×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 350Z Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Drive Belts found

Nissan 350Z Fan & Alternator Belt

Part Number: 11720-4P102$69.02 MSRP: $99.97You Save: $30.95 (31%)Ships in 1-2 Business Days

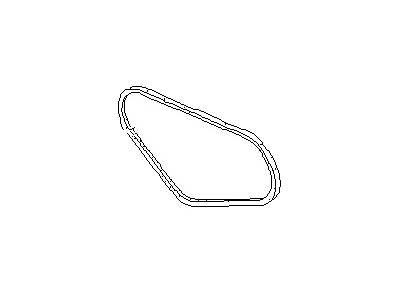

Nissan 350Z Compressor Belt

Part Number: 11920-AG900$38.59 MSRP: $55.90You Save: $17.31 (31%)Ships in 1-2 Business Days

Nissan 350Z Fan & Alternator Belt

Part Number: 11720-JK20A$65.12 MSRP: $94.32You Save: $29.20 (31%)Ships in 1-2 Business Days

Nissan 350Z Fan & Alternator Belt

Part Number: 11720-4P10A$74.20 MSRP: $107.47You Save: $33.27 (31%)Ships in 1-3 Business DaysNissan 350Z Fan & Alternator Belt

Part Number: 11720-4P110$69.02 MSRP: $99.97You Save: $30.95 (31%)Ships in 1 Business Day

Nissan 350Z Drive Belt

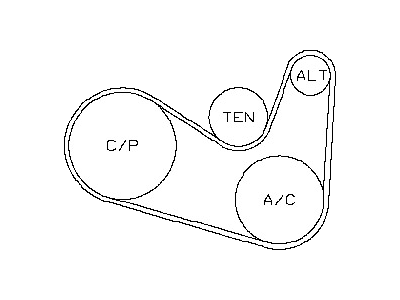

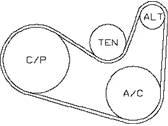

The Nissan 350Z Drive Belt is one of the highly important parts that play the key role for the car's solid work. This serpentine Drive Belt links the engine to other parts in the automobile including the alternator and the A/C compressor for efficiency in power transmission. The Nissan 350Z Drive Belt has a typical service life of about 100,000 miles, however, fresh replacement is significant for high-performance cars to avoid severe damage to the car engine. Applicable to the Nissan 350Z's standard model, the enthusiast, and the performance model, this Drive Belt increases the car's efficiency and security factors. It has a versatile outlook that enables it to hold many parts at a go, and thus need to operate them efficiently is very important for the performance of the engine. The Nissan 350Z Drive Belt sets the car apart in the market because of its long lasting and flexible quality that will perform well in spirited activities for the car owners. Moreover, it is also essential in the 350Z versions because of the Drive Belt's compatibility with the VQ35DE and VQ35HR high-output engines. In conclusion, the Nissan 350Z Drive Belt is a fine representation of Nissan's quality and performance vehicles and thus recommended for any car lover, be it for a hobby or a daily driver.

If you need any OEM Nissan 350Z Drive Belt, feel free to choose them out of our huge selection of genuine Nissan 350Z Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 350Z Drive Belt Parts Questions & Experts Answers

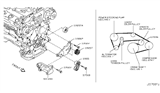

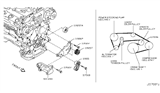

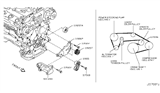

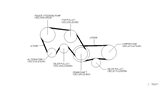

- Q: What is the importance of drivebelts in engine operation and how should they be inspected and maintained on Nissan 350Z?A:The drivebelts are located at the front of the engine, and it is imperative that they are in good condition and properly adjusted to ensure proper operation of the engine. With time drivebelts stretch, wear out due to their composition and high stress they work under, hence need to be inspected periodically. One belt powers the alternator as well as power steering while the other transmits force from the crankshaft to the air conditioning compressor. When the engine stops running, open its hood to locate drive belts at its front end. Examine each belt for different signs of wear-if any is found, replace it. Belt tension is determined by pushing on a belt at a point half-way between pulleys. Loosen a locking nut when it is necessary to adjust a belt then turn an adjusting bolt and measure the tension in a belt before repeating until a drivebelt is adjusted. To replace a belt, raise vehicle and secure it safely on jackstands, remove engine splash shield then proceed to recalibrate drivebelt by following recommended procedures. First remove power steering pump belt if there is need for replacing air conditioner compressor belt . It may be wise to replace both belts together and mark each one so that they fit into their respective grooves perfectly while ensuring that they are always aligned with correct pulleys. Take them with you when you go shopping so that you can compare them directly with others in terms of length width or design style. After fitting a new drivebelt ensure that it fits snugly into ribbed grooves on the pulleys and remains centrally placed. Adjust this/those belt(s) according to steps already given above.