×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

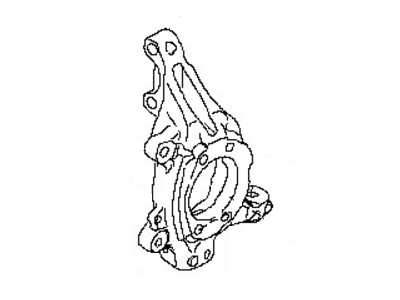

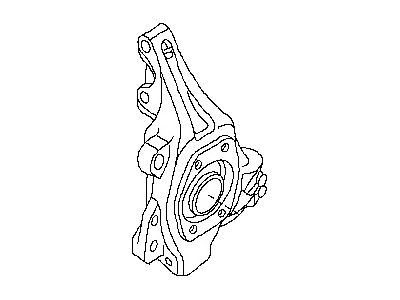

Genuine Nissan Murano Steering Knuckle

Front Steering Knuckle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Steering Knuckles found

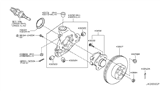

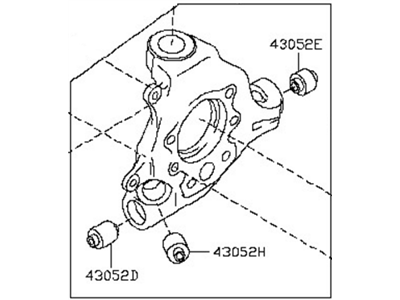

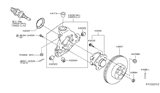

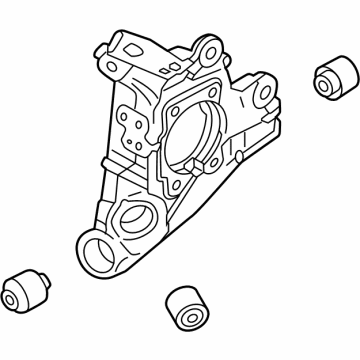

Nissan Murano Housing Assy-Rear Axle,LH

Part Number: 43019-CN200$519.55 MSRP: $768.22You Save: $248.67 (33%)Ships in 1-2 Business Days

Nissan Murano Housing Assy-Rear Axle,RH

Part Number: 43018-CN200$519.55 MSRP: $768.22You Save: $248.67 (33%)Ships in 1-2 Business Days

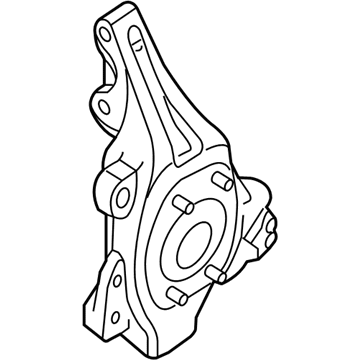

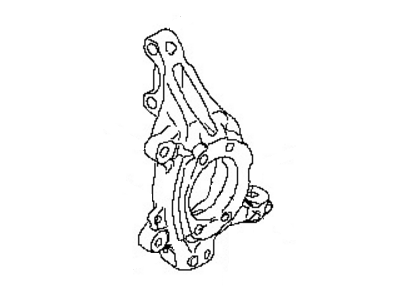

Nissan Murano Spindle - KNUCKLE, LH

Part Number: 40015-CN000$598.75 MSRP: $885.33You Save: $286.58 (33%)Ships in 1-2 Business Days

Nissan Murano Knuckle Spindle-RH

Part Number: 40014-5AA0A$549.76 MSRP: $776.50You Save: $226.74 (30%)Ships in 1-3 Business Days

Nissan Murano Spindle - KNUCKLE, RH

Part Number: 40014-CN000$642.75 MSRP: $885.33You Save: $242.58 (28%)Ships in 1-2 Business DaysNissan Murano Housing-Rear Axle,RH

Part Number: 43018-1AA0A$549.27 MSRP: $775.80You Save: $226.53 (30%)Ships in 1-3 Business DaysNissan Murano Knuckle Spindle-RH

Part Number: 40014-5AA1A$549.76 MSRP: $776.50You Save: $226.74 (30%)Ships in 1-3 Business DaysNissan Murano Housing Rear Axle RH

Part Number: 43021-1AA0A$476.33 MSRP: $672.78You Save: $196.45 (30%)Ships in 1-3 Business DaysNissan Murano Knuckle Spindle-RH

Part Number: 40014-6SA0A$186.48 MSRP: $263.38You Save: $76.90 (30%)Ships in 1-3 Business DaysNissan Murano Housing-Rear Axle,LH

Part Number: 43019-1AA0A$512.78 MSRP: $724.27You Save: $211.49 (30%)Ships in 1-3 Business DaysNissan Murano Knuckle Spindle-LH

Part Number: 40015-5AA1A$549.76 MSRP: $776.50You Save: $226.74 (30%)Ships in 1-3 Business DaysNissan Murano Spindle-KNUCKLE,LH

