×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

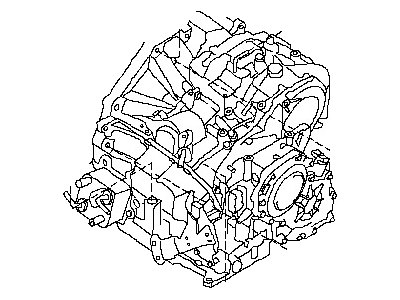

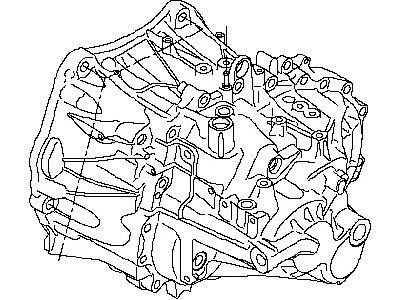

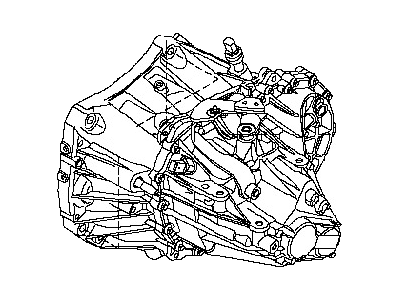

Genuine Nissan Sentra Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

91 Transmission Assemblies found

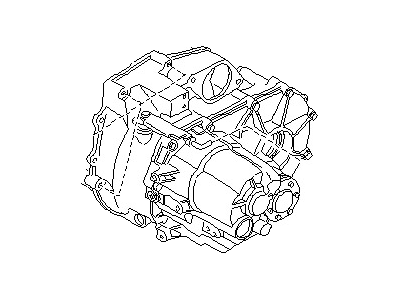

Nissan Sentra Automatic Transaxle

Part Number: 31020-X428D$3126.38 MSRP: $3764.63You Save: $638.25 (17%)Ships in 1-3 Business DaysNissan Sentra Automatic Transmission Assembly

Part Number: 31020-X428E$3126.38 MSRP: $3764.63You Save: $638.25 (17%)Ships in 1-3 Business DaysNissan Sentra Manual Transaxle

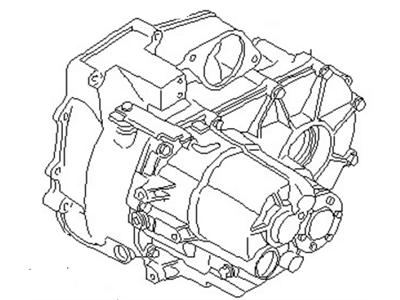

Part Number: 32010-00Q3P$2919.72 MSRP: $3534.77You Save: $615.05 (18%)Ships in 1-3 Business DaysNissan Sentra Automatic Transaxle

Part Number: 31020-70X8C$3126.38 MSRP: $3764.63You Save: $638.25 (17%)Ships in 1-3 Business DaysNissan Sentra Manual Transaxle

Part Number: 32010-02Q3F$2931.46 MSRP: $3548.99You Save: $617.53 (18%)Ships in 1-3 Business DaysNissan Sentra Automatic Transaxle

Part Number: 31020-70X4A$3126.38 MSRP: $3764.63You Save: $638.25 (17%)Ships in 1-3 Business DaysNissan Sentra Automatic Transaxle

Part Number: 31020-3VX7E$3050.53 MSRP: $3672.80You Save: $622.27 (17%)Ships in 1-3 Business DaysNissan Sentra Manual Transaxle

Part Number: 32010-ET80A$2919.72 MSRP: $3534.77You Save: $615.05 (18%)Ships in 1-3 Business DaysNissan Sentra Manual Transmission Assembly

Part Number: 32010-64Y16$1873.62 MSRP: $2268.30Limited AvailabilityYou Save: $394.68 (18%)Nissan Sentra Manual Transaxle

Part Number: 320B0-0M603$1782.87 MSRP: $2158.44Limited AvailabilityYou Save: $375.57 (18%)Nissan Sentra Manual Transaxle

Part Number: 32010-73A68$2245.56 MSRP: $2718.60Limited AvailabilityYou Save: $473.04 (18%)Nissan Sentra Manual Transaxle

Part Number: 32010-01A02$1494.77 MSRP: $1948.85Limited AvailabilityYou Save: $454.08 (24%)Nissan Sentra Manual Transaxle

