×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 300ZX Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Cylinder Heads found

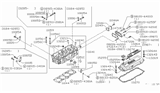

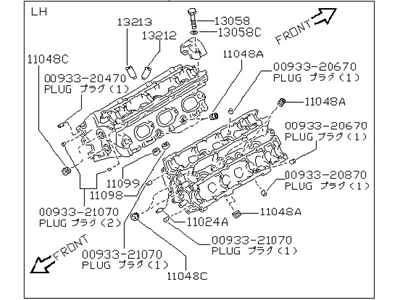

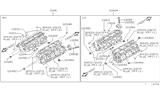

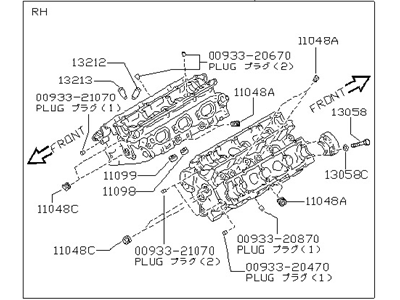

Nissan 300ZX Cylinder Head Assembly

Part Number: 11091-V5280$698.67 MSRP: $910.91Limited AvailabilityYou Save: $212.24 (24%)Nissan 300ZX Head Assembly-Cylinder L

Part Number: 11091-21V80$698.67 MSRP: $910.91Limited AvailabilityYou Save: $212.24 (24%)Nissan 300ZX Cylinder Head Assembly

Part Number: 11090-21V10$698.67 MSRP: $910.91Limited AvailabilityYou Save: $212.24 (24%)Nissan 300ZX Cylinder Head Assembly

Part Number: 11041-21V10$726.53 MSRP: $947.23Limited AvailabilityYou Save: $220.70 (24%)

Nissan 300ZX Cylinder Head

If you need any OEM Nissan 300ZX Cylinder Head, feel free to choose them out of our huge selection of genuine Nissan 300ZX Cylinder Head. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

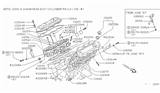

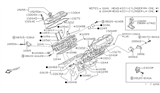

Nissan 300ZX Cylinder Head Parts Questions & Experts Answers

- Q: What steps should be taken for thorough cleaning and inspection of the cylinder head and valve train components during an engine overhaul on Nissan 300ZX?A:If you scrub the cylinder head and all the other associated valve train parts and then do an inspection, you will be in a position to determine how much valve servicing has to be conducted during the overall engine rebuilding. First, remove all the residues of the gasket and the sealing compound from the head, intake manifold and the exhaust manifold seating surfaces with gasket scraper. Scrape or rub off any accumulated scale around the coolant passages and scrub the oil holes with a stiff wire brush to clean them succlly. In each threaded hole, apply the proper size tap to remove any oxidation and the thread lock, clearing the particles with compressed air if possible. Treat the outside threads of the exhaust and intake manifold studs in the same way with a die Clean the cylinder head with solvent and then blow this dry with compressed air CAUTION Do not over tighten the cylinder head bolts They should be tightened to a torque of 30 Ft.Lbs. Decarbonizing chemicals may help in cleaning but caution should be observed especial on aluminum heads. Remove and clean the rocker arms, valve springs, retainers, collets and spring seats with solvent, see to it that every valve assemblies are cleaned separately so that there will be no exchange of parts. If the head was removed, look at the head for signs of cracking and coolant leakage, in addition, the head gasket mating surface should be checked for warpage with a straight edge and feeler gauges. Check the valve seats for pitting and / or damage and check the possible lateral motion of the valve stem by using dial gauge. Examine the camshaft bearing surfaces for such signs of wear and check the oil clearance with the tools. Investigate the processes of wear on the valve rocker arms and shafts and also check for scuffing on the lifter pads. Remove any badly scored or excessively worn pieces, and make sure that all the oil ways are clear. Check the face of all valves for any cracks visible and check the overall margin of the valve with the required standard and replace any valve that has a narrow margin. Look through each valve spring and determine whether it has worn out or not, and whether the spring retainers and keepers are distorted or not. If the valve components are worn out then it may require servicing before it can be fitted back into cylinder head; though, if it is established that there is or are worn out noticeable parts, then the valve train may be fitted without much servicing.