×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

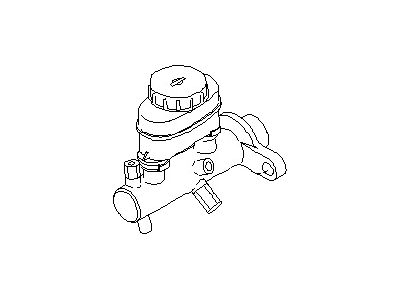

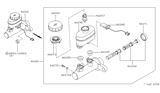

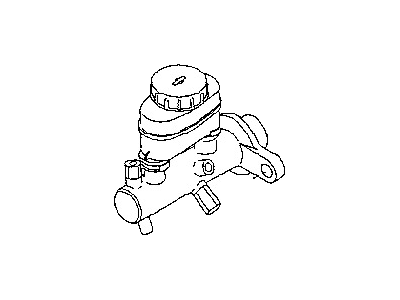

Genuine Nissan Sentra Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

44 Brake Master Cylinders found

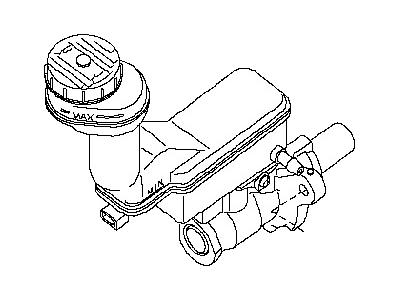

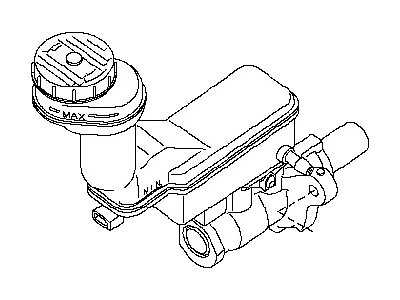

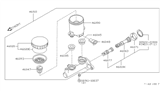

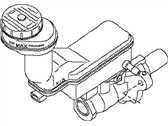

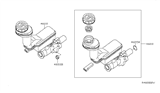

Nissan Sentra Cylinder Brake Master

Part Number: 46010-3SG1B$327.51 MSRP: $499.87You Save: $172.36 (35%)Ships in 1-3 Business DaysNissan Sentra Cylinder Brake Master

Part Number: 46010-ZJ91A$248.39 MSRP: $367.78You Save: $119.39 (33%)Ships in 1-3 Business DaysNissan Sentra Brake Master Cylinder Assembly

Part Number: 46010-ET010$227.20 MSRP: $336.42You Save: $109.22 (33%)Ships in 1-3 Business DaysNissan Sentra Brake Master Cylinder Assembly

Part Number: 46010-3SG0B$227.10 MSRP: $336.27You Save: $109.17 (33%)Ships in 1-3 Business DaysNissan Sentra Cylinder Brake Master

Part Number: 46010-ZJ90A$225.98 MSRP: $311.27You Save: $85.29 (28%)Ships in 1-2 Business DaysNissan Sentra Brake Master Cylinder Assembly

Part Number: 46010-3SG1A$327.51 MSRP: $499.87You Save: $172.36 (35%)Ships in 1-3 Business DaysNissan Sentra Brake Master Cylinder Assembly

Part Number: 46010-3SG0A$227.10 MSRP: $336.27You Save: $109.17 (33%)Ships in 1-3 Business DaysNissan Sentra Brake Master Cylinder Assembly

Part Number: 46010-6LA2D$121.11 MSRP: $175.40You Save: $54.29 (31%)

| Page 1 of 3 |Next >

1-20 of 44 Results

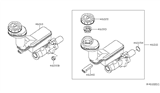

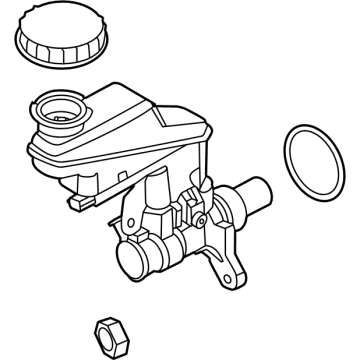

Nissan Sentra Brake Master Cylinder

If you need any OEM Nissan Sentra Brake Master Cylinder, feel free to choose them out of our huge selection of genuine Nissan Sentra Brake Master Cylinder. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Sentra Brake Master Cylinder Parts Questions & Experts Answers

