×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Juke Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Transmission Assemblies found

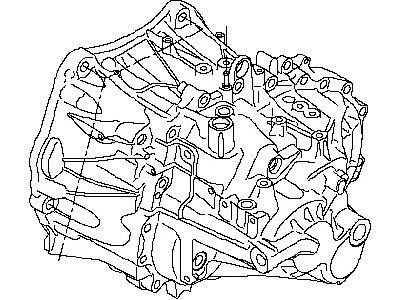

Nissan Juke Manual Transaxle

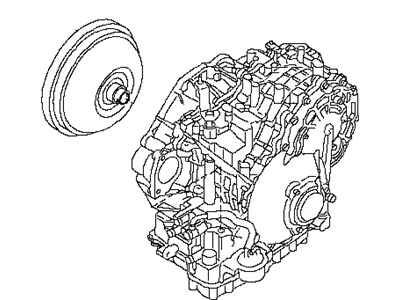

Part Number: 32010-00Q3P$2919.72 MSRP: $3534.77You Save: $615.05 (18%)Ships in 1-3 Business DaysNissan Juke Automatic Transaxle

Part Number: 31020-3VX4D$2903.93 MSRP: $3515.66You Save: $611.73 (18%)Ships in 1-3 Business DaysNissan Juke Manual Transaxle

Part Number: 32010-3YW0D$3358.27 MSRP: $4065.70You Save: $707.43 (18%)Ships in 1-3 Business DaysNissan Juke Manual Transaxle

Part Number: 320B0-00QAA$3443.65 MSRP: $4065.70You Save: $622.05 (16%)Ships in 1-2 Business DaysNissan Juke Automatic Transaxle

Part Number: 31020-3VX6D$2903.93 MSRP: $3515.66You Save: $611.73 (18%)Ships in 1-3 Business DaysNissan Juke Automatic Transmission Assembly

Part Number: 31020-3TX0A$2842.33 MSRP: $3441.07You Save: $598.74 (18%)Ships in 1-3 Business DaysNissan Juke Manual Transmission Assembly

Part Number: 32010-1KG0A$3358.27 MSRP: $4065.70You Save: $707.43 (18%)Ships in 1-3 Business DaysNissan Juke Automatic Transmission Assembly

Part Number: 310C0-3TX0C$2377.70 MSRP: $2878.57You Save: $500.87 (18%)Nissan Juke Automatic Transmission Assembly

Part Number: 31020-3TX0C$2915.73 MSRP: $3529.94You Save: $614.21 (18%)

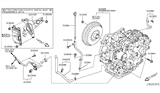

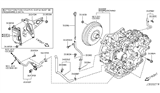

Nissan Juke Transmission Assembly

If you need any OEM Nissan Juke Transmission Assembly, feel free to choose them out of our huge selection of genuine Nissan Juke Transmission Assembly. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Juke Transmission Assembly Parts Questions & Experts Answers

- Q: How do you properly remove and refit the transmission assembly on Nissan Juke?A:The engine can stay in the car while removing the gearbox, or else both the engine and gearbox can be removed together and separated later on. It is recommended that when removing the transmission, replace the clutch slave cylinder so as to prevent leakage of fluid. The transmission model code number can be found on a label located on top of the transmission housing. Begin lifting up the front of the vehicle by applying handbrake and jacking up its front. Remove both frontal roadwheels and offside front wheel arch liner. Drain oil from gearbox into a suitable container then refit drain and filler/level plugs. Remove battery, battery tray, air cleaner assembly, starter motor, and exhaust front pipe. Let gearchange cables go slack and release front suspension subframe. Be careful to adequately hold up two foredriveshafts from gearbox. Disconnect earth lead, wiring connector from reversing light switch, and crankshaft position sensor. Disconnect slave cylinder connector pipe from hydraulic pipe and plug it at each end to stop leakage of fluid. Free harnessing loom from any retaining clips so that it is clear of transmission. See to it that breather hose on top of gearbox case is not secured to any other part(s). Get rid of rear engine mounting bracket/arm link connected to torque tube joint (aluminium). Use hoists or jacks to lift engine & box assembly into position. Take off lefmotor/gearbox mount plus mounting plate above box-top cover at any given time thereafter. Unscrew remaining nuts fixing gear box house to engine block; pay attention to their positions order during disassembly process. If necessary raise box slightly for lower bolts access. Ensure all necessary components are disconnected from gear box before moving it out with jack. Slide jack away towards left side so as to unhook it partly from locating dowels; then lower jack to remove gearbox from under the vehicle. Remove locating dowels if loose and keep them in safe place. To refit, follow the reverse of the removal procedure. After removal, replace concentric clutch slave cylinder, apply a small amount of high temperature grease to input shaft splines on gearbox, make sure locating dowels are properly positioned inside bell housing, install transmission-to-engine bolts into their original locations, and torque all nuts and bolts to specified values. Fit back driveshafts etc., front strut assembly and bleed hydraulic clutch system. Lastly, reinstall gearchange cables and test their operation; then refill transmission with prescribed oil grade.