×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

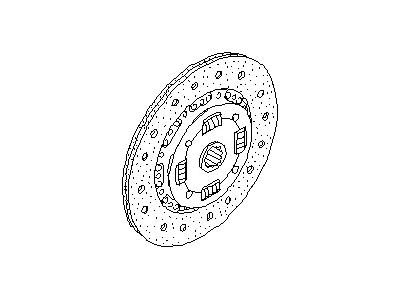

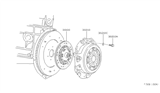

Genuine Nissan Maxima Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Clutch Discs found

Nissan Maxima Clutch Disc Assembly

Part Number: 30100-7Y010$175.50 MSRP: $247.88You Save: $72.38 (30%)

Nissan Maxima Clutch Disc

If you need any OEM Nissan Maxima Clutch Disc, feel free to choose them out of our huge selection of genuine Nissan Maxima Clutch Disc. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Maxima Clutch Disc Parts Questions & Experts Answers

- Q: How to remove and inspect the Pressure Plate and Clutch Disc on Nissan Maxima?A:To get at the clutch components, it is normal to eliminate the transaxle while the engine remains installed in the car. When the engine is being replaced due to major overhaul, it is also important check the clutch for tear and replace any of the following as the cost of clutch parts are relatively cheaper than the time it would take to replace them especially when they are located in deep parts of the vehicle. When the engine is left in place it is necessary to pull the transaxle which in turn requires that the engine be properly supported either by jack or an engine lift or support frame. If using a jack place a piece of wood between the jack and oil pan since the pickup for the oil pump is almost near the bottom of the oil pan. The release fork and bearing can be left connected to this transaxle but they must be checked at the time of removal. Thus, a clutch alignment tool should be installed through the disc hub in order to support the clutch disc. When ordering the replacement parts, the flywheel and pressure plate should have indexing marks, and if they don't you need to make your own so they will be placed back in the same position. Nuts on pressure plate to flywheel bolts must be loosened in a criss-cross fashion to release all spring pressure then remove the bolt, pressure plate both the clutch disc and the pilot bearing can be stuck on to a slide hammer. It is also recommended to inspect the fly wheel for crack and any signs of damages; in that case, it can be machined. The clutch disc lining must be of at least 1/16-inch above the rivet heads, and if there are signs of wearing out then it has to be changed. It is also recommended that the release bearing should be changed together with the clutch disc. With a probe, feel for any wear and tear of the pressure plate, if any, remove and replace it. When installing the clutch disc and pressure plate, with the help of an alignment tool turn the things into the right place and use bolts to fasten the pressure plate while also tightening the bolts in a criss-cross manner. Once the bolts are properly tightened, again, measure the torque on them and then remove the alignment tool. Grease the release bearing and put it back to its place, the transaxle together with all other components that were removed should be reinstalled, and all the bolts tightened to correct torque.

Related Nissan Maxima Parts

Browse by Year

2007 Clutch Disc 2006 Clutch Disc 2005 Clutch Disc 2004 Clutch Disc 2003 Clutch Disc 2002 Clutch Disc 2001 Clutch Disc 2000 Clutch Disc 1999 Clutch Disc 1998 Clutch Disc 1997 Clutch Disc 1996 Clutch Disc 1995 Clutch Disc 1994 Clutch Disc 1993 Clutch Disc 1992 Clutch Disc 1991 Clutch Disc 1990 Clutch Disc 1989 Clutch Disc 1988 Clutch Disc 1987 Clutch Disc 1986 Clutch Disc 1985 Clutch Disc