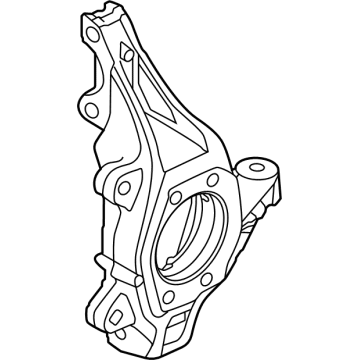

Part Number: 40015-JP00A$521.62 MSRP: $736.75You Save: $215.13 (30%)Ships in 1-3 Business DaysNissan Murano Spindle-KNUCKLE,RH

Part Number: 40014-JP00A$521.62 MSRP: $736.75You Save: $215.13 (30%)Ships in 1-3 Business DaysNissan Murano Housing Assy-Rear Axle,RH

Part Number: 43018-6SA0B$270.95 MSRP: $382.70You Save: $111.75 (30%)Ships in 1-3 Business DaysNissan Murano Knuckle Spindle-LH

Part Number: 40015-5AA0A$549.76 MSRP: $776.50You Save: $226.74 (30%)Ships in 1-3 Business DaysNissan Murano Housing Rear Axle LH

Part Number: 43022-1AA0A$443.72 MSRP: $587.55You Save: $143.83 (25%)Ships in 1-3 Business DaysNissan Murano Knuckle Spindle-LH

Part Number: 40015-6SA0A$186.48 MSRP: $263.38You Save: $76.90 (30%)Ships in 1-3 Business DaysNissan Murano Housing Assy-Rear Axle,LH

Part Number: 43019-6SA0B$290.20 MSRP: $409.88You Save: $119.68 (30%)Ships in 1-3 Business Days