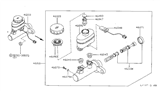

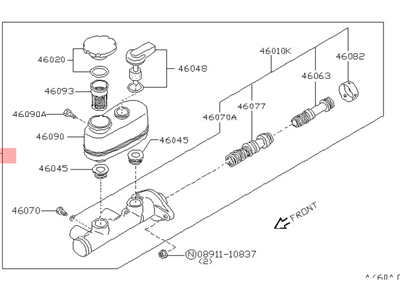

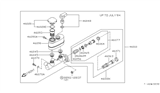

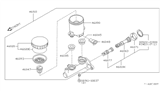

- Q: How do you remove the master cylinder on Nissan Sentra?A:Disconnecting the battery and removing the air filter housing is always the first step to take before removing the Brake Master Cylinder. It is also necessary to disconnect the electrical connector for the fluid level warning switch and, where applicable, disengage and close off the clutch fluid hose for a vehicle with manual transaxle. Then again, carefully draw off as much fluid as you can from the reservoir using a syringe without spilling any. Commence by loosening fittings upon those ends of Brake Lines that enter into that cylinder. Detach it from its nuts which connects it to power booster having care on not leaving behind any remaining substance within this bottle. To install it, bench bleed new Brake Master Cylinder through holding it in a vise clamping bleeder tubes at output ports. Fill brake reservoir with recommended brake fluid then slowly press pistons into Brake Master Cylinder causing expulsion of air in chambers under pressure back into reservoir. One after another remove each of these bleed pipes and put plugs inside these openings so that there will be no spillage of any liquid or air getting inside. Apply silicone grease to the power booster bore and coat end O-ring of a Brake Master Cylinder inserting a new O-ring seal afterwards. The next step would be to place your hand on top of that booster pushing its studs through holes on other side until you feel them tightening up your fingers around nuts but not more than what is required at this point; now thread connections onto both its cylinders tight enough too! Fill reservoir with fluid, bleed lines at Brake Master Cylinder then proceed bleeding rest system should bring things back order soonest possible time possible-before reattaching battery or even attempting anything else lest some damage done internally somewhere resulting in loss braking performance leading complete failure altogether if not attended timely enough.

Related Nissan Sentra Parts

Browse by Year

2025 Brake Master Cylinder 2024 Brake Master Cylinder 2023 Brake Master Cylinder 2022 Brake Master Cylinder 2021 Brake Master Cylinder 2020 Brake Master Cylinder 2019 Brake Master Cylinder 2018 Brake Master Cylinder 2017 Brake Master Cylinder 2016 Brake Master Cylinder 2015 Brake Master Cylinder 2014 Brake Master Cylinder 2013 Brake Master Cylinder 2012 Brake Master Cylinder 2011 Brake Master Cylinder 2010 Brake Master Cylinder 2009 Brake Master Cylinder 2008 Brake Master Cylinder 2007 Brake Master Cylinder 2006 Brake Master Cylinder 2005 Brake Master Cylinder 2004 Brake Master Cylinder 2003 Brake Master Cylinder 2002 Brake Master Cylinder 2001 Brake Master Cylinder 2000 Brake Master Cylinder 1999 Brake Master Cylinder 1998 Brake Master Cylinder 1997 Brake Master Cylinder 1996 Brake Master Cylinder 1995 Brake Master Cylinder 1994 Brake Master Cylinder 1993 Brake Master Cylinder 1992 Brake Master Cylinder 1991 Brake Master Cylinder 1990 Brake Master Cylinder 1989 Brake Master Cylinder 1988 Brake Master Cylinder 1987 Brake Master Cylinder 1986 Brake Master Cylinder 1985 Brake Master Cylinder 1984 Brake Master Cylinder 1983 Brake Master Cylinder 1982 Brake Master Cylinder