×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

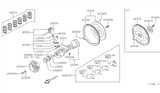

Genuine Nissan 300ZX Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

66 Pistons found

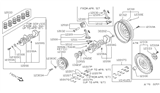

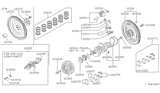

Nissan 300ZX Piston, W/PIN

Part Number: A2010-30P72$113.73 MSRP: $156.65You Save: $42.92 (28%)Ships in 1-2 Business DaysNissan 300ZX Piston With Pin

Part Number: 12010-V7103$58.87 MSRP: $99.87You Save: $41.00 (42%)Ships in 1-2 Business DaysNissan 300ZX Piston With Pin

Part Number: A2010-30P62$86.43 MSRP: $119.05You Save: $32.62 (28%)Ships in 1-2 Business DaysNissan 300ZX Piston W/Pin

Part Number: 12010-02P03$64.58 MSRP: $91.22Limited AvailabilityYou Save: $26.64 (30%)Nissan 300ZX Piston,W/Pin

Part Number: 12010-30P61$66.12 MSRP: $93.38Limited AvailabilityYou Save: $27.26 (30%)Nissan 300ZX Piston W/Pin

Part Number: 12010-V5901$64.58 MSRP: $91.22Limited AvailabilityYou Save: $26.64 (30%)Nissan 300ZX Piston,W/Pin

Part Number: 12010-30P02$67.43 MSRP: $95.23Limited AvailabilityYou Save: $27.80 (30%)Nissan 300ZX Piston,W/Pin

Part Number: 12010-30P71$88.98 MSRP: $125.68Limited AvailabilityYou Save: $36.70 (30%)

| Page 1 of 4 |Next >

1-20 of 66 Results

Nissan 300ZX Piston

If you need any OEM Nissan 300ZX Piston, feel free to choose them out of our huge selection of genuine Nissan 300ZX Piston. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 300ZX Piston Parts Questions & Experts Answers

- Q: How should you remove pistons and connecting rod assemblies on Nissan 300ZX?A:Using a ridge reamer, it is essential to carry out the process of removing the remaining of the ridge, which is at the top part of cylinders until it is fully done as a way of preparing for the removal of the pistons. For the ridge reaming tool, the manufacturer's guidelines should be strictly followed, especially when failure to remove the ridge would lead to breaking of the piston rings when attempting to pull out the piston and connected rod. After stripping off all the cylinder wear ridges, turn the engine in such a way that the crank shaft is on the top. shift the connecting rods and the caps; if there are no marks then use a small punch to make marks on the rods and caps out of identification. Tighten all the nuts of the connecting rods half turn and then remove all the nuts and lift off the rod caps and bearing inserts to retain the bearing inserts with the corresponding caps for further examination. To prevent rod and Crankshaft journal or cylinder damage, fit a short piece of plastic or rubber hose over each connecting rod cap bolt during the removal of the pistons and rods. Remove the connecting rod and piston assembly through the peak of the crankcase using a wooden maul to force the piston down through the cylinder block and then be ready to catch the connecting rod as it drops. If resistance is felt, make sure all ridge has been taken off the cylinder. The same process is to follow with the rest of the cylinders, after which the connecting rod caps and bearing inserts are to be replaced on their respective rods, with the nuts only to be tightened by the amount to be gripped by fingers while the old bearing inserts are retained on the rods to avoid injuries on the bearing surfaces.