Part Number: 32010-01A01$1494.77 MSRP: $1948.85Limited AvailabilityYou Save: $454.08 (24%)Nissan Sentra Manual Transaxle

Part Number: 32010-02A01$1521.36 MSRP: $1983.52Limited AvailabilityYou Save: $462.16 (24%)Nissan Sentra Manual Transaxle

Part Number: 32010-11A01$1631.40 MSRP: $2126.98Limited AvailabilityYou Save: $495.58 (24%)Nissan Sentra Manual Transaxle

Part Number: 32010-73A88$2245.56 MSRP: $2718.60Limited AvailabilityYou Save: $473.04 (18%)Nissan Sentra Manual Transaxle

Part Number: 32010-73A08$2245.56 MSRP: $2718.60Limited AvailabilityYou Save: $473.04 (18%)Nissan Sentra Manual Transaxle

Part Number: 32010-11M63$2291.67 MSRP: $2774.41Limited AvailabilityYou Save: $482.74 (18%)

Nissan Sentra Automatic Transmission Assembly

Part Number: 31020-X427E$2920.73 MSRP: $3515.66You Save: $594.93 (17%)Nissan Sentra Automatic Transmission Assembly

Part Number: 31020-X427A$2920.73 MSRP: $3515.66You Save: $594.93 (17%)

| Page 1 of 5 |Next >

1-20 of 91 Results

Nissan Sentra Transmission Assembly

If you need any OEM Nissan Sentra Transmission Assembly, feel free to choose them out of our huge selection of genuine Nissan Sentra Transmission Assembly. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan Sentra Transmission Assembly Parts Questions & Experts Answers

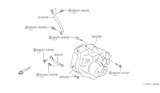

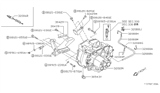

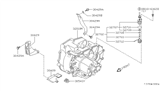

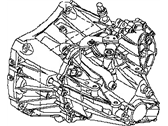

- Q: How do you remove and install a manual transaxle on Nissan Sentra?A:To remove the transaxle, first raise the vehicle and support it securely on a hoist or jackstands, then drain the lubricant from the transaxle. Disconnect the clutch release cylinder hydraulic line from the transaxle, being prepared for fluid spillage. Remove the engine and transaxle as an assembly, disconnect the wiring from the transaxle connections, and remove the wiring harness. Next, remove the starter from the transaxle. Support the transaxle with a floor jack, then remove the transaxle-to-engine mounting bolts, organizing them by length for reinstallation. Finally, separate the transaxle from the engine. For installation, if the clutch components were removed, install them and always replace the clutch release cylinder inside the bellhousing. Slide the transaxle forward, ensuring the dowel pins engage properly and the input shaft aligns with the clutch plate hub splines without using excessive force. Install the transaxle housing-to-engine bolts and tighten them to the specified torque, ensuring they are in the correct holes. Complete the installation by reversing the removal steps, filling the transaxle with fluid, and bleeding the clutch.

Related Nissan Sentra Parts

Browse by Year

2023 Transmission Assembly 2022 Transmission Assembly 2021 Transmission Assembly 2020 Transmission Assembly 2019 Transmission Assembly 2018 Transmission Assembly 2017 Transmission Assembly 2016 Transmission Assembly 2015 Transmission Assembly 2014 Transmission Assembly 2013 Transmission Assembly 2012 Transmission Assembly 2011 Transmission Assembly 2010 Transmission Assembly 2009 Transmission Assembly 2008 Transmission Assembly 2007 Transmission Assembly 2006 Transmission Assembly 2005 Transmission Assembly 2004 Transmission Assembly 2003 Transmission Assembly 2002 Transmission Assembly 2001 Transmission Assembly 2000 Transmission Assembly 1999 Transmission Assembly 1998 Transmission Assembly 1997 Transmission Assembly 1996 Transmission Assembly 1995 Transmission Assembly 1994 Transmission Assembly 1993 Transmission Assembly 1992 Transmission Assembly 1991 Transmission Assembly 1990 Transmission Assembly 1989 Transmission Assembly 1988 Transmission Assembly 1987 Transmission Assembly 1986 Transmission Assembly 1985 Transmission Assembly 1984 Transmission Assembly 1983 Transmission Assembly 1982 Transmission Assembly