×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Maxima Lash Adjuster

Lash Adjuster Lifter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

139 Lash Adjusters found

Nissan Maxima Lifter-Valve

Part Number: 13231-V5014$212.03 MSRP: $299.48You Save: $87.45 (30%)Ships in 1-3 Business Days

Nissan Maxima Lifter-Valve

Part Number: 13231-2Y810$54.07 MSRP: $74.53You Save: $20.46 (28%)Ships in 1-3 Business Days

Nissan Maxima Lifter-Valve

Part Number: 13231-2Y871$55.11 MSRP: $75.97You Save: $20.86 (28%)Ships in 1-2 Business Days

Nissan Maxima Lifter-Valve

Part Number: 13231-7S018$55.11 MSRP: $75.97You Save: $20.86 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-JA10A$28.29 MSRP: $39.00You Save: $10.71 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-2Y818$55.11 MSRP: $75.97You Save: $20.86 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-2Y873$55.95 MSRP: $77.13You Save: $21.18 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-9HP0B$26.95 MSRP: $37.15You Save: $10.20 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-AR010$33.36 MSRP: $45.98You Save: $12.62 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-2Y812$54.07 MSRP: $74.53You Save: $20.46 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-7S020$54.10 MSRP: $74.58You Save: $20.48 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-4W001$54.10 MSRP: $74.58You Save: $20.48 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-9HP2C$27.48 MSRP: $37.88You Save: $10.40 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-2Y802$52.39 MSRP: $72.22You Save: $19.83 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-7S021$54.90 MSRP: $75.68You Save: $20.78 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-7S016$55.95 MSRP: $77.13You Save: $21.18 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-9HP1E$26.56 MSRP: $36.62You Save: $10.06 (28%)Ships in 1-3 Business DaysNissan Maxima Lifter-Valve

Part Number: 13231-9HP1A$27.48 MSRP: $37.88You Save: $10.40 (28%)Ships in 1-3 Business Days

| Page 1 of 7 |Next >

1-20 of 139 Results

Nissan Maxima Lash Adjuster

If you need any OEM Nissan Maxima Lash Adjuster, feel free to choose them out of our huge selection of genuine Nissan Maxima Lash Adjuster. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

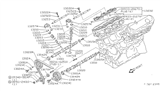

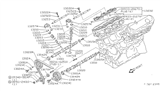

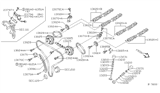

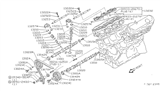

Nissan Maxima Lash Adjuster Parts Questions & Experts Answers

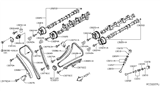

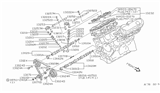

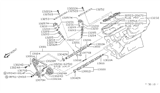

- Q: How do you remove and install lifters camshaft seal and a camshaft on Nissan Maxima SOHC?A:In order to drop the Lash Adjusters, it will be necessary to firstly take off the valve cover and the rocker arm shafts. Tighten secured the Lash Adjusters by lifting them up and placing a rubber band around each of them so that they don't come off the guides; if a Lash Adjuster is found off, put it back to its place. Subsequently, unbolt the Lash Adjuster guide assembly and pull out the Lash Adjusters out of the bores individually with the help of a pick and ensure that the Lash Adjusters are put back in the same manner as they were taken out. Do not lay the Lash Adjusters on their side or upside down as this increases the trap of air; they can only be laid on their side if they are submerged in clean engine oil. Place the tip of your finger on the plunger button, while the Lash Adjuster is in its bore, push up the plunger; if it moves more than 0.040-inch (1 mm) you may have trapped some air inside. If air is suspected, return the rocker arm shaft assemblies and valve cover, then tap on the Lash Adjusters until all the air is out of the Lash Adjusters by starting the engine under no load and letting idle for about 10 minutes with revs at 1000 rpm. After that, the valve cover and the rocker arm shaft assemblies have to be removed, and the plunger check has to be done one more time. If air remains, replace the Lash Adjuster with a new one. When the Lash Adjusters are out check for wear and during positioning, apply clean engine oil on each of the Lash Adjusters. To remove the camshaft, first, lose the cylinder heads and then use the camshaft cover plate bolts and remove the other one carefully at the transaxle side. Position holding lugs on the camshaft to prevent it from rotating as the retaining bolt is loosened to follow by the removal of the bolt and thrust plate. Carefully take out the camshaft oil seal without causing any doze on your camshaft and pull the camshaft by twisting it. To install, use moly-based engine assembly lube to the camshaft bearing journals and the lobes and then gently Vladimire the camshaft in the cylinder head. Place the thrust plate with the retaining bolt and fasten it to the required torque to check the end play of the camshaft; if the amount is higher than the recommended limit, then change the thrust plate. Last, replace the camshaft oil seal, while other parts of the cylinder head assembly should be put back in the reverse of the process of removal. Depending on what is being done, the camshaft seals can be replaced in-car provided the Timing Belt and camshaft sprockets are removed; special care should be taken not to harm the camshaft journal. It is recommended to use a seal installation tool or a proper diameter of pipe to force the new seal straightly into the cylinder head while seated.

Related Nissan Maxima Parts

Browse by Year

2023 Lash Adjuster 2022 Lash Adjuster 2021 Lash Adjuster 2020 Lash Adjuster 2019 Lash Adjuster 2018 Lash Adjuster 2017 Lash Adjuster 2016 Lash Adjuster 2014 Lash Adjuster 2013 Lash Adjuster 2012 Lash Adjuster 2011 Lash Adjuster 2010 Lash Adjuster 2009 Lash Adjuster 2008 Lash Adjuster 2007 Lash Adjuster 2006 Lash Adjuster 2005 Lash Adjuster 2004 Lash Adjuster 2003 Lash Adjuster 2002 Lash Adjuster 2001 Lash Adjuster 2000 Lash Adjuster 1999 Lash Adjuster 1998 Lash Adjuster 1997 Lash Adjuster 1996 Lash Adjuster 1995 Lash Adjuster 1994 Lash Adjuster 1993 Lash Adjuster 1992 Lash Adjuster 1991 Lash Adjuster 1990 Lash Adjuster 1989 Lash Adjuster 1988 Lash Adjuster 1987 Lash Adjuster 1986 Lash Adjuster 1985 Lash Adjuster