×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Frontier Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

82 Pistons found

Nissan Frontier Piston,W/Pin

Part Number: 12010-EA200$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-9BP0C$52.66 MSRP: $72.60You Save: $19.94 (28%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-EA20B$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1 Business DayNissan Frontier Piston W/Pin

Part Number: 12010-EA21B$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-9BP2C$43.45 MSRP: $59.90You Save: $16.45 (28%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-9BP0D$58.33 MSRP: $80.42You Save: $22.09 (28%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA01C$80.43 MSRP: $113.60You Save: $33.17 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA02C$81.23 MSRP: $114.73You Save: $33.50 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA09C$82.23 MSRP: $116.15You Save: $33.92 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-EA22B$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: 12010-9BP1C$46.06 MSRP: $63.50You Save: $17.44 (28%)Ships in 1-3 Business DaysNissan Frontier Piston,W/Pin

Part Number: 12010-EA201$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/PIN (O/S)

Part Number: 12010-EA071$51.99 MSRP: $71.67You Save: $19.68 (28%)Ships in 1-3 Business DaysNissan Frontier Piston,W/Pin

Part Number: 12010-EA202$94.26 MSRP: $133.13You Save: $38.87 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-1Z111$51.99 MSRP: $71.67Limited AvailabilityYou Save: $19.68 (28%)Nissan Frontier Piston W/Pin

Part Number: A2010-8Z310$64.29 MSRP: $90.80You Save: $26.51 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-1Z110$64.29 MSRP: $90.80You Save: $26.51 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA01A$80.43 MSRP: $113.60You Save: $33.17 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA02A$81.23 MSRP: $114.73You Save: $33.50 (30%)Ships in 1-3 Business DaysNissan Frontier Piston W/Pin

Part Number: A2010-EA09A$82.23 MSRP: $116.15You Save: $33.92 (30%)Ships in 1-3 Business Days

| Page 1 of 5 |Next >

1-20 of 82 Results

Nissan Frontier Piston

If you need any OEM Nissan Frontier Piston, feel free to choose them out of our huge selection of genuine Nissan Frontier Piston. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Frontier Piston Parts Questions & Experts Answers

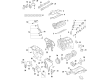

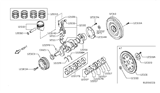

- Q: How to install piston/connect rod assemblies on Nissan Frontier?A:So, before you start putting the piston/rod assemblies in place, make sure that cylinder walls are clean enough, the top edges of all cylinders are chamfered and the Crankshaft is installed. First, take off the cap at the end of number one connecting rod. Just get rid of old bearing inserts and thoroughly clean both rod and cap bearing surfaces with a soft cloth that is perfectly clean and free from fluff. Clean the backside of upper insert that's new for connecting rod bearing oil clearance check, fit it into the rod ensuring its tab aligns with hole at recess backside. Do this for another insert and the rod cap, taking good care to protect their faces from any oil or dirt contamination. Carefully place the piston rings as specified around the piston and lubricate them with fresh engine oil. Affix a piston ring compressor to hold compression as you guide it into position in the cylinder with skirt sticking out slightly. Rotate crankshaft until number one connecting rod journal reaches bottom dead center (BDC) and then apply oil on cylinder walls. The notch in pistons should face toward other end of engine behind belt or chain drive when inserting piston/connecting rod assembly into number one cylinder bore using gentle tapping motion onto crankshaft journal. Always keep rings compressed during this process; do not force piston if it is stubborn going through dead center. Finally, there should be a similar examination for connecting rod bearing oil clearance by placing Plastigage on number one connecting rod journal then installing rod cap without disturbing Plastigage in case something goes wrong because Plastigage has been removed carefully without harm to any part of the engine or other components involved in its operation which will require complete overhaul sooner rather than later due to failure caused by lack maintenance practices depending on how long it took since last service was done but sometimes engineers can make mistakes even unintentionally such as leaving some leftover material inside their cars after assembling them hence leading catastrophic consequences if not attended time by qualified technicians. As you tighten nuts, use a lightweight socket and do not turn the crankshaft. Gently unfasten rod cap verifying oil clearance matches given specifications with reference to width of crushed Plastigage as seen on envelope. Otherwise, check out various bearing inserts after confirming cleanliness and journal diameter. Remove all Plastigage material then apply clean moly-base grease/ engine assembly lube to bearing faces and reinstall rod cap. Repeat the same process for the other pistons/connecting rods ensuring cleanliness, correct assembly, correct "W" mark position and lubrication as required. Hand-rotate the crankshaft after all these assemblies have been installed for binding purposes. Finally, check connecting rod endplay against specifications and take necessary steps if endplay is wrong such as resizing or replacing rods should be done when it is not sufficient/excessive according to allowable range specified in given service manual by manufacturer of your particular vehicle/motorcycle model which can be obtained through authorized dealerships or directly from their websites depending on where you reside within continental United States (CONUS).

Related Nissan Frontier Parts

Browse by Year

2024 Piston 2023 Piston 2022 Piston 2021 Piston 2020 Piston 2019 Piston 2018 Piston 2017 Piston 2016 Piston 2015 Piston 2014 Piston 2013 Piston 2012 Piston 2011 Piston 2010 Piston 2009 Piston 2008 Piston 2007 Piston 2006 Piston 2005 Piston 2004 Piston 2003 Piston 2002 Piston 2001 Piston 2000 Piston 1999 Piston 1998 Piston