×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

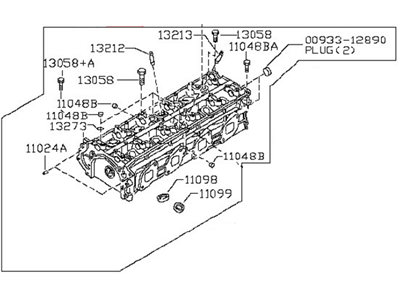

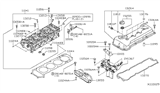

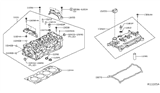

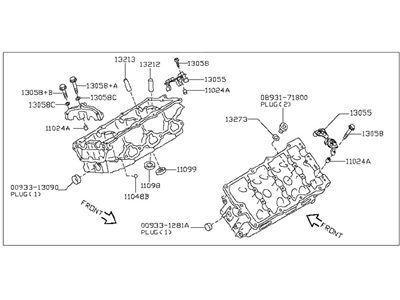

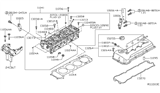

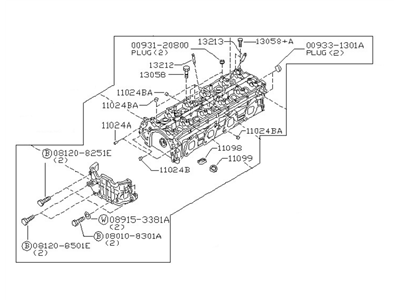

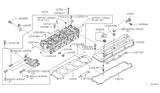

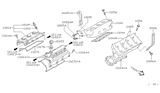

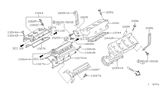

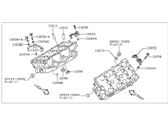

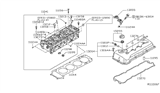

Genuine Nissan Altima Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Cylinder Heads found

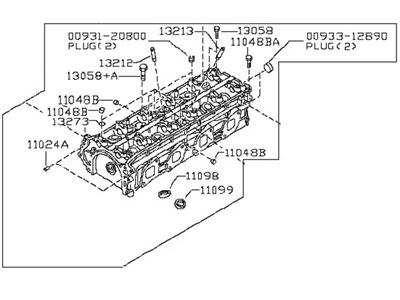

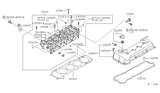

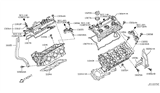

Nissan Altima Cylinder Head

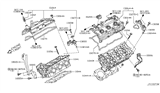

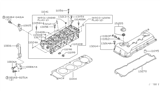

Part Number: 11040-3TA2A$932.77 MSRP: $1317.47You Save: $384.70 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head

Part Number: 11040-3TA0A$932.77 MSRP: $1317.47You Save: $384.70 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-JA00A$1275.73 MSRP: $1617.03You Save: $341.30 (22%)Ships in 1-2 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-4GA0A$1209.33 MSRP: $1464.09You Save: $254.76 (18%)Ships in 1-3 Business DaysNissan Altima Head Assy-Cylinder,LH

Part Number: 11090-4GA0A$1450.11 MSRP: $1755.59You Save: $305.48 (18%)Ships in 1-3 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-EA200$2178.59 MSRP: $2637.51You Save: $458.92 (18%)Ships in 1-3 Business DaysNissan Altima Head Assembly-Cylinder,L

Part Number: 11090-EA200$3570.79 MSRP: $4322.99You Save: $752.20 (18%)Ships in 1-3 Business DaysNissan Altima Cylinder Head

Part Number: 11040-6CA1A$798.47 MSRP: $1127.78You Save: $329.31 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-5NA0B$1092.00 MSRP: $1542.37You Save: $450.37 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head

Part Number: 11040-5NA0C$1092.00 MSRP: $1542.37You Save: $450.37 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-8H301$764.32 MSRP: $996.51Limited AvailabilityYou Save: $232.19 (24%)Nissan Altima Head Assy-Cylinder,LH

