×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

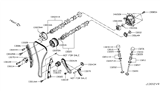

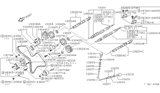

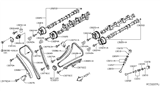

Genuine Nissan Altima Valve Stem Oil Seal

Engine Valve Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Valve Stem Oil Seals found

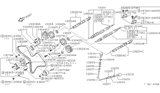

Nissan Altima Seal-Oil,Valve

Part Number: 13207-84A00$6.92 MSRP: $9.53You Save: $2.61 (28%)Ships in 1-2 Business Days

Nissan Altima Seal Valve

Part Number: 13207-2B500$5.44 MSRP: $7.50You Save: $2.06 (28%)Ships in 1-2 Business Days

Nissan Altima Seal-Lip Valve

Part Number: 13207-3Z00A$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Altima Seal-Oil,Valve

Part Number: 13207-3Z000$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Altima Seal Valve

Part Number: 13207-53F00$5.31 MSRP: $7.50You Save: $2.19 (30%)Ships in 1-2 Business Days

Nissan Altima Seal-Oil,Valve

Part Number: 13207-D4201$6.75 MSRP: $9.53You Save: $2.78 (30%)Ships in 1-2 Business Days

Nissan Altima Seal-Lip Valve

Part Number: 13207-00Q0A$2.87 MSRP: $3.95You Save: $1.08 (28%)Ships in 1-2 Business DaysNissan Altima Seal-Lip Valve

Part Number: 13207-ET00A$5.83 MSRP: $8.03You Save: $2.20 (28%)Ships in 1-3 Business DaysNissan Altima Seal-Oil,Valve

Part Number: 13207-5NA0C$5.32 MSRP: $7.33You Save: $2.01 (28%)Ships in 1-3 Business Days

Nissan Altima Valve Stem Oil Seal

If you need any OEM Nissan Altima Valve Stem Oil Seal, feel free to choose them out of our huge selection of genuine Nissan Altima Valve Stem Oil Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Altima Valve Stem Oil Seal Parts Questions & Experts Answers

- Q: How can broken valve springs and defective valve stem seals be replaced without removing the cylinder head on 4 cylinder Nissan Altima?A:Valve springs, in particular, those which are broken, and valve stem seals, which are faulty, can be replaced during the course of avoiding the removal of the Cylinder Head; this requires generally two special tools and a source of compressed air. Waiting for the cylinder head on a stable bench, utilize the big and large clamp type of valve spring compressor and adapter where the bottom part of the tool should be resting beneath the working valve and to compress accordingly until the keepers can be easily removed with the help of magnet or small pliers. Extract the valve spring along with the retainer, to eliminate it, undo the old valve stem oil seal using pliers. Run the valve stem in the guide and using your fingers see whether it wobbles; this is an indication that the valve is bent. Rock the valve back and forth in the guide and look for binding; if there is binding then the valve maybe bent or the guide may be damaged and this means further procedures of cylinder head repair. Apply a coat of engine oil on the valve stem and then fasten the valve spool into the cylinder head, placing a piece of plastic container seal guard on the valve stem to avoid tearing of the new seal. If there is no seal protector, wind the cellulose tape around the valve stem of the faucet . With the multi-purpose grease provided, immerse the new seal and push it downwards over the valve stem; the protector or tape should be withdrawn when the seal hits the guide. Place the new seal into the deep socket appropriate for the diameter and gently tap it down to the top of the valve guide, then put the spring into proper place over the valve with the retainer. Next, co sam Main spring of the valve and its retainer; use the keepers to fit the spring in the grooves and if it is needed a small amount of the grease must be applied in order for the keepers to be stayed in place and properly fixed; the keepers should be inserted with the needle-nose pliers. Release pressure with the use of spring tool while confirming that the keepers are in place. Replace the lifters and camshafts, and finish the procedure in a sequence that is the reversal of that implemented during removal. Switch on the engine and observe its performance and the extent of oil leakage and strange noises originating from the region of the valve cover.

Related Nissan Altima Parts

Browse by Year

2025 Valve Stem Oil Seal 2024 Valve Stem Oil Seal 2023 Valve Stem Oil Seal 2022 Valve Stem Oil Seal 2021 Valve Stem Oil Seal 2020 Valve Stem Oil Seal 2019 Valve Stem Oil Seal 2018 Valve Stem Oil Seal 2017 Valve Stem Oil Seal 2016 Valve Stem Oil Seal 2015 Valve Stem Oil Seal 2014 Valve Stem Oil Seal 2013 Valve Stem Oil Seal 2012 Valve Stem Oil Seal 2011 Valve Stem Oil Seal 2010 Valve Stem Oil Seal 2009 Valve Stem Oil Seal 2008 Valve Stem Oil Seal 2007 Valve Stem Oil Seal 2006 Valve Stem Oil Seal 2005 Valve Stem Oil Seal 2004 Valve Stem Oil Seal 2003 Valve Stem Oil Seal 2002 Valve Stem Oil Seal 2001 Valve Stem Oil Seal 2000 Valve Stem Oil Seal 1999 Valve Stem Oil Seal 1998 Valve Stem Oil Seal 1997 Valve Stem Oil Seal 1996 Valve Stem Oil Seal 1995 Valve Stem Oil Seal 1994 Valve Stem Oil Seal 1993 Valve Stem Oil Seal