×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 300ZX Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshafts found

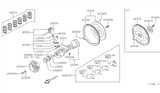

Nissan 300ZX Crankshaft Assembly

Part Number: 12201-02P80$893.43 MSRP: $1164.83Limited AvailabilityYou Save: $271.40 (24%)

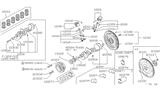

Nissan 300ZX Crankshaft Assembly

Part Number: 12200-30P80$859.35 MSRP: $1120.40You Save: $261.05 (24%)

Nissan 300ZX Crankshaft

If you need any OEM Nissan 300ZX Crankshaft, feel free to choose them out of our huge selection of genuine Nissan 300ZX Crankshaft. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 300ZX Crankshaft Parts Questions & Experts Answers

- Q: How should the crankshaft be cleaned and inspected for damage on Nissan 300ZX?A:Clean the crankshaft with solvent and dry it thoroughly, ensuring to clean the oil holes with a stiff brush and flush them with solvent. Check the main and connecting rod bearing journals for uneven wear, scoring, pitting, or cracks, and inspect the remainder of the crankshaft for any cracks and damage. Measure the diameter of the main and connecting rod journals using a micrometer, taking measurements at several places to detect taper and out-of-round conditions, and compare these measurements to the specified outside diameters. By measuring at multiple points around each journal's circumference, determine if the journal is out of round, and take measurements at each end of the journal, near the crank counterweights, to check for taper. If the crankshaft journals are found to be damaged, tapered, out of round, or worn beyond specified limits, it will need to be reground by an automotive machine shop, and ensure to use the correct oversize bearing inserts if the crankshaft is reconditioned.