Part Number: 11090-JA10A$1930.57 MSRP: $2337.26You Save: $406.69 (18%)Ships in 1-3 Business DaysNissan Altima Cylinder Head Assembly

Part Number: 11040-JA10A$2030.78 MSRP: $2458.57You Save: $427.79 (18%)Ships in 1-3 Business DaysNissan Altima Cylinder Head

Part Number: 11040-6CA0A$798.47 MSRP: $1127.78You Save: $329.31 (30%)Ships in 1-3 Business DaysNissan Altima Cylinder Head

Part Number: 11040-9E000$1349.51 MSRP: $1759.46Limited AvailabilityYou Save: $409.95 (24%)Nissan Altima Cylinder Head Assembly

Part Number: 11040-9J000$1460.45 MSRP: $1904.11Limited AvailabilityYou Save: $443.66 (24%)Nissan Altima Head Assembly-Cylinder,L

Part Number: 11090-9J000$1866.18 MSRP: $2259.30Limited AvailabilityYou Save: $393.12 (18%)

| Page 1 of 2 |Next >

1-20 of 26 Results

Nissan Altima Cylinder Head

If you need any OEM Nissan Altima Cylinder Head, feel free to choose them out of our huge selection of genuine Nissan Altima Cylinder Head. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Altima Cylinder Head Parts Questions & Experts Answers

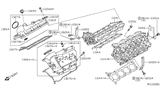

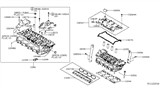

- Q: How to remove and install a cylinder head on 4 cylinder Nissan Altima?A:Before removing of the cylinder head first take off the pressure from the fuel system make the engine ready for TDC compression in cylinder no. 1 and match off the connection wire from negative terminal of battery. Remove the coolant, detract the Timing Chain, cam shaft, Exhaust Manifold and Intake Manifold. Unlike the specific items that were added on the next step, information related to the cylinder head should state that all the G-Particles which are related to coolant fitting, tubes, cables, hoses or wiring harnesses should be labeled and detached. The cylinder head bolt or screw fastener should be loosened by 1/4 turn each time and finally removed by the hand, if you are using a breaker bar and the hex bit and uniformly applying its torque then the desired result can be obtained without warping or cracking of the cylinder head utilising the reverse order of the sequence in which the bolts were tightened. In this process, raise the cylinder head off the engine block, especially if it is lodged in place and then, remove all the external structures for thorough washing and examining. Regarding installation, the mating surfaces for the cylinder head and block should be absolutely pure, using a gasket scraper and cleaning agents to clear off carbon and old gasket substances. Clean the components' mating surfaces; use a fine file for minor splines and consider machining for major splines. Thread the threads that are in the cylinder head bolt holes with the use of a tap and vacuum clean the same. Following this, make sure that the gasket surface of the cylinder head is clean and that the head is not warped and replace any part that you may have been compelled to uninstall. Place the new cylinder head gasket over the dowel pins at the block and then fit the cylinder head carefully over the block with no effecting the position of the gasket. It is recommended to drip a little of clean engine oil over the threaded and hardened washers of the new cylinder head bolts, while the chamfered side of the washers should face the bolt heads. Replacing the cylinder head bolts with new ones, and tighten these bolts with proper sequence and to the prescribed torque. Insatll the lifters and the camshafts follow by the timing chain, and then finally check the valve clearances. The remaining installation steps are the exact opposite of the removal process of the corresponding program. The cooling system should be refilled, a new oil filter should be put in, and oil should be added to the engine and battery reconnected as needed along with any re learn steps that may need to be carried out.

Related Nissan Altima Parts

Browse by Year

2025 Cylinder Head 2024 Cylinder Head 2023 Cylinder Head 2022 Cylinder Head 2021 Cylinder Head 2020 Cylinder Head 2019 Cylinder Head 2018 Cylinder Head 2017 Cylinder Head 2016 Cylinder Head 2015 Cylinder Head 2014 Cylinder Head 2013 Cylinder Head 2012 Cylinder Head 2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head