×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

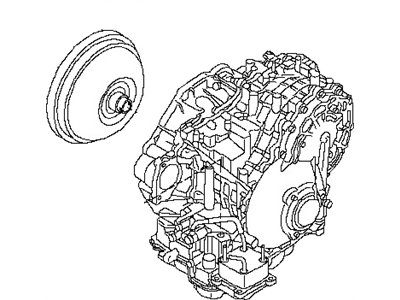

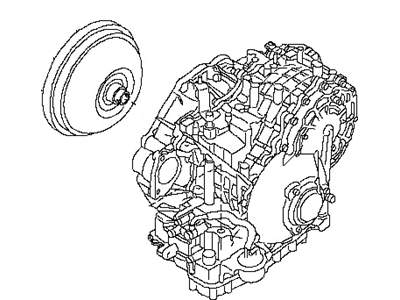

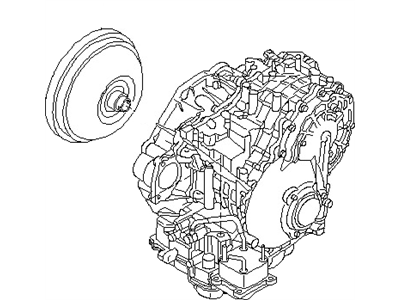

Genuine Nissan Murano Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Transmission Assemblies found

Nissan Murano Automatic Transmission Assembly

Part Number: 31020-1XE1C$3200.11 MSRP: $3874.23You Save: $674.12 (18%)Ships in 1-3 Business Days

Nissan Murano Automatic Transmission Assembly

Part Number: 31020-1XE1B$3200.11 MSRP: $3874.23Limited AvailabilityYou Save: $674.12 (18%)Nissan Murano Automatic Transmission Assembly

Part Number: 31020-3WX2A$3520.68 MSRP: $4241.99You Save: $721.31 (17%)Ships in 1-3 Business DaysNissan Murano Transaxle Assembly Automatic

Part Number: 31020-3WX6E$3520.68 MSRP: $4241.99You Save: $721.31 (17%)Ships in 1-3 Business DaysNissan Murano Automatic Transaxle

Part Number: 31020-3YX0C$6855.35 MSRP: $8299.46You Save: $1444.11 (18%)Ships in 1-3 Business DaysNissan Murano Automatic Transaxle

Part Number: 31020-3YX0D$6320.62 MSRP: $7631.74You Save: $1311.12 (18%)Ships in 1-3 Business DaysNissan Murano Automatic Transmission Assembly

Part Number: 310C0-1XD0D$2183.00 MSRP: $2642.86You Save: $459.86 (18%)Ships in 1-3 Business DaysNissan Murano Automatic Transmission Assembly

Part Number: 31020-3WX1E$3503.88 MSRP: $4241.99You Save: $738.11 (18%)Ships in 1-3 Business DaysNissan Murano Automatic Transmission Assembly

Part Number: 310C0-1XE0B$3200.11 MSRP: $3874.23Limited AvailabilityYou Save: $674.12 (18%)Nissan Murano Automatic Transmission Assembly

Part Number: 310C0-1XE0A$3200.11 MSRP: $3874.23You Save: $674.12 (18%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

Nissan Murano Transmission Assembly

If you need any OEM Nissan Murano Transmission Assembly, feel free to choose them out of our huge selection of genuine Nissan Murano Transmission Assembly. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Murano Transmission Assembly Parts Questions & Experts Answers

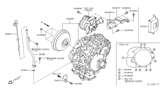

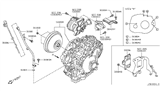

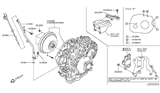

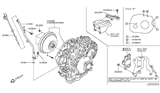

- Q: How do you remove and install the engine and trans axle assembly from a Nissan Murano?A:To dismantle the engine and trans axle from the vehicle; paint match marks between the torque converter and drive plate since they will be released and reassembled, then unlock the torque converter bolts by turning the crank shaft to expose each bolt. Separate the splice wiring connections of the trans axle and then remove the wiring harness connected to the trans axle, dipstick tube and then the trans axle mounts attached to the sub frame. Loosen and disconnect the engine-to-trans axle bolts for proper orientation of reassembly and then extract the trans axle from the engine; slide it back, including the removal of trans axle cooler hose and the torque converter, and sealing the front to avert contamination. Regarding installation, it's advisable to flush the trans axle cooler and hoses with solvent, and in some cases, you might perform the second flush with clean automatic transmission fluid. To do this, make sure that the torque converter hub is locked into the pump securely while the front grid of the torque converter should be at least half an inch behind the trans axle housing. Swing the trans axle to the back of the engine using the marks made previously and put lugs on the torque converter to the drive plate, then move the trans axle forward to have dowel pins and torque converter interfaced. Fit trans axle mounting bolts in the correct position and without applying excessive force on the components and then tighten trans axle to engine bolts to the recommended torque. Bolt on the torque converter and tighten the bolts, and then top-up the trans axle with fluid because the torque convertor could be empty and it might take more fluid than when changing the fluid normally. Ignite the engine, engage the parking brake and run through all the gears of the trans axle thrice to test Shift Cable mobility. With the trans axle in Park or Neutral, allow the engine to warm up to its normal temperature and then shut the engine off and check the fluid level other than making a road test to check for leaks.

Related Nissan Murano Parts

Browse by Year

2024 Transmission Assembly 2023 Transmission Assembly 2022 Transmission Assembly 2021 Transmission Assembly 2020 Transmission Assembly 2019 Transmission Assembly 2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly