×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

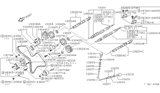

Genuine Nissan Rogue Valve Stem Oil Seal

Engine Valve Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Valve Stem Oil Seals found

Nissan Rogue Seal-Oil,Valve

Part Number: 13207-84A00$6.92 MSRP: $9.53You Save: $2.61 (28%)Ships in 1-2 Business Days

Nissan Rogue Seal-Lip Valve

Part Number: 13207-3Z00A$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Rogue Seal-Oil,Valve

Part Number: 13207-3Z000$5.26 MSRP: $7.25You Save: $1.99 (28%)Ships in 1-3 Business Days

Nissan Rogue Seal-Oil,Valve

Part Number: 13207-D4201$6.75 MSRP: $9.53You Save: $2.78 (30%)Ships in 1-2 Business Days

Nissan Rogue Seal-Lip Valve

Part Number: 13207-00Q0A$2.87 MSRP: $3.95You Save: $1.08 (28%)Ships in 1-2 Business Days

Nissan Rogue Seal-Oil,Valve

Part Number: 13207-ET000$4.67 MSRP: $6.43You Save: $1.76 (28%)Ships in 1-3 Business DaysNissan Rogue Seal-Lip Valve

Part Number: 13207-ET00A$5.83 MSRP: $8.03You Save: $2.20 (28%)Ships in 1-3 Business DaysNissan Rogue Seal-Oil,Valve

Part Number: 13207-5NA0C$5.32 MSRP: $7.33You Save: $2.01 (28%)Ships in 1-3 Business Days

Nissan Rogue Valve Stem Oil Seal

If you need any OEM Nissan Rogue Valve Stem Oil Seal, feel free to choose them out of our huge selection of genuine Nissan Rogue Valve Stem Oil Seal. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Rogue Valve Stem Oil Seal Parts Questions & Experts Answers

- Q: How do you remove and replace the valve stem oil seal in a cylinder head on Nissan Rogue?A:Loosen the Cylinder Head and put it on a hard surface or better still a working table. Apply a large clamp type of valve spring compressor that has an adapter where by when compressing each valve spring, the bottom section of the tool should be placed under the valve being compressed. Wind the spring just to the extent that you will be able to remove the keepers with a magnet or small pliers. Withdraw the valve spring together with the retainer and then carefully take out the rusted valve stem oil seal with the help of the pliers. Examine the exterior and the stem of the valve for excessive wear, and turn the valve relative to its guide to determine if it moves off center, if so then the valve is bent. Wipe the valve up and down in the guide and if it sticks the groove must have become rotated or the guide worn and the cylinder head will have to be machined. Apply a drop of oil on the valve stem before positioning the valve in the cylinder head; you need to place a plastic protector around the new rubber seal as it is fitted to avoid damaging it. If a seal protector is not available, crowd cellulose tape around the valve stem. Apply multi- purpose grease on the new seal and fit it over the valve stem and remove the protector or tape on it. Lightly engaging a deep socket of the right size, give the new seal a tap and place it down on the top of the valve guide. Align the spring over the valve along with the retainer engaged, then using the fingers and a small hammer, squeeze the valve spring and retainer and then engage the keepers on the groove with a small amount of grease if needed. Remove the pressure in the spring tool and make sure that the keepers are properly locked in place. After that, re-attach the lifters and camshafts back then finish the process by following the removal process in the opposite manner. Ignition of the engine and ensure that there is no signs of oil stains and strange noises coming from the valve cover.

Related Nissan Rogue Parts

Browse by Year

2024 Valve Stem Oil Seal 2023 Valve Stem Oil Seal 2022 Valve Stem Oil Seal 2021 Valve Stem Oil Seal 2020 Valve Stem Oil Seal 2019 Valve Stem Oil Seal 2018 Valve Stem Oil Seal 2017 Valve Stem Oil Seal 2016 Valve Stem Oil Seal 2015 Valve Stem Oil Seal 2014 Valve Stem Oil Seal 2013 Valve Stem Oil Seal 2012 Valve Stem Oil Seal 2011 Valve Stem Oil Seal 2010 Valve Stem Oil Seal 2009 Valve Stem Oil Seal 2008 Valve Stem Oil Seal