×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan Rogue Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Drive Belts found

Nissan Rogue Fan & Alternator Belt

Part Number: 11720-3TA0A$64.65 MSRP: $93.63You Save: $28.98 (31%)Ships in 1-3 Business Days

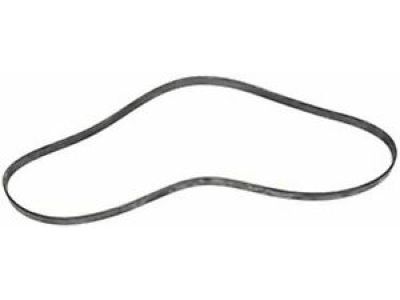

Nissan Rogue Serpentine Belt

Part Number: 11720-4BA0A$66.89 MSRP: $96.88You Save: $29.99 (31%)Ships in 1-2 Business Days

Nissan Rogue Fan & Alternator Belt

Part Number: 11720-JG30B$58.75 MSRP: $85.08You Save: $26.33 (31%)Ships in 1-3 Business Days

Nissan Rogue Serpentine Belt

Part Number: 11720-JG30A$58.75 MSRP: $85.08You Save: $26.33 (31%)Ships in 1-2 Business Days

Nissan Rogue Belt Assembly

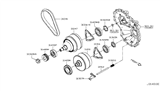

Part Number: 31240-1XF0B$295.26 MSRP: $417.03You Save: $121.77 (30%)Ships in 1-3 Business Days

Nissan Rogue Chain Oil Pump

Part Number: 33152-29X0B$12.27 MSRP: $16.92You Save: $4.65 (28%)Ships in 1-3 Business DaysNissan Rogue Belt-Fan & ALTERNATOR

Part Number: 11720-6RC0A$68.00 MSRP: $98.48You Save: $30.48 (31%)Ships in 1-3 Business DaysNissan Rogue BELT-FAN & ALTERNATOR

Part Number: 11720-6RC0E$63.83 MSRP: $92.45You Save: $28.62 (31%)Ships in 1-3 Business DaysNissan Rogue BELT-FAN & ALTERNATOR

Part Number: 11720-6RC0D$63.54 MSRP: $92.02You Save: $28.48 (31%)Ships in 1-2 Business Days

Nissan Rogue Drive Belt

If you need any OEM Nissan Rogue Drive Belt, feel free to choose them out of our huge selection of genuine Nissan Rogue Drive Belt. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

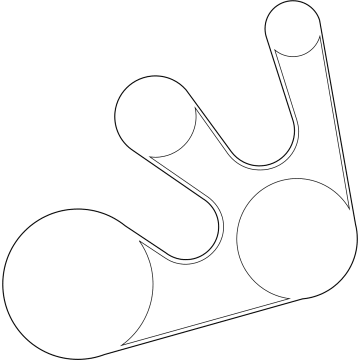

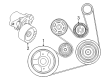

Nissan Rogue Drive Belt Parts Questions & Experts Answers

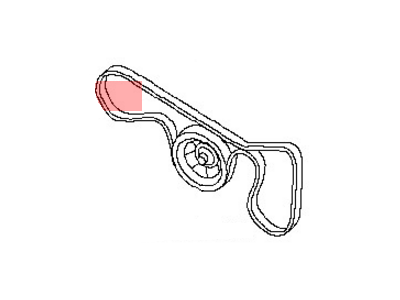

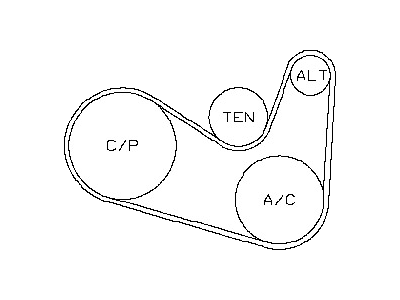

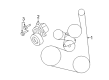

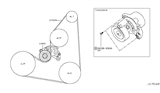

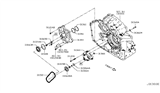

- Q: How do you maintain and replace a serpentine drivebelt in an engine on Nissan Rogue?A:These models employ the serpentine drivebelt whose tension is normally maintained by an automatic tensioner adjuster; therefore, the correct tension of the belt is important in the running of the engine. Since these components are made of materials that are expected to stretch due to the levels of stress they are put through and since these are components that, by their nature, wear out and turn out to be less than efficient after some time, drivebelts therefore have to be checked from time to time. The serpentine drivebelt takes power to all the accessories in the car in place and is therefore crucial. To check the drivebelt, the engine should be off, the bonnet should be opened and should find the drivebelt. Visually inspect every belt with a flashlight where one side may appear smooth while the other side shows the sign of separation, cracking, fraying, or glazing the belt, and press the twofold sides of the belt at the same time while turning them in opposite directions. In case some problems are identified, it is advised to change the belt on the equipment. Also, visually inspect the drivebelt indicator stretch; if the word "LIMIT" appears on the inside of the indicator, then it should be replaced. For drivebelt replacement, the negative battery operation must be turned off, the right front wheel lug nuts loosened, the vehicle heightened securely, and the wheel and inner splash have to be removed. Turn the belt tensioner clockwise to reduce tension and secure it with a screwdriver or metal rod, while previously tightening this bolt: the tensioner pulley. Erase the drivebelt from the tensioner and Accsents, fit the new drivebelt taking care to the instructions routed and reconnect the battery. For vehicles provided with automatic tensioner, first of all, you unpack the drive belt and then the tensioner fasteners and finally the tensioner but after all, you tighten the tensioner mounting fasteners to the recommended torque only.