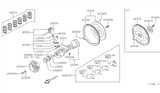

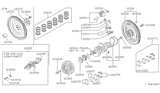

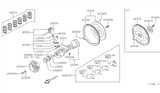

Nissan 300ZX Flywheel Assembly

Part Number: 12310-30P10$342.75 MSRP: $484.12Limited AvailabilityYou Save: $141.37 (30%)Nissan 300ZX Flywheel Assembly

Part Number: 12310-30P11$249.07 MSRP: $346.03Limited AvailabilityYou Save: $96.96 (29%)

Nissan 300ZX Flywheel

If you need any OEM Nissan 300ZX Flywheel, feel free to choose them out of our huge selection of genuine Nissan 300ZX Flywheel. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

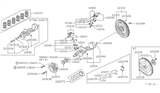

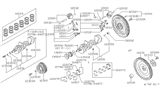

Nissan 300ZX Flywheel Parts Questions & Experts Answers

- Q: How do you properly remove and reinstall a flywheel on Nissan 300ZX?A:Raise the vehicle and support it securely on jackstands, then remove the pressure plate assembly and clutch disc. Use paint to make an alignment mark from the flywheel to the end of the crankshaft for reinstallation purposes. Remove the bolts securing the flywheel to the crankshaft rear flange; if difficulty arises due to crankshaft movement, wedge a screwdriver through the starter assembly opening to prevent the flywheel from turning. After removing the flywheel, clean any grease or oil from its surface and inspect for rivet grooves, burned areas, or scoring, correcting light scoring with emery cloth. Check for cracked or broken teeth and lay the flywheel on a flat surface to check for warpage. Clean the mating surfaces of the flywheel and crankshaft, then position the flywheel against the crankshaft, aligning it with the marks made during removal. Before installing the retaining bolts, apply a dab of sealing agent on the threads and tighten the bolts finger tight. Wedge a screwdriver through the starter motor opening to keep the flywheel from turning while tightening the bolts, and complete the installation by reversing the removal procedures.