×

- Hello

- Login or Register

- Quick Links

- Live Chat

- Track Order

- Parts Availability

- RMA

- Help Center

- Contact Us

- Shop for

- Nissan Parts

- Nissan Accessories

My Garage

My Account

Cart

Genuine Nissan 300ZX Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Piston Ring Sets found

Nissan 300ZX Piston Ring Set

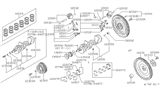

Part Number: 12033-F6511$273.65 MSRP: $386.52You Save: $112.87 (30%)Ships in 1-3 Business DaysNissan 300ZX Ring Set Std

Part Number: 12033-21V00$128.37 MSRP: $181.32Limited AvailabilityYou Save: $52.95 (30%)Nissan 300ZX Ring Set Std

Part Number: 12033-21P00$128.37 MSRP: $181.32Limited AvailabilityYou Save: $52.95 (30%)

Nissan 300ZX Piston Ring Set

If you need any OEM Nissan 300ZX Piston Ring Set, feel free to choose them out of our huge selection of genuine Nissan 300ZX Piston Ring Set. All our parts are offered at unbeatable prices and are supported by the manufacturer's warranty. In addition, we offer quick shipping to have your parts delivered to your door step in a matter of days.

Nissan 300ZX Piston Ring Set Parts Questions & Experts Answers

- Q: How should you check and install new piston rings before reassembly on Nissan 300ZX?A:Piston rings end gap must be measured before fitting new piston rings on the cylinder and piston of the engine, so that the piston ring side clearance is precise. Place a new ring set to each piston/connecting rod assembly and then measure the end gap of each set of rings you will have to maintain the same ring set with the same piston and cylinder only when reassembling. Slide the top ring into the first cylinder so that it sits correctly against the walls of the cylinder, do this by pushing it in with the help of the top of the piston. Using a feeler gauge, determine the value of end gap between the ring ends and record the results and check it to the end gap requirement. If any gap is found to be wider or narrower, ensure the right rings are in use. If a gap is small, it should be increased as ends of a ring may contact each other during its functioning in an engine that is devastating. Taking your time to carefully shape the ring ends with a fine toothed file, seeing to the fact the you should only be filing from outside in. If the end gap is way too big, then ensure that the correct size rings have been bought, and the kid wears them correctly. Perform the same process for all rings located in the first cylinder until such time that they match with rings, piston, and cylinder. After the ring end gaps have been chequered and set, the rings should be further fitted on the pistons; beginning from the three-piece oil control ring which should be set with the spacer/expander sliding into the groove, followed by the fitting of the lower side rail without necessarily having to use the piston ring installation tool as it is liable to bend the rail. Once the oil ring components are installed, the user can rotate the both side rails around the groove. Next to it, fit the middle ring with an identification that will distinguish it from the top ring and fit it in such a way that the marked side faces upwards to prevent confusion with the top ring; use a ring expander to avoid the top ring being mixed with the middle one. Lastly, put in the top ring in a similar fashion as the other rings with the identifications mark facing up and proceeded to set in the rest of the pistons and rings with both middle and top rings being different.