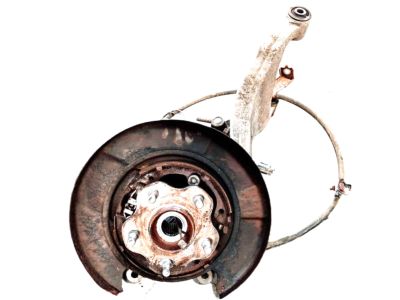

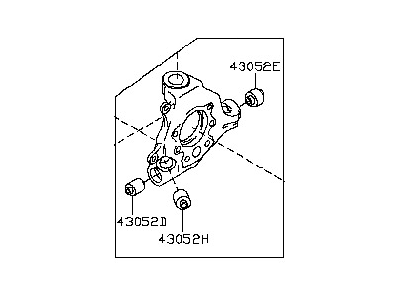

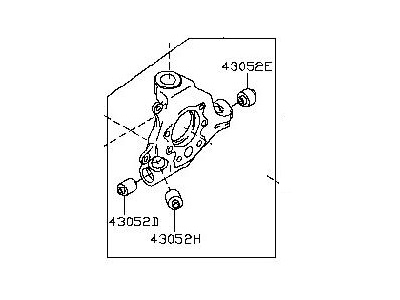

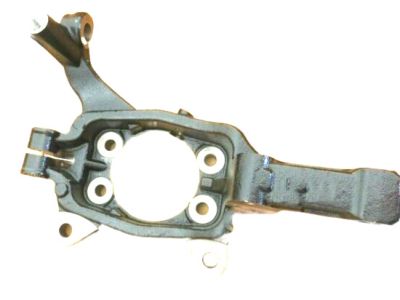

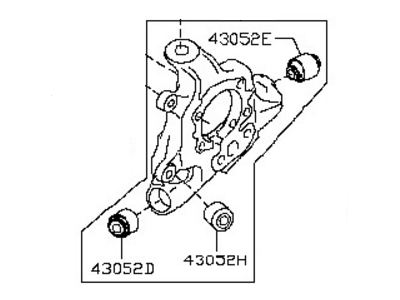

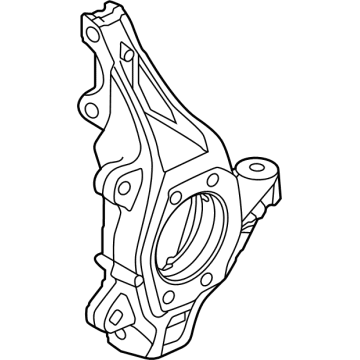

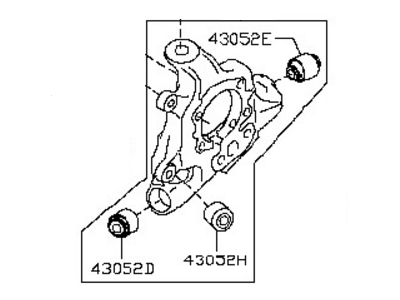

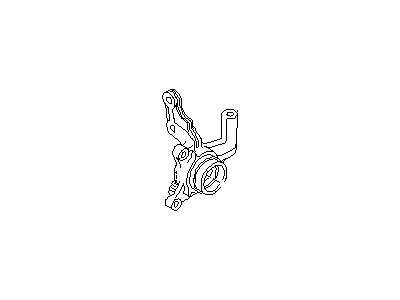

Nissan Murano Steering Knuckle

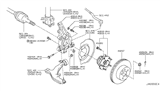

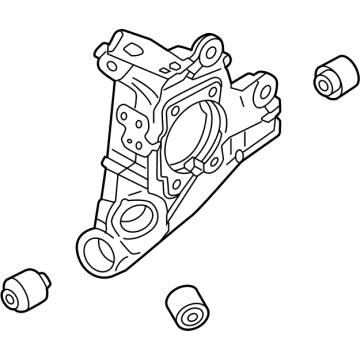

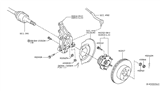

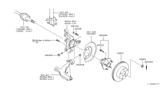

The Nissan Murano Steering Knuckle is one of the prominent parts which can explain the excellence of the brand. Steering Knuckle is an important component which joins the suspension system and the steering system by guiding the movement of the front wheels and providing better control and balance. Applicable to almost every Nissan Murano model, ranging from RWD to FWD, AWD or 4WD, the Steering Knuckle is a part dedicated to the improvement of the car's performance and safety. The cross-section gives firm places to connect to control arms, tie-rod ends, and the wheel hub and it enables the translated up and down and sideways in regards to road conditions. Progress in the Nissan Murano Steering Knuckle, the changes from kingpin to the modern ball joint models are worth noting, and they show a clear improvement of the automobiles' engineering. The Steering Knuckle should be inspected frequently for the proper running of the vehicle and its safety especially when, installing related parts. However, the highly pertinent product is the Nissan Murano Steering Knuckle, which distinguishes the car in the automotive market for its application of new material and design components, all of which ultimately affect the general driving experience. As known to be very efficient, the Nissan Murano Steering Knuckle is vital in contributing to the fact that Murano is one of the highly recommended mid-size SUVs in the market.

If you need any OEM Nissan Murano Steering Knuckle, feel free to choose them out of our huge selection of genuine Nissan Murano Steering Knuckle. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Murano Steering Knuckle Parts Questions & Experts Answers

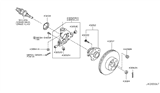

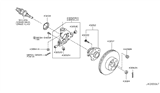

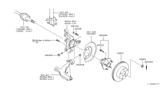

- Q: How do you remove and install a Steering Knuckle on Nissan Murano?A:To take off the wheel the lug nuts have to be unscrewed, the car has to be lifted using a jack and supported on the stands before the wheel can be removed. Subsequently, unscrew the cotter pin and the driveaxle/hub nut and pull out the brake disc. Locate the wheel speed sensor and unclip it from the knuckle then finally, get ahold of the tie-rod end and remove it from the steering knuckle. Loosen and yet do not take out the strut to steering knuckle nuts and after that, disengage the control arm ball joint from the steering knuckle. Lift the steering knuckle away from the driveaxle by unscrewing the knuckle bolts and fasten the other end of the CV joint with wire. To remove the knuckle, undo the strut-to-knuckle bolts and pull the knuckle away from the strut After this undo the hub-to-steering knuckle bolts and pull the two to separate them and remove the brake disc splash shield. For installation, tighten the six M8 bolts to seventy and sixty-five newton meters for the hub, knuckle and the splash shield respectively. Apply the multi-purpose grease on the splines of the driveaxle, align the knuckle and the hub, and finally screw the driveaxle on the hub. Insert the knuckle into the strut flange and fit in the bolts and nuts though they should not be tightened at this time. Next, the control arm ball joint was bolted to the steering knuckle followed by joining the tie-rod end to the steering knuckle arm, the torque applied was 60 lb/ft for the Tie Rod End nut, while the strut to knuckle nuts were torqued at 80 lbft and a new cotter pin was inserted through a hole in the tie rod ball stud. Put the brake disc on the hub and locate the caliper onto it; screw the driveaxle/hub nut and tweak to meet the recommended torque. Last, the wheel and lug nuts have to be fitted and put in place and then the vehicle can be lowered and the lug nuts tightened to the recommended torque.

Related Nissan Murano Parts

Browse by Year

2025 Steering Knuckle 2024 Steering Knuckle 2023 Steering Knuckle 2022 Steering Knuckle 2021 Steering Knuckle 2020 Steering Knuckle 2019 Steering Knuckle 2018 Steering Knuckle 2017 Steering Knuckle 2016 Steering Knuckle 2015 Steering Knuckle 2014 Steering Knuckle 2013 Steering Knuckle 2012 Steering Knuckle 2011 Steering Knuckle 2010 Steering Knuckle 2009 Steering Knuckle 2008 Steering Knuckle 2007 Steering Knuckle 2006 Steering Knuckle 2005 Steering Knuckle 2004 Steering Knuckle 2003 Steering Knuckle