×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

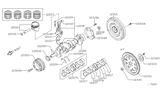

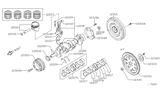

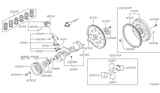

Genuine Nissan Frontier Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Crankshafts found

Nissan Frontier Crankshaft Assembly

Part Number: 12200-EA200$1026.43 MSRP: $1449.77You Save: $423.34 (30%)Ships in 1-3 Business Days

Nissan Frontier CANKSHAFT Assembly

Part Number: 12201-JA02A$1302.87 MSRP: $1577.33You Save: $274.46 (18%)Ships in 1-3 Business DaysNissan Frontier Crankshaft Assembly

Part Number: 12201-9BT0A$862.52 MSRP: $1218.25You Save: $355.73 (30%)Ships in 1-3 Business DaysNissan Frontier Crankshaft Assembly

Part Number: 12201-3TA0A$1302.87 MSRP: $1577.33You Save: $274.46 (18%)Ships in 1-3 Business DaysNissan Frontier Crankshaft Assembly

Part Number: 12200-9BF0A$1026.43 MSRP: $1449.77You Save: $423.34 (30%)Nissan Frontier Crankshaft Assembly

Part Number: 12201-JA03A$1302.87 MSRP: $1577.33You Save: $274.46 (18%)Ships in 1-3 Business Days

Nissan Frontier Crankshaft

If you need any OEM Nissan Frontier Crankshaft, feel free to choose them out of our huge selection of genuine Nissan Frontier Crankshaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

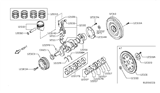

Nissan Frontier Crankshaft Parts Questions & Experts Answers

- Q: How to remove the crankshaft on Nissan Frontier?A:Crankshaft removal is a process that can only happen after the engine has been removed from the vehicle and involves some prerequisites, like taking off the flywheel/driveplate, crankshaft pulley, timing belt (for 3.3L engines) or timing chain (for 2.4L and 3.5L engines), camshaft, crankshaft sprockets, oil pan, oil pump, and piston/connecting rod assemblies. In addition to this, before one embarks on crankshaft removal, it is important to examine the endplay of the crankshaft using dial indicators or feeler gauges. The dial indicator should be mounted with the stem in line with the crankshaft to contact one of its throws and zeroed out. After that, gently push back the crankshaft and observe the reading given by a dial indicator as this will indicate endplay. If there are excessive side clearances in excess of specifications then an investigation into wear on thrust surface of the crankshaft is required. If no wear is indicated then replacement of main bearing may cure end play problem. An alternative way to measure crankshaft end play uses feeler gauges to pry or push gently against the front face of the thrust bearing while placing feeler gauges between it and the front of the thrust bearing to determine how much clearance exists. Gradually loosen each main bearing cap bolt by turning it a quarter turn at a time in reverse order of tightening them until manoully removable bearing cap(s) and brace assembly are achieved.Normally cast-in arrows on main bear ing cap assembly indicate direction towards drivebelt end of engine but if these aren't there use number stamp or punch for marking cap assembly position/direction. Only mark front side of bearing cap brace when working on 3.3L engines because caps and brace are asingle unit.On 3.5L engines however, front part of bearing cap brace should be marked, removed and then inspected for installation marks on main bearing caps before they are removed from the engine. Notably, 2.4L engines do not include a main bearing cap brace. Theoretically, when loosening cap assembly from the engine block, you should be careful about losing bearing inserts in case they come out with the cap assembly. Thereafter, lift crankshaft out of the engine being cautious about its significant weight by preferably using help. Finally, put back cap assembly at its position ontheengineblockwiththebearinginsertsintactandtightenboltsfinger-tight.Incaseof3.5Lengines,the condition of main bearing cap bolts must be checked to ensure that there is no excessive stretching; if there is a difference of more than 0.0043 inch (0.11 mm) between indicated areas in bolt diameter, replace the bolts even complete sets if necessary.

Related Nissan Frontier Parts

Browse by Year

2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft