×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 300ZX Wheel Bearing

Hub Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Wheel Bearings found

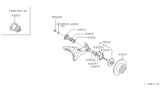

Nissan 300ZX Bearing Assembly Front WHELL

Part Number: 40210-33P07$79.35 MSRP: $114.92You Save: $35.57 (31%)Ships in 1-3 Business Days

Nissan 300ZX Bearing Axle

Part Number: 43210-21000$50.12 MSRP: $72.58You Save: $22.46 (31%)Ships in 1-3 Business Days

Nissan 300ZX BEARNG-Wheel

Part Number: 40215-A0100$44.48 MSRP: $61.32You Save: $16.84 (28%)Ships in 1-3 Business Days

Nissan 300ZX Bearing Assembly Front Wheel

Part Number: 40210-A0100$70.82 MSRP: $102.57You Save: $31.75 (31%)Ships in 1-3 Business Days

Nissan 300ZX Bearing Assy-Front Wheel

Part Number: 40210-33P02$79.35 MSRP: $114.92You Save: $35.57 (31%)

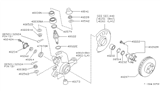

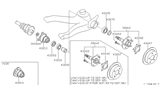

Nissan 300ZX Bearing-Rear (Axel Inner)

Part Number: 43210-35F06$279.13 MSRP: $394.25You Save: $115.12 (30%)

Nissan 300ZX Bearing-Rear (Axel Inner)

Part Number: 43210-35F01$279.13 MSRP: $394.25You Save: $115.12 (30%)Ships in 1-3 Business DaysNissan 300ZX Bearing-Rear Axle,Inner

Part Number: 43280-40P05$517.63 MSRP: $731.12You Save: $213.49 (30%)Ships in 1-3 Business DaysNissan 300ZX Bearing-Rear Axle,Inner

Part Number: 43281-40P05$394.12 MSRP: $557.00You Save: $162.88 (30%)Ships in 1-3 Business Days

Nissan 300ZX Wheel Bearing

If you need any OEM Nissan 300ZX Wheel Bearing, feel free to choose them out of our huge selection of genuine Nissan 300ZX Wheel Bearing. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

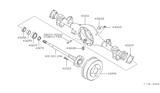

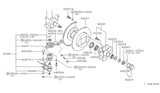

Nissan 300ZX Wheel Bearing Parts Questions & Experts Answers

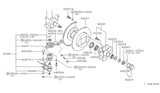

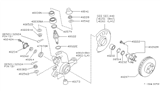

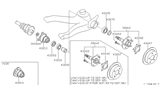

- Q: How do you properly replace and install wheel bearings and seals on Nissan 300ZX?A:Lift up the vehicle with the jack and firmly put it on jackstands, finally, take off the wheel. First, undo the bolts which hold the brake caliper on and then unscrew the dust cap and follow this by removing the O-ring. Remove the cotter pin and take the locking cap off of the wheel bearing nut on the wheel bearing. Lose the wheel bearing nut and washer on the spindle and unscrew the hub and the rotor; beware of the outside bearing falling off. Place the rotor in a face down manner on a work bench and then, with a screw driver, loosen the inner bearing grease seal to get its removal, together with the inner bearing. Scrape out all remnants of the old grease from the bearings, hub, as well as spindle before washing the area with parts solvent, check the condition of the bearings and if they show signs of wearing, replace them. If the bearing race is also worn or damaged, remove this also, with a brass drift for the bearing race out of the hub, and fit a new one together with the new bearing. Place a new race by using a socket to start screwing it into its seat with the addition of wheel bearings and bearing races being bought and installed as a set. To the bearings coat high-temperature front-wheel bearing grease and make sure that the grease is worked into the bearings completely. Apply a thin coat of grease to the spindle at various seats afterwards insert the inner bearing into the back of the hub and working a bit of grease. Apply some paste on the inner part of the seal lip, align the new seal over the inner bearing and push it and get it to be flush with the hub. Ensure that prior to the assembly of the hub into the spindle, the outer bearing carrying the grease pack is properly located and the hub before being fitted should be fully filled with grease. Place the washer with the adjuster nut, tightening it and rotating the rotor in clockwise & counter clockwise to press the bearings. After tightening the adjuster nut to the torque indicated earlier, turn the adjuster nut counterclockwise by sixty degrees to achieve the right pre-load. Replace the adjusting cap and use a new cotter pin, subsequently, use the dust cap with a new O-ring. Last of all, take of the jackstands and release the vehicle down.